-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In the rapidly evolving landscape of electronics manufacturing, the importance of efficient PCB assembly processes cannot be overstated. As we look ahead to 2025, industry experts emphasize the critical role of Smt Pick Place techniques in optimizing production workflows. Renowned SMT specialist Dr. Emily Tran notes, “The evolution of Smt Pick Place methods is not just about speed; it’s about precision and reliability that drive the future of PCB assembly.”

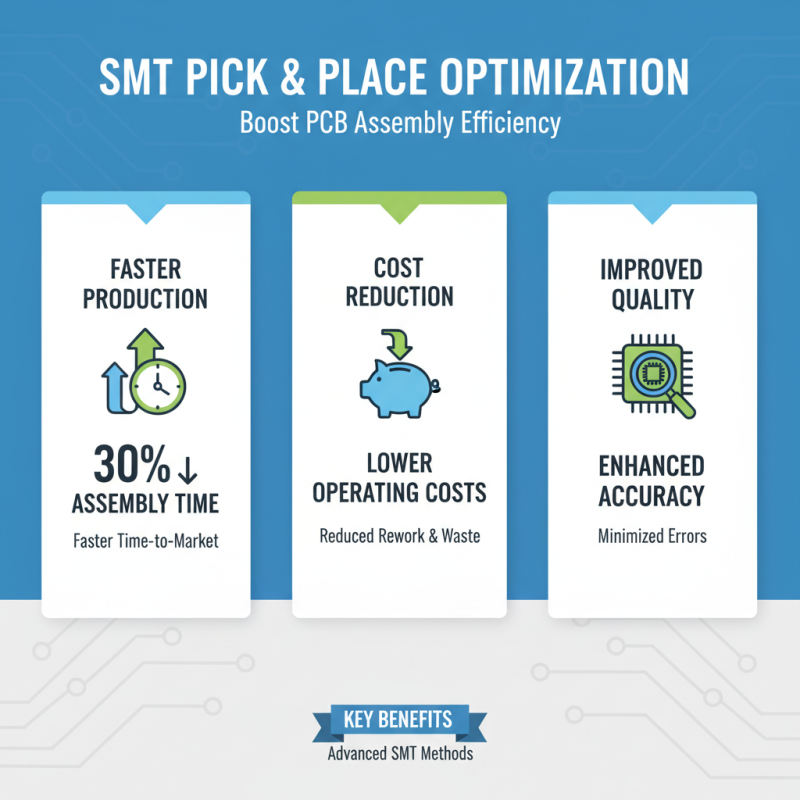

As electronic devices become increasingly complex, manufacturers are challenged to meet high demands for quality and output. The integration of advanced Smt Pick Place technologies offers innovative solutions to these challenges, ensuring that components are placed accurately and swiftly on printed circuit boards. This not only enhances product reliability but also significantly reduces waste and production costs.

In this article, we will explore the top Smt Pick Place techniques anticipated for 2025, highlighting their potential to revolutionize the PCB assembly process. By examining current trends and expert insights, we aim to provide valuable guidance for manufacturers looking to enhance their assembly lines and keep up with the competitive market demands.

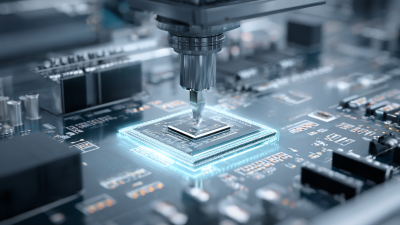

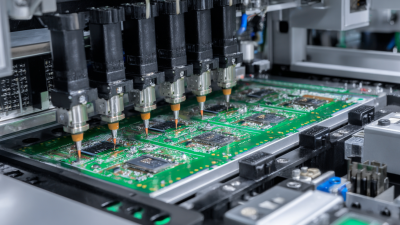

Surface Mount Technology (SMT) has revolutionized the PCB assembly process, greatly enhancing efficiency and productivity. The core of this innovation lies in the pick and place techniques, which involve precise placement of components onto circuit boards. Modern SMT machines utilize advanced robotics and vision systems to accurately position components, reducing the chances of human error and ensuring high-quality assembly. The integration of automated processes not only speeds up production rates but also allows for complex designs to be realized with greater ease.

