-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

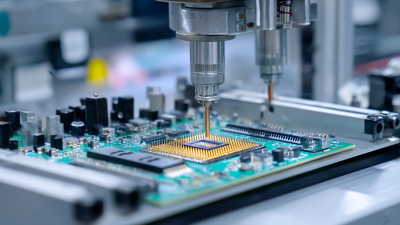

In the rapidly evolving landscape of manufacturing, efficiency and precision are paramount. The adoption of advanced technologies is essential to keep pace with industry demands. A significant development in this arena is the utilization of Radial Insertion Machines, which have revolutionized the way components are assembled. According to a recent report by MarketsandMarkets, the global market for automated machinery is projected to reach $250 billion by 2025, driven by the growing need for efficiency and lower labor costs.

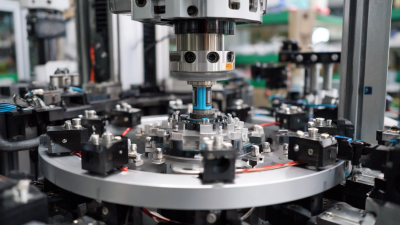

Radial Insertion Machines stand out for their ability to streamline production processes, significantly reducing labor time while enhancing precision. These machines employ a unique mechanism that allows for multiple components to be inserted radially in a single operation, thereby minimizing manual handling and potential errors. A study by the Association for Manufacturing Technology indicates that companies that integrate such automated solutions can achieve up to a 40% increase in productivity and a remarkable reduction in assembly errors.

As manufacturers strive for competitive advantage, the strategic implementation of Radial Insertion Machines becomes imperative. Not only do they promise substantial operational efficiencies, but they also align with industry 4.0 initiatives aimed at automation and data exchange in manufacturing technologies. This article delves into the top five benefits of employing Radial Insertion Machines, highlighting their pivotal role in shaping the future of efficient manufacturing.

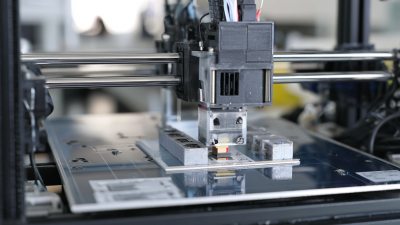

Radial insertion machines have revolutionized manufacturing processes by significantly enhancing production speed. These advanced machines are designed to efficiently insert components into various substrates, minimizing downtime that often occurs with traditional methods. By automating the insertion process, manufacturers can achieve higher throughput, allowing them to meet growing market demands without compromising on quality. This increased speed translates to a remarkable boost in overall productivity, enabling businesses to maximize their output within shorter time frames.

Radial insertion machines have revolutionized manufacturing processes by significantly enhancing production speed. These advanced machines are designed to efficiently insert components into various substrates, minimizing downtime that often occurs with traditional methods. By automating the insertion process, manufacturers can achieve higher throughput, allowing them to meet growing market demands without compromising on quality. This increased speed translates to a remarkable boost in overall productivity, enabling businesses to maximize their output within shorter time frames.

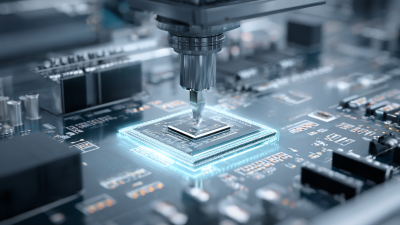

Moreover, the precision offered by radial insertion machines further contributes to production efficiency. By ensuring accurate placement of components, these machines reduce the likelihood of defects and rework, which can delay production schedules. Additionally, the integration of these machines into existing manufacturing lines often leads to smoother workflows. With less time spent on manual handling and assembly, employees can focus on other critical tasks, enhancing operational efficiency across the board. Overall, the combination of speed and precision offered by radial insertion machines positions manufacturers to achieve significant competitive advantages in today's fast-paced market.

