-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

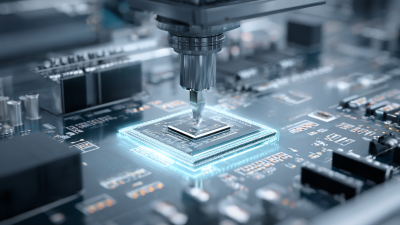

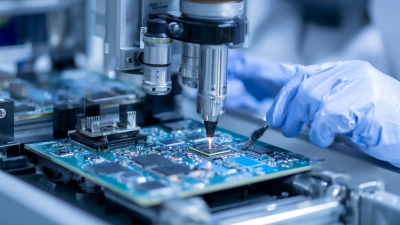

In an increasingly competitive electronics market, the significance of selecting the right Reflow Oven for PCB assembly cannot be overstated. According to a recent report from IPC, the global market for electronics manufacturing services is projected to reach $530 billion by 2025, underscoring the growing demand for efficient and reliable assembly processes. A key component in this procedure is the Reflow Oven, which plays a vital role in soldering surface-mounted components to PCBs by melting solder paste and ensuring optimal connections.

With advancements in technology, the options available for Reflow Ovens are diverse, ranging from convection to vapor-phase systems, each offering unique benefits tailored to specific production needs. Industry experts recommend considering factors such as thermal profile accuracy, energy efficiency, and footprint size when making a decision. A well-chosen Reflow Oven not only enhances product quality but also contributes to reduced production costs and improved workflow efficiency, ultimately leading to higher customer satisfaction. In this guide, we will explore the top 10 Reflow Ovens on the market in 2025, providing insights to help you make an informed decision that aligns with your PCB assembly requirements.

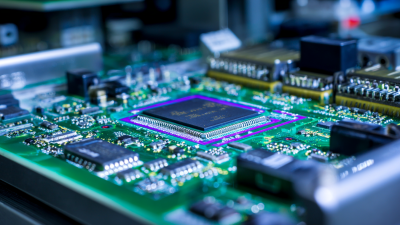

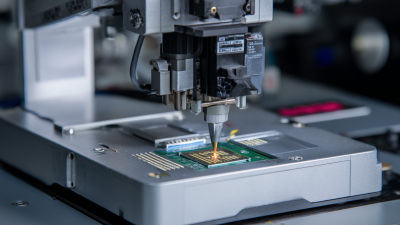

When selecting a reflow oven for PCB assembly, it's crucial to consider several key features that can significantly impact production efficiency and product quality. One of the most critical aspects is the temperature profile control. Accurate temperature control is essential for achieving the desired soldering results without damaging the components. According to a report by IPC, up to 70% of solder defect failures can be attributed to improper thermal management during the reflow process. Thus, ovens featuring advanced monitoring systems that allow for real-time adjustments to the temperature profile can enhance both reliability and yield.

Another vital consideration is the oven’s throughput capacity. As the demand for faster production cycles grows, selecting a reflow oven with an optimal conveyor speed and heating zone length becomes increasingly important. Industry studies indicate that manufacturers with higher throughput rates can achieve up to 30% more productivity compared to their competitors using traditional ovens. Investing in a reflow oven that offers adjustable conveyor speeds and efficient heating zones ensures that your PCB assembly line meets both current and future production requirements efficiently.

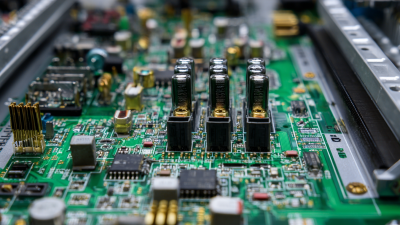

When selecting a reflow oven for PCB assembly, understanding the differences between convection, infrared (IR), and vapor phase ovens is crucial. Convection ovens utilize a fan to circulate hot air throughout the chamber, ensuring even heat distribution across the PCB. This type is highly efficient and suitable for various soldering applications, making it a popular choice for many manufacturers. The ability to adjust the airflow and temperature profiles also enables the optimization of soldering processes for different components.

In contrast, infrared reflow ovens rely on radiant heat to melt solder paste. They are particularly effective for smaller, tightly packed boards where precision heating is essential. The direct heating element allows for rapid temperature changes but can be less forgiving if not monitored carefully. On the other hand, vapor phase ovens operate by generating a vapor that transfers heat to the PCB when it condenses. This method achieves uniform temperature across the board and minimizes thermal stress, making it ideal for sensitive components. Each oven type has its advantages and trade-offs, so the choice should align with specific production needs and the characteristics of the PCBs being assembled.

| Oven Type | Heating Method | Temperature Control | Speed | Best for |

|---|---|---|---|---|

| Convection Oven | Forced Air | Excellent Precision | Medium | General PCB Assembly |

| IR Oven | Infrared Radiation | Good Control | Fast | Small Batches |

| Vapor Phase Oven | Condensation | Exceptional Consistency | Medium | High Mix / Low Volume |

| Hybrid Oven | Convection + IR | Very Good Control | Fast | Versatile Applications |

When choosing a reflow oven for your PCB assembly needs, evaluating size and capacity requirements is crucial. The size of the oven directly influences the scale of production you can achieve. It is essential to assess the dimensions of your PCBs and the volume of boards you intend to process simultaneously. A compact oven may suffice for small-batch or prototype runs, whereas a larger oven will accommodate high-volume production, allowing for multiple boards to be processed in one cycle, thereby improving efficiency.

Moreover, consider the capacity in terms of thermal performance and heating zones. A reflow oven with multiple heating zones offers enhanced temperature control, which is vital for different PCB types and component placements. Additionally, think about your production timeline; if you need to produce a large number of boards quickly, selecting an oven with higher throughput capacity will be beneficial. Ultimately, aligning your chosen reflow oven's size and capacity with your specific PCB production demands will facilitate smoother operations and better product quality.

When selecting a reflow oven for your PCB assembly needs, understanding temperature profiles is crucial. The temperature profile represents the specific temperatures that the PCB components are exposed to during the reflow soldering process. It typically includes preheat, soaking, reflow, and cooling phases, each designed to ensure optimal soldering without damaging the components or the PCB itself. A well-developed temperature profile can prevent common issues such as solder defects, cold joints, or even component damage from thermal stress.

The importance of an accurate temperature profile cannot be overstated. For instance, during the preheat phase, the gradual increase in temperature helps to activate the flux and remove moisture from the components, preparing them for the soldering process. The soaking phase further stabilizes the temperature, allowing for uniform heat distribution across the board. Finally, the reflow phase must reach the melting point of solder quickly and uniformly, ensuring strong connections. Understanding and fine-tuning these phases within your reflow oven will significantly enhance the reliability and performance of your PCB assemblies, ultimately leading to better end products.

When selecting a reflow oven for PCB assembly, it is crucial to strike the right balance between cost and performance. High-performance ovens often come with premium features such as precise temperature control, advanced profiles, and enhanced efficiency. However, these advanced features may not be necessary for every operation, especially for small to medium-sized businesses with limited budgets. Assessing your specific production needs can help identify whether investing in a top-tier model will significantly enhance your output or if a more economical option suffices.

Additionally, consider the long-term implications of your investment. A cheaper oven may lead to higher operational costs due to inefficiencies, resulting in production delays or increased scrap rates. Conversely, a higher-quality reflow oven can facilitate consistent performance, improve yield, and ultimately provide substantial value. Evaluating total cost of ownership, factoring in energy consumption, maintenance costs, and expected lifespan, will aid you in making an informed decision that balances both performance and affordability.