To optimize the SMT pick and place process, it's crucial to focus on the setup and calibration of the machines. Proper alignment of the nozzle and components, along with regular maintenance checks, can significantly improve placement accuracy. Additionally, utilizing the right feeders for different component types ensures that the process runs smoothly, minimizing downtime.

**Tips:** Always perform a thorough check of the machine settings before starting a production run. This can prevent costly errors and improve overall efficiency. Also, consider conducting regular training sessions for operators to update their skills and knowledge on new technologies and techniques in SMT assembly. Lastly, leveraging data analytics can provide insights into the pick and place performance, helping to identify bottlenecks and areas for improvement in the assembly line.

Efficient Surface Mount Technology (SMT) pick and place methods are critical for optimizing the PCB assembly process. The implementation of advanced pick and place techniques can lead to significant reductions in production time and costs. According to a recent industry report, companies implementing these efficient methods have observed up to a 30% decrease in assembly cycle times, allowing for faster time-to-market for their products. Moreover, optimizing these processes enhances accuracy and minimizes errors, resulting in lower rework rates and overall production waste.

One of the key benefits of employing effective SMT pick and place methods is the improvement in placement accuracy, which is crucial for high-density boards. Research indicates that with modern pick and place machines, placement precision can reach up to 25 microns, vastly increasing the reliability of electronic assemblies. As manufacturers attempt to meet the demands of compact and complex designs, these enhancements in placement technology become vital for maintaining quality standards.

Tips: Regularly calibrate your pick and place equipment to ensure optimal performance and accuracy. Additionally, invest in feeder technology that accommodates various component sizes to enhance flexibility in production. Adopting a preventive maintenance schedule can further prolong the lifespan of your machinery, reducing downtime and supporting continuous production efficiency.

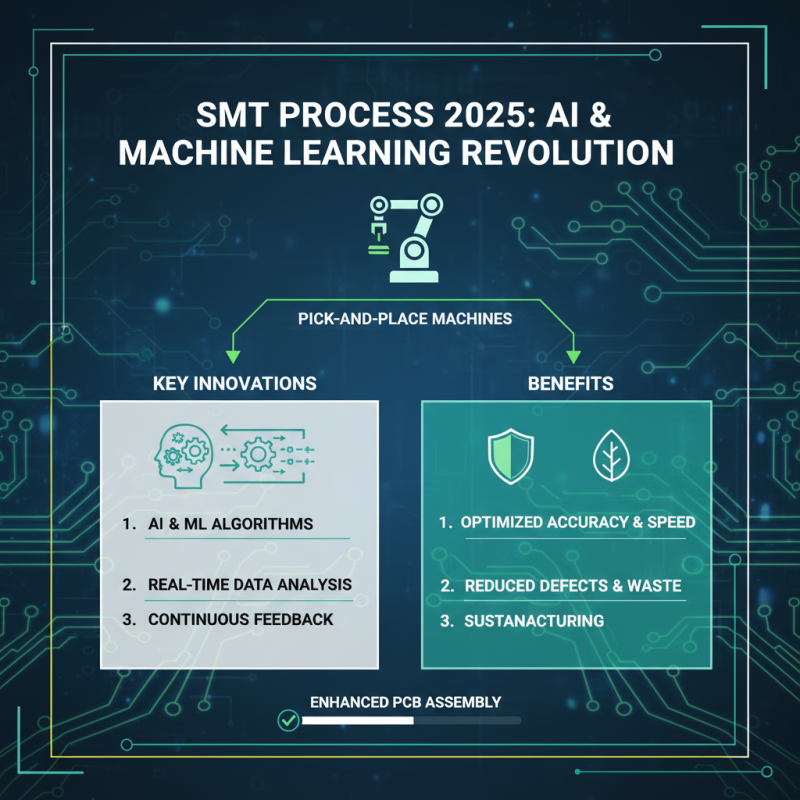

In 2025, the landscape of surface mount technology (SMT) processes is set to be reshaped by a variety of innovative technologies enhancing the efficiency and precision of PCB assembly. One of the most significant advancements is the integration of artificial intelligence and machine learning algorithms into the pick-and-place machines. These technologies enable real-time data analysis, allowing machines to optimize placement accuracy and speed based on continuous feedback from the production line. This not only reduces the rate of defects but also minimizes waste, providing a more sustainable approach to manufacturing.

