-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

The world of SMT stencil printers is rapidly evolving. As we anticipate 2026, several trends are emerging that will shape the industry. These innovations are vital for manufacturers aiming to enhance production efficiency and accuracy.

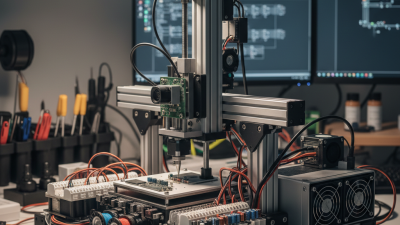

One significant trend is the integration of advanced automation technologies. SMT stencil printers are becoming smarter. They now feature AI-driven processes that streamline printing tasks. Increased precision is expected as well, minimizing errors during production. Additionally, eco-friendly materials and processes are gaining momentum. Sustainable practices are not just a trend; they are becoming a necessity in manufacturing.

Despite these exciting developments, challenges remain. Many companies struggle with adapting to new technologies. Training staff on the latest innovations can be an obstacle. The rapid pace of change may overwhelm some manufacturers. Keeping up with these trends is essential for staying competitive. Ultimately, the future of SMT stencil printers looks promising, but reflection on current practices is crucial.

The year 2026 is poised to bring significant advancements in SMT stencil printing. Emerging technologies are reshaping the landscape, with automation leading the charge. For instance, a recent industry report noted that the adoption of automated stencil printers could enhance efficiency by up to 35%. This shift allows manufacturers to reduce human error and improve print quality.

One notable innovation is the integration of AI in process monitoring. This technology can predict issues before they happen, ensuring a more stable production run. It’s projected that companies using this AI-infused technology may see a reduction in defects by about 20%. However, the transition to these smart systems can pose challenges. Companies must invest in training and infrastructure, which require time and resources.

Tips: Embrace smaller pilot projects to test new technologies. This approach minimizes risk and allows for gradual adjustments. Additionally, ensure your staff is well-prepared to adapt. Training is crucial for maximizing technology effectiveness. Keeping an eye on competitor advancements can provide valuable insights.

| Trend/Innovation | Description | Impact on Industry | Projected Adoption Rate |

|---|---|---|---|

| AI Integration | Utilizing artificial intelligence for pattern recognition and error reduction in stencil printing. | Increased efficiency and reduced wastage, leading to cost savings. | 70% |

| Enhanced Material Usage | Developments in eco-friendly and high-performance stencil materials. | Less environmental impact and improved printing results. | 60% |

| Miniaturization Techniques | Advancements in stencil manufacturing that allow for smaller components to be printed accurately. | Supports the trend towards smaller electronic devices. | 75% |

| Real-Time Monitoring Systems | Implementation of IoT solutions for real-time data collection and analysis during the printing process. | Allows for immediate adjustments, reducing errors and downtime. | 65% |

| Automatic Cleanup Systems | Innovations in automatic cleaning processes for stencils to ensure consistent quality. | Improves productivity and maintains high quality in printing. | 50% |

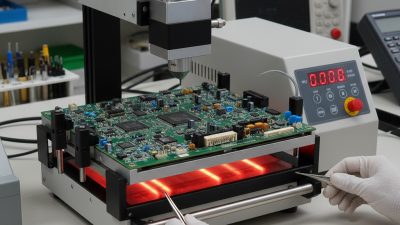

The landscape of SMT stencil printers is evolving rapidly, especially with automation advancements. These innovations promise to enhance printing efficiency significantly. Automation is streamlining processes, reducing labor costs, and improving precision. Machines equipped with smart sensors monitor the workflow, adjusting parameters in real-time. This technology helps to minimize errors and maximize output.

Yet, automation is not without its challenges. Some manufacturers struggle to integrate these new systems into existing processes. The learning curve can be steep. Employees need training to operate complex machines effectively. Misunderstandings about machine capabilities often lead to underutilization. Additionally, not all automation solutions fit every production line. Tailoring technology to specific needs is essential.

Despite these obstacles, the benefits of automation are substantial. Enhanced predictive maintenance leads to fewer downtimes. Automation can also increase production speeds remarkably. The continuous feedback loops provided by smart systems can lead companies to refine their practices further. Companies must remain open to feedback and iterative improvements to truly harness the power of automation.

Sustainability is becoming central in smt stencil printer design and usage. Manufacturers are increasingly focusing on eco-friendly materials. This shift reduces waste and minimizes energy consumption during production. Innovative practices are being adopted to ensure that machines have a longer lifecycle.

Moreover, the implementation of digital technologies plays a crucial role. Smart printing solutions can reduce ink and stencil waste. Many companies are exploring biodegradable components for stencils. This change not only benefits the environment but also inspires new design perspectives. However, moving towards sustainability requires reevaluation of current processes.

There is also a gap in industry readiness. Some companies still rely on outdated equipment that doesn’t align with green practices. Training and adaptation among workers can be challenging. Achieving sustainability goals demands time and persistent efforts. The journey may not be perfect, but each step toward greener solutions is significant.

