-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In the fast-paced world of manufacturing, Radial Insertion Machines have become crucial for efficient component placement. According to a recent report by the International Federation of Robotics, production lines are increasingly adopting these machines, leading to a 30% boost in assembly speed. The demand for precision and speed in electronic manufacturing is at an all-time high.

Expert in the field, Dr. Emily Carter, emphasizes the importance of advanced technology. She states, "Radial Insertion Machines simplify complex placements, ensuring high accuracy at lower costs." However, the industry faces challenges. Many machines are not optimized for diverse product ranges, leading to inefficiencies. The task for manufacturers is to find a balance between speed and versatility.

Investing in the right Radial Insertion Machine could yield significant returns. Yet, companies often overlook the need for regular updates and maintenance. This oversight can lead to productivity losses. As the market evolves, continuous learning is essential. The future belongs to those who adapt quickly and strategically.

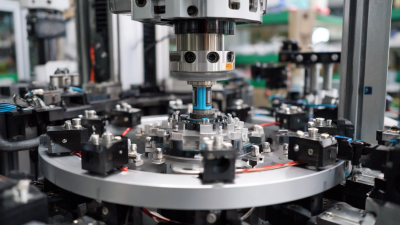

Radial insertion machines play a vital role in the manufacturing realm. These machines facilitate the placement of electronic components onto printed circuit boards. By automating the insertion process, they enhance efficiency and precision. High-speed insertion reduces labor costs and increases production rates, making them indispensable in modern electronics assembly.

Despite their advantages, there can be challenges. Not every component fits perfectly. Sometimes, alignment issues arise, which may lead to defects in placement, requiring manual corrections. In some cases, programming these machines can be complex, posing a learning curve for operators. The balance between speed and accuracy is crucial. Operators must continually refine their processes to minimize errors.

Adopting radial insertion machines also requires consideration of maintenance. Regular checks are essential to keep the machines running smoothly. Downtime can disrupt production schedules. Reflection on these aspects encourages manufacturers to invest in training and support for employees. This investment can ultimately lead to a more efficient and reliable assembly process.

When choosing a radial insertion machine, consider adjustable settings. Flexibility is key. Machines with various speed options allow for more precise component placement. Check if the machine supports different lead sizes. This function increases versatility.

Pay attention to the machine's footprint. A compact design may save space in a busy workspace. However, if a machine is too small, it might limit functionality. Think about accessibility as well. Operators must reach all controls easily. Delays can occur if a machine is hard to operate.

Tips: Always review the integration capabilities. A machine that can work with existing equipment can streamline your production. Also, ensure it has good customer support. Ideally, you want a reliable service team to assist with troubleshooting. Lastly, look for user reviews. They often reveal details you might not consider.

| Machine Model | Placement Speed (CPH) | Component Size Range (mm) | Accuracy (mm) | Automatic Calibration |

|---|---|---|---|---|

| Model A | 5,000 | 1.0 - 20.0 | ±0.02 | Yes |

| Model B | 6,500 | 0.8 - 15.0 | ±0.03 | Yes |

| Model C | 4,200 | 1.5 - 25.0 | ±0.01 | No |

| Model D | 7,000 | 0.5 - 18.0 | ±0.02 | Yes |

| Model E | 5,800 | 1.0 - 22.0 | ±0.025 | Yes |

When considering radial insertion machines, several noteworthy models stand out in the market. These machines play a crucial role in the assembly process, particularly for electronic components. Efficient component placement can significantly boost productivity. Some machines feature advanced mechanisms that allow for quick adjustments, enhancing user experience. It's essential to assess their speed and precision.

A few top models may lack sufficient user-friendly interfaces or require extensive training. Their complexity can hinder performance initially. However, their long-term benefits often outweigh the initial learning curve. Some machines offer programmable features, enabling greater flexibility in production. Yet, these options sometimes come with a cost to simplicity.

Numerous brands provide a range of models suited for diverse manufacturing needs. Their designs vary, focusing on durability and accuracy. It's crucial to check user reviews and reliability before making a decision. The right machine should not only fit your current requirements but also adapt to future needs. Investing in a suitable radial insertion machine is a thoughtful step toward improving efficiency and quality in production.

