-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In today's competitive manufacturing landscape, the Aoi Inspection Machine has emerged as a vital tool for quality control. Industry expert Dr. Emily Chen states, "Precision in inspection is no longer optional; it's essential." This resonates with manufacturers striving for excellence. Quality control affects customer satisfaction and brand reputation.

The adoption of Aoi Inspection Machines enhances inspection speed and accuracy. These machines detect defects unseen by the human eye. However, some operators may struggle with the technology at first. This learning curve can lead to initial inefficiencies. Yet, overcoming these challenges often results in significant long-term benefits.

Through consistent use, Aoi Inspection Machines help reduce waste and improve overall production rates. They provide valuable data for informed decision-making, but navigating this data can be complex. Manufacturers must remain vigilant, continually assessing machine performance and accuracy. The journey toward seamless quality control is ongoing.

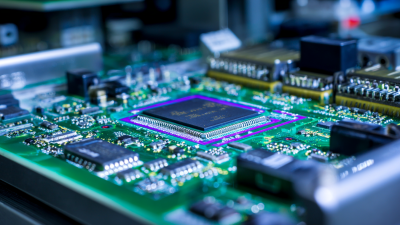

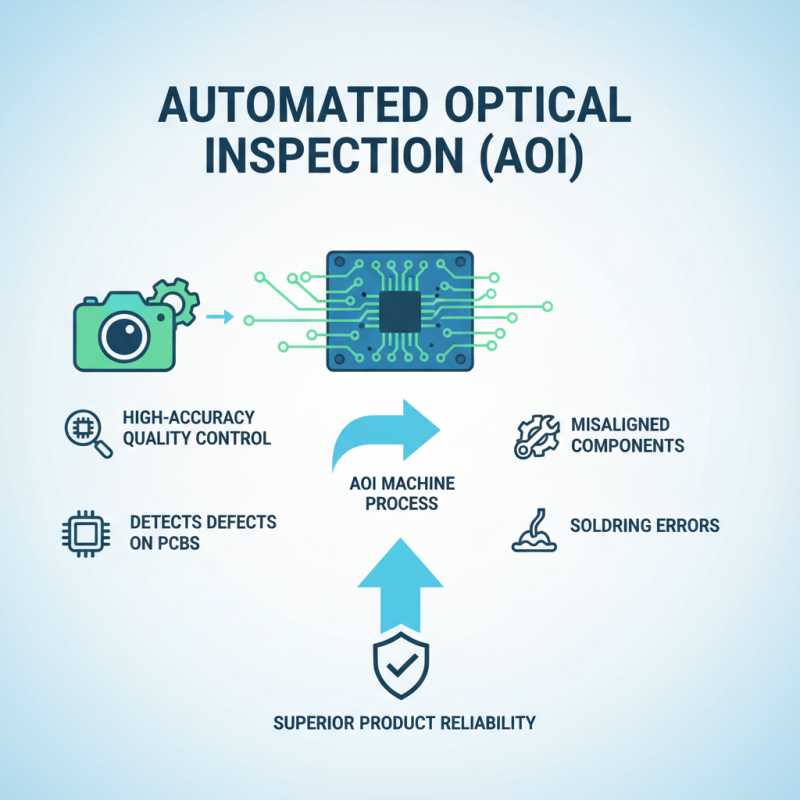

Automated Optical Inspection (AOI) machines play a crucial role in modern manufacturing. They provide a high level of accuracy in quality control. These machines use advanced cameras to detect defects on printed circuit boards (PCBs). They help identify issues like misaligned components or soldering errors. This leads to better product reliability.

One notable advantage is speed. AOI machines perform inspections much faster than human workers. This efficiency allows for quick adjustments in the production line. However, these machines may misinterpret some defects due to complex designs. Therefore, periodic human review is necessary to ensure quality.

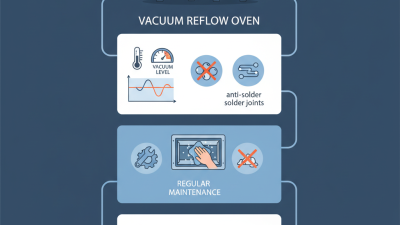

Tip: Always calibrate the AOI machines regularly for optimal performance. Regular maintenance can prevent many common errors.

Another benefit is data collection. AOI machines can log defect types and frequencies. This data can help in refining manufacturing processes. Yet, the data analysis can be overwhelming. Companies should consider training staff to use this information effectively.