Another noteworthy development in SMT processes is the implementation of advanced vision systems equipped with deep learning capabilities. These systems are capable of detecting minute deviations in component placement and solder quality, significantly improving the reliability of the final product. By utilizing high-resolution cameras and sophisticated image processing techniques, manufacturers can ensure that every assembled PCB meets stringent quality standards. Furthermore, the rise of automation and robotic systems in the assembly line streamlines operations and reduces labor costs while enhancing safety and efficiency. The combination of these innovative technologies creates a highly responsive and adaptable manufacturing environment, positioning PCB assembly for unprecedented growth and advancement in the industry.

The SMT (Surface Mount Technology) pick and place process is integral to the efficient assembly of printed circuit boards (PCBs). However, manufacturers often face several challenges in this area. One common issue is component misalignment during the placement. Misalignment can occur due to various factors, including variations in component design, inconsistent solder paste deposition, or mechanical inaccuracies in the pick and place equipment. Addressing this challenge requires meticulous calibration of the machines, regular maintenance, and the implementation of advanced vision systems that enhance alignment accuracy.

Another significant challenge in the SMT pick and place process is the handling of delicate components. Many modern PCBs use fragile parts that can easily be damaged during assembly. To mitigate this issue, employing specialized grippers and suction tools tailored for specific component types ensures safer handling. Additionally, optimizing the feeding mechanisms to reduce component jarring during transport can minimize the risk of breakage. By focusing on these solutions, manufacturers can enhance their SMT pick and place efficiency, ultimately leading to a more reliable and effective PCB assembly process.

| Technique | Efficiency Improvement (%) | Common Challenges | Solutions |

|---|---|---|---|

| Automated Pick and Place | 20% | Component misalignment | Use of advanced vision systems |

| Flexible Placement Solutions | 15% | Changing product lines | Modular machine designs |

| High-Speed Pick and Place | 25% | Limited throughput | Implementing optimized feeder systems |

| Enhanced Software Algorithms | 18% | Data processing delays | Using machine learning-based solutions |

| Inventory Management Systems | 22% | Overstock and stockouts | Just-in-time inventory practices |

The landscape of Surface Mount Technology (SMT) assembly is rapidly evolving, driven by advancements in technology and increasing demands for efficiency in printed circuit board (PCB) manufacturing. As we approach 2025, several key trends are emerging that will significantly influence SMT assembly techniques.

One major trend is the integration of artificial intelligence and machine learning into the assembly process. These technologies enable real-time monitoring and data analysis, allowing manufacturers to optimize their operations, reduce errors, and enhance overall productivity.

Another noteworthy trend is the shift towards automation and robotics in SMT assembly lines. Automated systems can handle complex tasks with precision and speed, significantly increasing throughput. These advancements not only streamline the assembly process but also facilitate the handling of smaller components, which are becoming increasingly prevalent in modern electronics. As the industry continues to adopt more sophisticated automation solutions, the role of human operators is expected to evolve, focusing more on oversight and troubleshooting rather than manual assembly tasks.

Lastly, sustainability is becoming a core consideration in SMT assembly techniques. As environmental concerns grow, manufacturers are focusing on implementing eco-friendly practices, such as reducing waste and utilizing energy-efficient systems. Innovations like lead-free soldering and the adoption of recyclable materials are indicative of the industry's commitment to sustainability. As these trends converge, the impact on SMT assembly processes is profound, promising a future characterized by increased efficiency, reduced ecological footprints, and continual advancements in technology.