-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

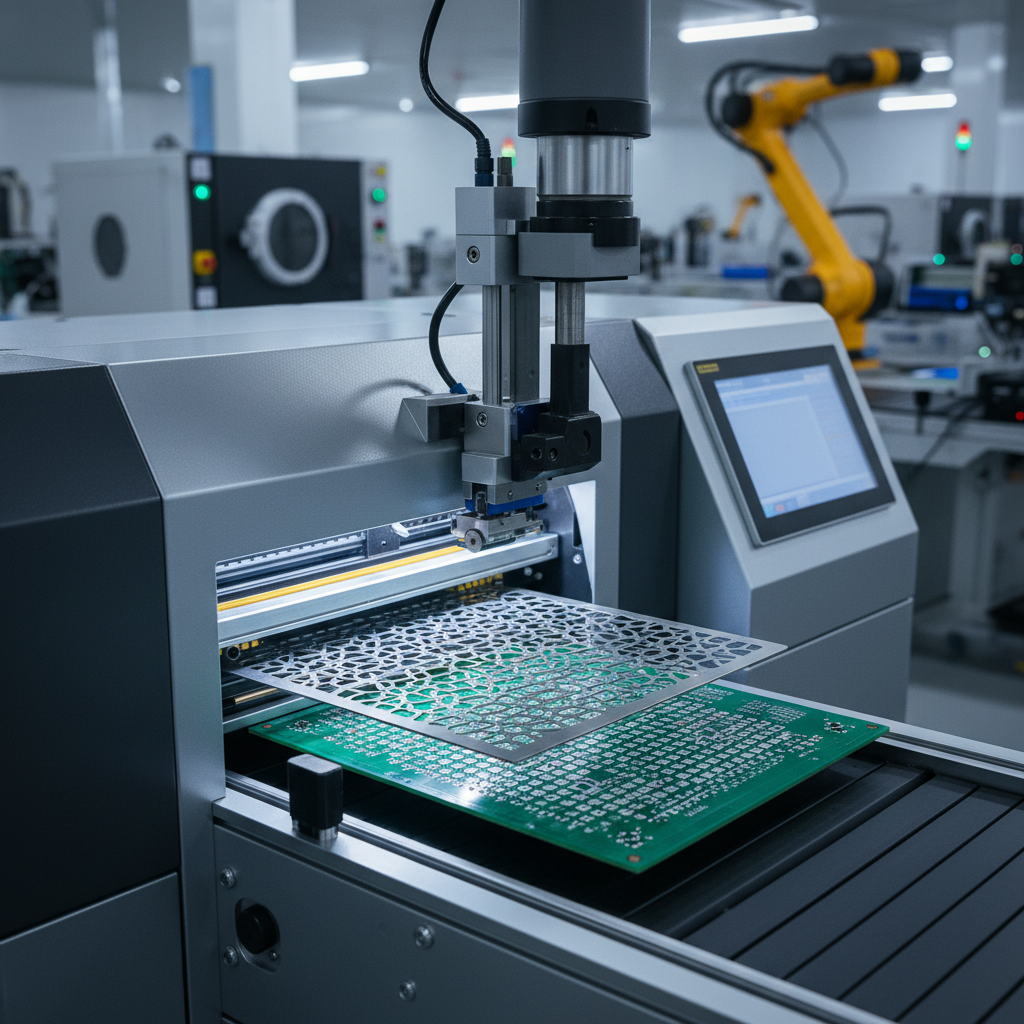

In the rapidly evolving world of electronics manufacturing, the demand for precision and efficiency continues to rise. According to a recent report by Smithers Pira, the global market for printed circuit boards (PCBs) is projected to reach $75 billion by 2026, driven largely by advancements in technology and the increasing complexity of electronic devices.

In this context, the role of the PCB stencil printer has become crucial, as it directly impacts the quality and speed of PCB assembly.

A high-quality PCB stencil printer not only facilitates the accurate application of solder paste but also enhances productivity by reducing the likelihood of errors during the fabrication process.

Industry experts highlight that manufacturers utilizing advanced stencil printing technologies can achieve defect rates as low as 0.1%, significantly improving yield rates and reducing waste. This underscores the importance of selecting the right PCB stencil printer for businesses aiming to maintain competitiveness in the market.

This article will explore the top 5 PCB stencil printers of 2023, focusing on their capabilities, features, and how they can meet the demands of modern precision manufacturing. By examining these leading options, manufacturers can make informed decisions to elevate their production processes and ensure high-quality output in their PCB assembly operations.

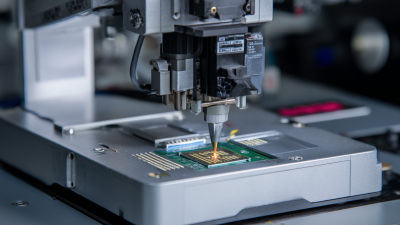

When selecting a PCB stencil printer, several key features must be considered to ensure precision manufacturing and optimal performance. Firstly, the printer's alignment system plays a crucial role; devices equipped with optical alignment technology enhance the placement accuracy of solder paste, significantly reducing misalignment errors. According to a market analysis by IPC, 70% of assembly defects stem from inadequate printing techniques, highlighting the importance of precision in the printing process.