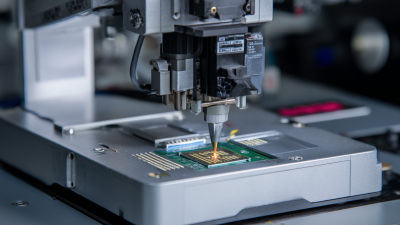

Radial insertion machines have revolutionized manufacturing processes by significantly enhancing precision and accuracy. Traditional methods of component insertion often come with variability, leading to misalignment and errors that can compromise product quality. In contrast, radial insertion machines utilize advanced technology to ensure that components are placed exactly where they need to be, minimizing the risk of defects and rework.

The ability to achieve high levels of precision is especially critical in industries where even the smallest deviations can have serious implications. By automating the insertion process, these machines eliminate human error and create a consistent manufacturing output. As a result, manufacturers can meet stringent quality standards while also increasing production speed. This not only streamlines operations but also enhances the overall reliability of the end product, making radial insertion machines an indispensable asset in today’s efficient manufacturing landscape.

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Increased Speed | Radial insertion machines can perform tasks faster than manual methods. | Higher production rates, reducing lead times. |

| Enhanced Accuracy | These machines offer precise placement of components. | Reduction in defects and rework costs. |

| Consistency | Automated processes ensure uniformity in manufacturing. | Improved product quality and reliability. |

| Cost Efficiency | Reduction of labor costs and material waste. | Increased profit margins and competitive pricing. |

| Flexibility | Able to handle various component sizes and types. | Adaptable to changing production needs and market demands. |

The application of radial insertion machines in manufacturing is transforming the industry landscape, particularly in terms of labor costs. By automating the insertion processes, companies can significantly reduce their reliance on manual labor. According to a report from the International Federation of Robotics, automation can lead to a 25-50% reduction in labor costs, allowing manufacturers to allocate resources more efficiently. This not only enhances productivity but also maximizes profitability.

Tips for manufacturers considering the shift to automated solutions include conducting a thorough cost-benefit analysis. Understand the initial investment required for radial insertion machines versus the long-term savings on labor. Additionally, involve your workforce early in the transition process; this promotes a smoother integration of automation and helps alleviate concerns about job displacement.

Moreover, training programs should be implemented to upskill employees, enabling them to operate advanced machinery and handle maintenance tasks. As per the The World Economic Forum, upskilling can increase employee retention rates by up to 30%. Therefore, striking a balance between automation and workforce development is essential for a sustainable and efficient manufacturing operation.