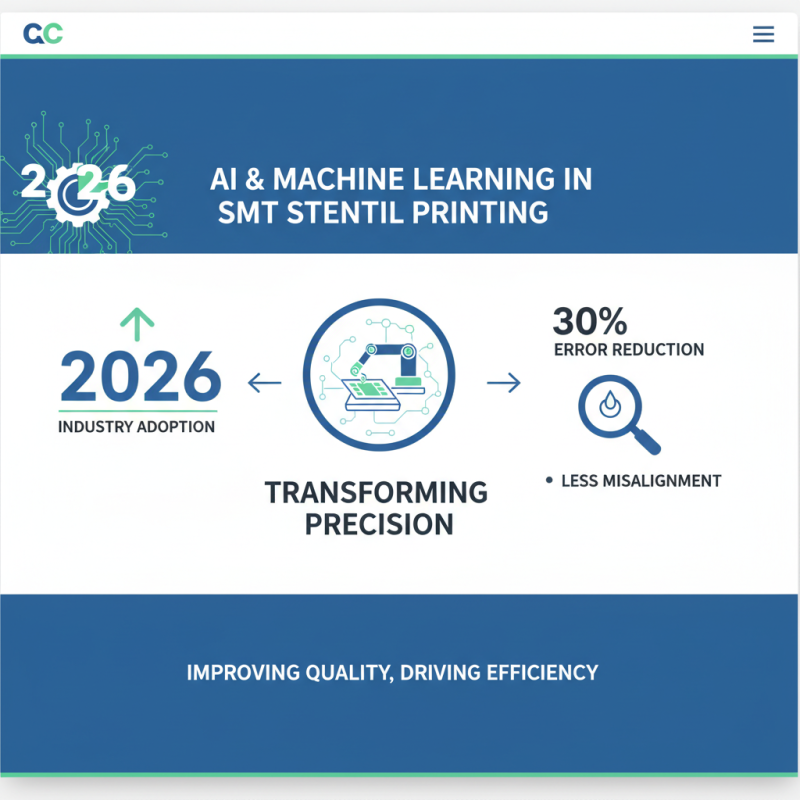

The integration of AI and machine learning in SMT stencil printing is transforming the industry. In 2026, industries are expected to embrace these technologies more fully. Reports indicate that AI can improve the precision of printing processes, reducing errors by up to 30%. This addresses significant issues, such as misaligned prints.

However, the journey is not without challenges. Data quality remains a concern. Many companies struggle to collect clean data for training AI models. Inconsistent datasets can lead to inaccurate predictions. As the demand for higher efficiency rises, this inconsistency may become a bottleneck.

Industry reports suggest that implementing AI-driven systems can boost production speed by approximately 25%. However, adapting to these advanced technologies demands a skilled workforce. Training employees to work with AI tools presents a hurdle. Without proper training, the potential benefits may not be fully realized. Balancing technology with human expertise is crucial for success.

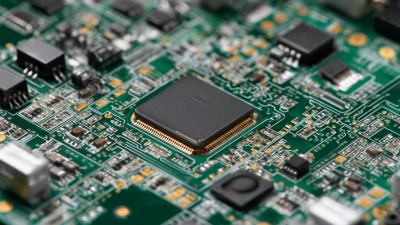

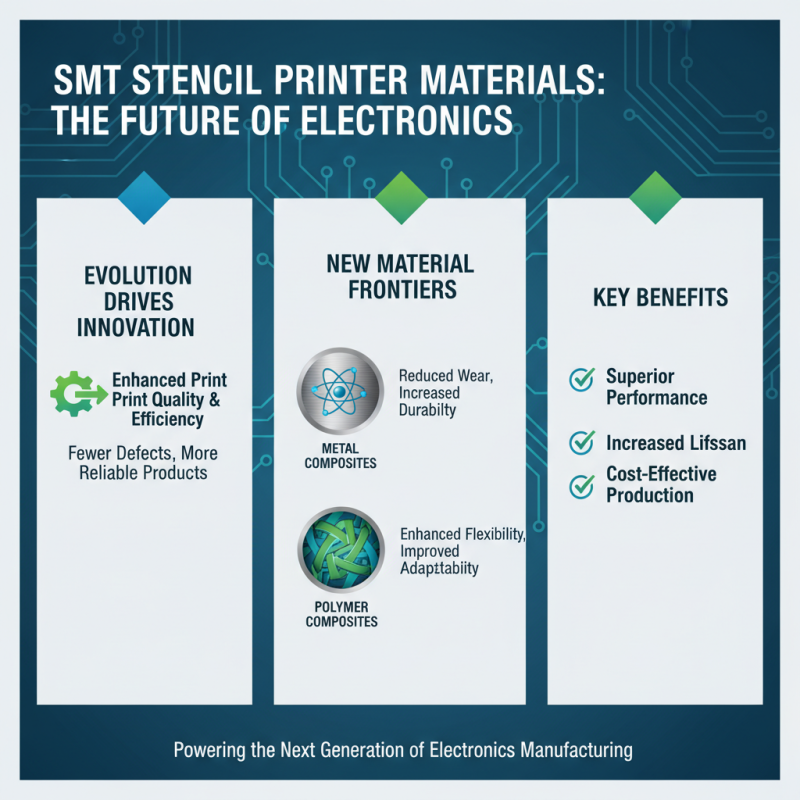

As the electronics industry evolves, material innovations for SMT stencil printers become crucial. Developers are exploring new options to enhance print quality and efficiency. Advances in metal and polymer composites show promise. These materials can reduce wear and enhance flexibility during the printing process. This improved performance can lead to fewer defects and more reliable products.

Some innovations may face challenges. For example, metal stencils offer precision but can be cost-prohibitive. On the other hand, polymer materials may lack the necessary durability. This balance between price and performance remains a key area for development. Testing these materials under various conditions is essential for understanding their true potential.

Eco-friendly materials are also gaining attention. They can reduce waste and improve overall sustainability. However, finding materials that meet performance standards without compromising environmental responsibility is complex. Research in bio-based materials is ongoing, but viable solutions are still developing. The journey toward improved printing performance continues, with many questions left unanswered.