Additionally, print speed and throughput are essential metrics that affect overall productivity. High-performance machines can achieve speeds of over 300 mm/sec, which is crucial for meeting the increasing demands in the electronics industry. Research from IPC indicates that manufacturers prioritizing speed without compromising quality report a 30% increase in overall efficiency. Finally, consider the stencil material and thickness, as these directly influence the volume of solder paste transferred. A report by Technavio found that using high-quality stainless steel stencils can improve paste release capabilities by up to 25%, demonstrating a substantial impact on manufacturing precision.

In the realm of precision manufacturing, selecting the right PCB stencil printer is crucial for achieving optimal results.

This comparative analysis delves into leading models from various manufacturers, highlighting their unique features and performance metrics. Factors such as print speed, accuracy, and ease of use are taken into consideration, giving a holistic view of what each machine brings to the table.

Advanced technologies like laser alignment and automated cleaning systems are evaluated, transforming the capabilities of these printers and making them indispensable in modern manufacturing environments.

Furthermore, user feedback and industry benchmarks are considered to present a comprehensive overview of each printer's reliability. The analysis emphasizes models that not only promise excellent print quality but also deliver on the operational efficiency that manufacturers increasingly demand.

By examining these ten top printers, businesses can make informed decisions tailored to their specific needs, ensuring that their production processes remain competitive and cutting-edge in the fast-evolving landscape of electronics manufacturing.

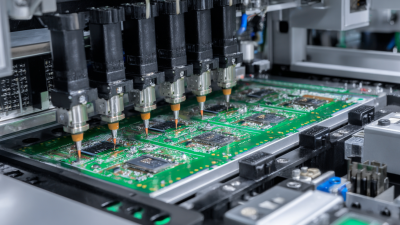

Digital PCB stencil printers have revolutionized the manufacturing process by enhancing precision and efficiency.

One of the key advantages of these printers is their ability to produce high-quality stencils with intricate designs, ensuring accurate paste deposition on printed circuit boards.

This precision reduces the risks associated with manual processes, such as misalignment and inconsistent paste application, leading to higher yield rates and improved product reliability.

Moreover, digital stencil printers offer greater flexibility in production. They allow for quick adjustments and modifications to stencil designs, accommodating varying production needs and reducing downtime.

This adaptability is crucial in today's fast-paced manufacturing environment, where rapid prototyping and shorter production cycles are essential.

Additionally, the use of digital technology enables better integration with automated assembly lines, streamlining the overall manufacturing process and contributing to cost savings in labor and material waste.

As manufacturers strive for excellence, the advantages offered by digital PCB stencil printers will continue to play a pivotal role in precision manufacturing.

Maintaining a PCB stencil printer is crucial for achieving optimal performance and ensuring the high precision required in surface-mount technology (SMT) manufacturing. One of the key elements is the stencil cleaning process, which significantly influences the quality of solder paste application. Research indicates that improper cleaning can lead to defects such as insufficient paste volume or mean shift variance, which can detrimentally affect overall productivity. A recent report highlighted that regular cleaning cycles can improve printing accuracy by up to 15%, thus reducing waste and operational costs.

Additionally, implementing a predictive maintenance model, such as the one developed using recurrent neural networks, allows manufacturers to anticipate when cleaning is necessary based on real-time operational data. This proactive approach not only enhances the efficiency of the stencil printing process but also extends the lifespan of the equipment. Furthermore, the integration of advanced technologies in monitoring the stencil printing process emphasizes the importance of systematic maintenance, ensuring both reliability and precision critical for modern PCB manufacturing industries. By prioritizing these practices, manufacturers can bolster their production capabilities while maintaining quality standards essential for competitive market positioning.

| Model | Print Area (mm) | Layer Thickness (μm) | Speed (mm/s) | Price (USD) |

|---|---|---|---|---|

| Model A | 300 x 400 | 100 | 20 | 1500 |

| Model B | 250 x 350 | 120 | 25 | 1200 |

| Model C | 400 x 500 | 90 | 15 | 1800 |

| Model D | 300 x 450 | 110 | 18 | 1600 |

| Model E | 350 x 400 | 125 | 22 | 1400 |

| Model F | 400 x 500 | 80 | 30 | 2000 |

| Model G | 275 x 375 | 150 | 19 | 1300 |

| Model H | 330 x 460 | 95 | 24 | 1750 |

| Model I | 310 x 450 | 115 | 21 | 1600 |

| Model J | 280 x 380 | 100 | 23 | 1450 |

The landscape of PCB stencil printing technology is evolving rapidly, driven by the need for increased precision and efficiency in manufacturing. One of the emerging trends is the incorporation of automation and robotics. Automated stencil printers are designed to minimize human error and enhance production speed, allowing manufacturers to achieve higher throughput without compromising quality. These systems often utilize advanced imaging technologies to ensure perfect alignment and consistent paste deposition, which is crucial for meeting the stringent requirements of modern electronic devices.

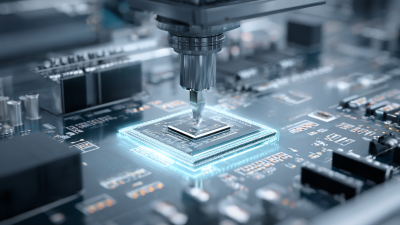

Additionally, the integration of artificial intelligence (AI) and machine learning in stencil printing processes is reshaping the industry. AI-driven systems can analyze production data in real time, optimizing printing parameters and predicting potential failures before they occur. This proactive approach not only reduces downtime but also significantly lowers waste by ensuring materials are used more efficiently.

As manufacturers strive for greater sustainability and cost-effectiveness, these technological advancements are setting the stage for a new era in PCB stencil printing, ultimately leading to more reliable and high-performance electronic assembly.