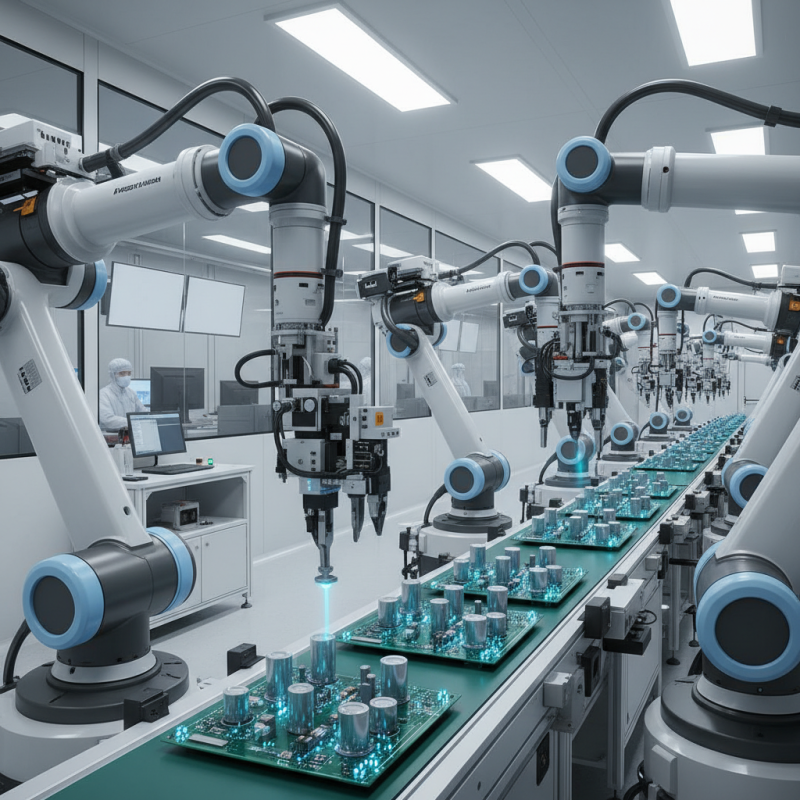

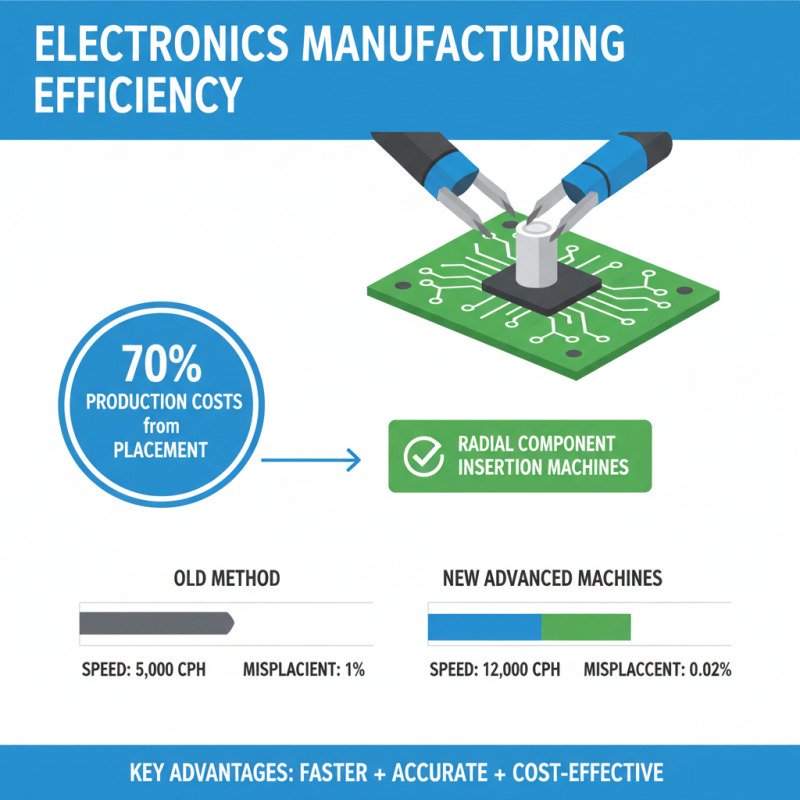

In today’s electronics manufacturing landscape, the need for efficient component placement is paramount. Recent studies indicate that up to 70% of production costs stem from placement accuracy and speed. A comparative analysis reveals that machines designed for radial component insertion offer significant advantages. These machines can achieve placement speeds of 12,000 components per hour, enhancing productivity significantly. Moreover, design improvements have led to a decrease in misplacement rates, now averaging around 0.02%.

But there are challenges that persist. Complex components still require skilled operators for optimal placement. Even with advanced technology, quality can be inconsistent, underscoring the necessity for continuous training. A recent report highlighted that companies often overlook routine maintenance, causing machine downtimes. As a result, performance can dip by up to 15%. Investing in comprehensive training programs and systematic checks can help mitigate these risks.

Additionally, the industry faces pressure to adapt. The rapid pace of technology evolution demands that machines keep up. When evaluating performance, it's crucial to consider scalability. Some machines may excel in speed but lack flexibility for different component sizes or types. Balancing these factors remains a concern for many manufacturers. Addressing these complexities will be essential for achieving long-term efficiency and effectiveness in component placement.

Radial insertion machines are crucial in PCB manufacturing. They enhance productivity by placing components accurately. However, proper maintenance is essential to extend their lifespan. Industry reports suggest that effective maintenance can increase machine life by up to 30%. Neglecting upkeep may lead to malfunctions and costly repairs.

To keep these machines running smoothly, regular cleaning is vital. Dust and debris can obstruct moving parts. Schedule weekly cleanings to prevent buildup. Additionally, check alignment frequently. Misalignment can lead to defective placements. A simple adjustment could save time and money in the long run.

Lubrication is another important step. Using the right lubricants on moving parts can reduce friction, thus improving efficiency. Monitor wear and tear regularly. Components that show signs of wear should be replaced promptly. Delaying replacement can lead to bigger issues. Consider keeping a log of maintenance activities. This can provide insights into common problems. Overall, taking these steps can lead to more efficient operations.