Tip: Encourage team discussions around AOI data; it can lead to innovative solutions. Sharing insights can improve team collaboration and minimize the risk of overlooked defects.

Aoi inspection machines are game changers in quality control. They greatly enhance accuracy and precision. This is essential for manufacturers aiming for high standards. These machines utilize advanced imaging technology. They detect defects that are invisible to the naked eye. Aoi machines can identify misalignments, missing components, or soldering issues. This capability ensures products meet rigorous quality requirements.

Implementing Aoi machines introduces new challenges. Staff must be trained to operate complex systems. The initial setup can be time-consuming and may require fine-tuning. Data analysis becomes crucial as well. Machines generate extensive data that must be interpreted correctly. Misinterpretation can lead to unnecessary adjustments or overlooked flaws.

Creativity in problem-solving is critical. Every production line is different. Aoi machines must be tailored to suit specific needs. Sometimes, they may miss subtle defects. Continuous improvements and periodic assessments are necessary. Adapting to evolving technologies can be daunting. However, the potential rewards of increased quality make it worthwhile. Quality control is not just a checkbox; it’s a commitment.

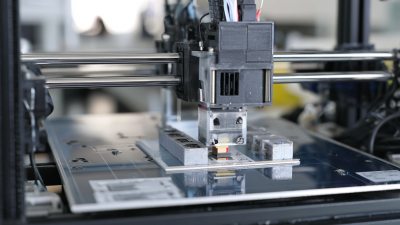

Automating inspection processes with Aoi inspection machines greatly enhances time efficiency in quality control. Traditional inspection methods are often slow. They require manual labor and time-consuming checks. By automating this process, companies can significantly reduce inspection time. Machines can analyze products quickly and accurately, identifying defects that may go unnoticed by human inspectors.

Investing in Aoi technology is a smart move for any production line. It streamlines workflows and minimizes delays. However, reliance on machines can also lead to oversight. Regular calibration and maintenance are essential to keep machines performing efficiently. Neglecting this can result in increased errors. Quality control systems need continuous updates to adapt to changing standards.

Tips: Train your staff to work alongside machines. This enhances understanding and cooperation. Monitor performance metrics closely. Adjust inspection parameters based on insights gained. Embrace the advantages of automation, but remember to keep the human element in quality control alive. Balancing technology with human oversight is key to maintaining high standards.

Automated Optical Inspection (AOI) technology plays a pivotal role in modern manufacturing. Its capability to enhance quality control while driving cost savings cannot be overstated. An industry report indicates that companies utilizing AOI report a reduction in rework costs by approximately 30%. This translates to significant savings, particularly in high-volume production environments where mistakes can lead to financial strain.

Minimizing waste is another key advantage of AOI systems. By detecting defects early, manufacturers can avoid the costly process of scrapping faulty products. Some studies suggest that companies experience an up to 50% decrease in material waste through effective AOI implementation. This leads to improved profitability and sustainability, as less material goes to waste. Although AOI technology is powerful, it does not eliminate all errors. There are instances where it may miss subtle defects, leading to further scrutiny and adjustment.

The integration of AOI systems requires a shift in workforce mentality too. Training staff to adapt to these new technologies is essential. Some workers may resist the change due to fear of job displacement or unfamiliarity with the systems. Addressing these human factors is crucial. The potential for cost savings and efficiency is immense, but so is the need for reflection and adaptation within the team.

The importance of regulatory compliance in manufacturing cannot be overstated. Aoi inspection machines enhance adherence to industry standards. According to a recent report by the International Organization for Standardization (ISO), over 75% of manufacturers face challenges in meeting compliance benchmarks. This is where Aoi machines can be crucial.

These machines meticulously inspect products for defects, ensuring that quality remains high. A study by the Quality Management Association revealed that manufacturers using Aoi technology saw a 30% decrease in compliance issues. This improvement is instrumental in avoiding costly fines and potential recalls. However, not all organizations invest in such technology due to budget constraints or lack of awareness.

Moreover, while Aoi systems provide significant benefits, they are not infallible. False positives can occur, leading to unnecessary waste. A balance must be struck between automated detection and human oversight. Therefore, the integration of Aoi machines should be approached with careful consideration. Ultimately, their role in compliance is transformational, yet there remains room for improvement in implementation strategies.