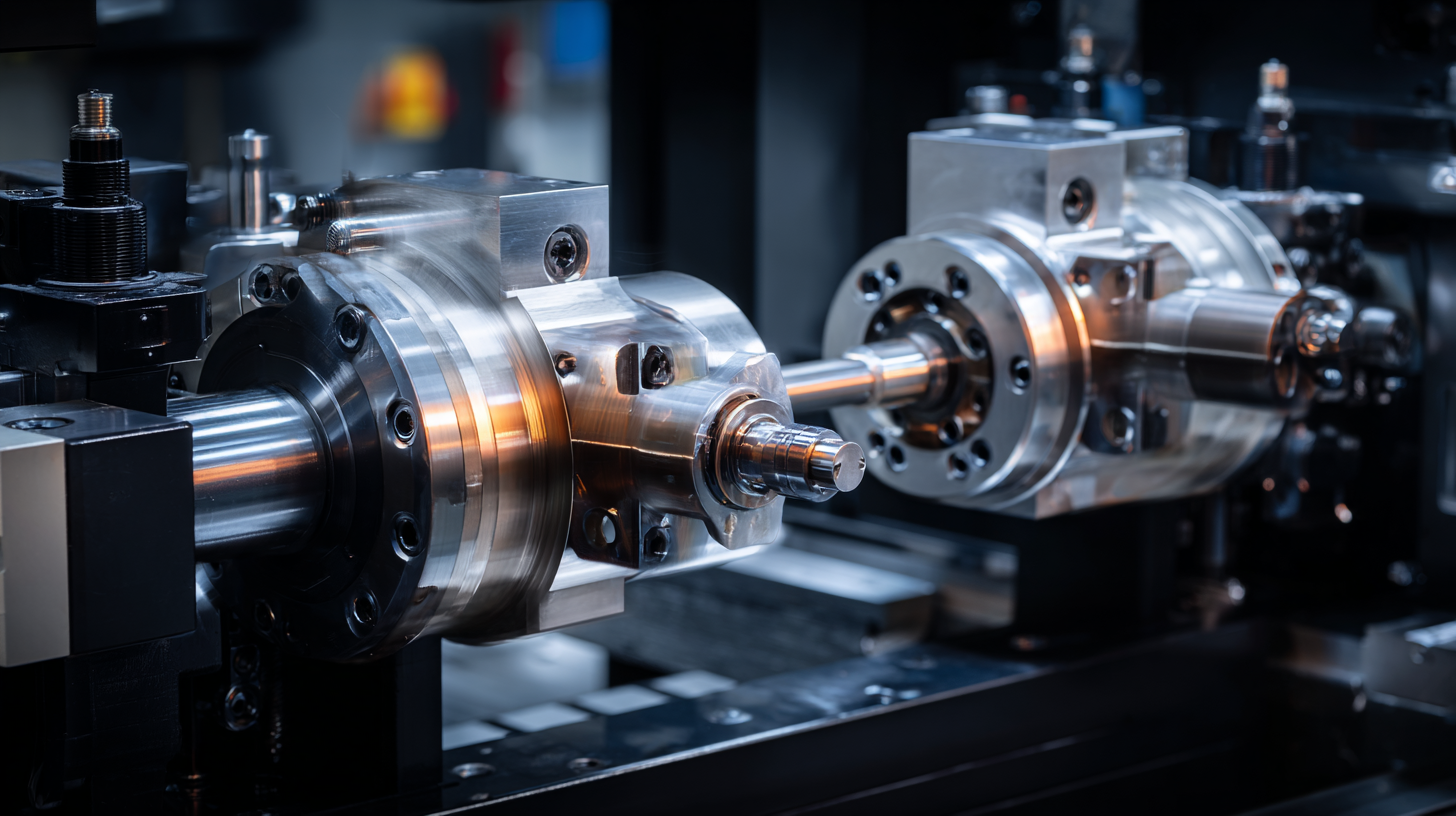

Radial insertion machines are gaining popularity in manufacturing environments due to their remarkable flexibility and adaptability. These machines can be easily adjusted to accommodate various component sizes and types, allowing manufacturers to adapt to changing production demands without significant downtime. This versatility is particularly beneficial in industries where product specifications frequently evolve or where small batch production is required. With modular designs, radial insertion machines enable quick changeovers, streamlining processes while reducing waste and operational costs.

Moreover, the ability to handle multiple applications makes radial insertion machines an invaluable asset in a diverse manufacturing landscape. They can efficiently manage tasks ranging from electronics assembly to automotive components, enabling manufacturers to diversify their product lines with minimal investment. As companies seek to remain competitive in a fast-paced market, the adaptability of these machines ensures they can meet the unique challenges of each project, ultimately improving efficiency and productivity across the board. With their inherent flexibility, radial insertion machines represent a strategic choice for manufacturers aiming to enhance their operational capabilities.

The implementation of radial insertion machines significantly enhances product quality and consistency across manufacturing batches. These machines are designed to automate the insertion process with precision, reducing human error and variations that often lead to product inconsistencies. By maintaining exact specifications and repeatable operations, companies can ensure that each product meets stringent quality standards, thereby minimizing defects that can arise from manual handling.

Moreover, the uniformity achieved through radial insertion machines fosters a reliable production flow. When each unit adheres to the same quality parameters, it allows for better predictability in performance across different batches. This consistency not only boosts customer satisfaction but also strengthens brand reputation in the market. Businesses can respond to consumer demands with confidence, knowing that their products maintain a level of excellence that sets them apart from competitors. As a result, the adoption of these machines not only streamlines manufacturing processes but also delivers significant improvements in product quality and overall operational efficiency.