-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In the world of electronics manufacturing, selecting the right equipment is crucial. A Reflow Oven is essential for achieving quality solder connections on circuit boards. Industry expert Dr. Emily Hudson once stated, “The efficiency of a Reflow Oven can make or break your production line.” This statement highlights the importance of choosing wisely.

Many factors influence the decision to buy a Reflow Oven. Brands, features, and price can overwhelm buyers. Understanding the specifications is vital. Small details in airflow and heating zones affect final outcomes. A poor choice can lead to failed products, which wastes time and resources.

Electronics manufacturing is an intricate field. Even slight miscalculations can result in significant issues. Buyers often overlook essential features while focusing solely on price. This can lead to regret later. Hence, careful consideration and research are needed to navigate this market effectively.

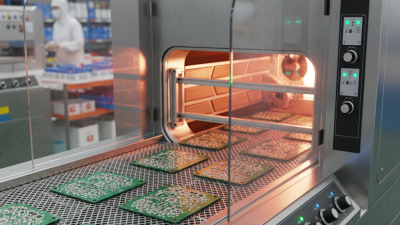

Reflow ovens play a critical role in electronics manufacturing.

These machines enable the soldering of surface-mounted components to printed circuit boards (PCBs) through a controlled heating process.

During the reflow soldering phase, a series of temperature zones are used to melt solder paste. This process requires precision and attention to detail.

Many manufacturers face challenges when using reflow ovens. For instance, inconsistent heat profiles can lead to defects in solder joints.

A poorly calibrated oven might not melt the solder evenly, which creates weak connections. Additionally, selecting the right temperature settings is vital;

too high or too low can result in component damage or poor electrical performance.

Understanding the importance of these ovens is essential. While they are often seen as a straightforward solution, the reality is more complex.

Operators must constantly monitor performance and be prepared to adjust settings based on real-time feedback.

This responsiveness is key to achieving reliable results in production.

Ideal performance is not achieved by chance; it requires practice and commitment to continuous improvement.

Choosing the right reflow oven is crucial for optimal electronics manufacturing. Key features must be considered for efficiency. Temperature control is vital. A precise temperature profile helps in reducing defects. Reports suggest that 85% of soldering issues arise from incorrect thermal profiles. A well-calibrated oven can drastically minimize these errors.

Another important factor is the size of the oven. Depending on your manufacturing scale, you may need a compact model or a larger one accommodating bigger boards. Many manufacturers fail to assess their production needs properly, leading to space issues or inefficiencies. An ideal oven should fit your workspace without being too compact or excessive.

Conveyor speed and adjustable zones are also crucial. These elements affect the flow and quality of the soldering process. Up to 40% of users find their solder joints lacking due to improper conveyor settings. Flexibility in adjusting these parameters allows for better optimization. It’s vital to analyze your existing processes to ensure that your reflow oven aligns with your production goals.

| Model | Temperature Range | Maximum PCB Size | Heating Zones | Warranty | Price Range |

|---|---|---|---|---|---|

| Model A | 150°C - 300°C | 18" x 24" | 8 | 2 Years | $5,000 - $7,000 |

| Model B | 140°C - 260°C | 20" x 24" | 6 | 1 Year | $4,000 - $6,000 |

| Model C | 150°C - 350°C | 24" x 30" | 10 | 3 Years | $6,500 - $9,500 |

| Model D | 160°C - 280°C | 20" x 20" | 8 | 2 Years | $5,500 - $8,000 |

| Model E | 120°C - 320°C | 22" x 22" | 9 | 1 Year | $4,500 - $7,500 |

When selecting a reflow oven, consider the specifications that matter most.

Temperature profiles should be adjustable.

This allows for better control over the soldering process. Look for models with a

range of heating zones. Different zones can provide consistent results

across various circuit board types.

An essential factor is the oven’s capacity. Ensure it fits your

production needs. Sometimes, a small oven might seem sufficient. Yet, it can become a bottleneck in

higher-volume production. Remember to evaluate the footprints of the ovens too. Space can be a constraint in many

production environments.

Tips: Invest in a model with

user-friendly controls. Complex settings can lead to mistakes.

Clear manuals aid in proper usage, too. Regular maintenance is crucial. Neglecting this can impact

performance and lead to unexpected breakdowns.

Researching user reviews can provide real-world insights. Take your time; the

right choice will enhance your

production efficiency.

Reflow ovens play a crucial role in electronics manufacturing. They use heat to melt solder and establish connections between components. Different technologies provide varied advantages. Understanding these can affect production quality and efficiency.

Infrared reflow ovens utilize infrared lamps. They heat quickly and offer precise temperature control. This method can be beneficial for smaller batches. However, it might not be as effective for larger production runs. Airflow reflow ovens, on the other hand, use hot air circulation. This provides thorough heating for all components. While effective, they can have slower heating times compared to infrared options.

Tips: Always evaluate your production scale. Smaller projects might benefit from infrared. Larger productions might need airflow ovens. Moreover, consider energy efficiency. Some ovens consume a lot of power, impacting overall costs. The choice of technology can make or break your manufacturing process. Reflect on your specific needs and budget before deciding.

This chart compares different performance metrics of various reflow oven technologies in the year 2026. The data reflects the average temperature uniformity, energy efficiency, and production speed of these ovens.

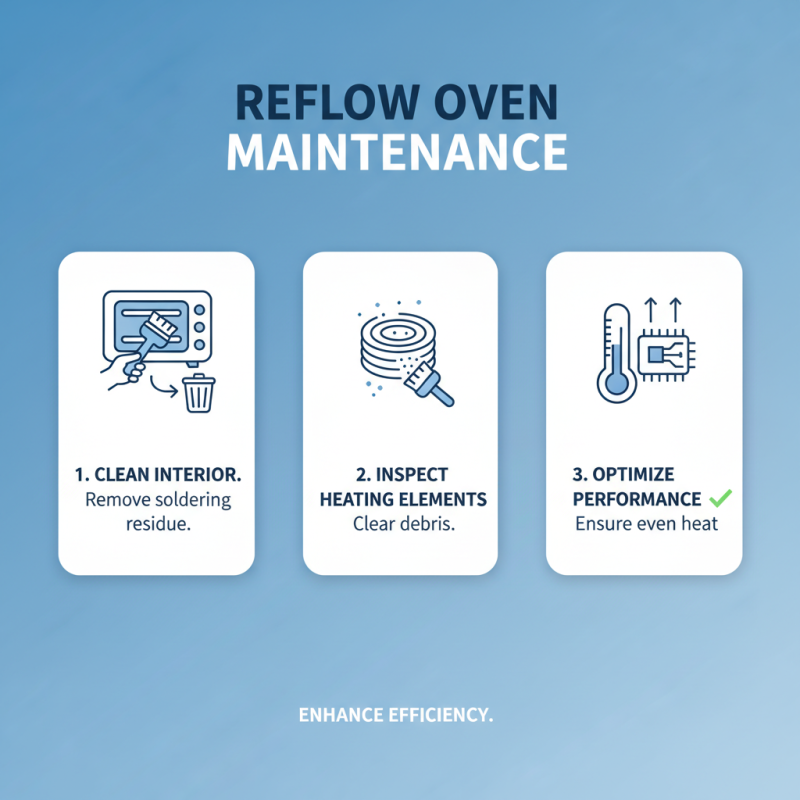

Maintaining a reflow oven is crucial for optimal performance in electronics manufacturing. Keeping the interior clean can significantly enhance efficiency. Residue from past soldering can affect heat distribution. Regularly inspect the heating elements and ensure they are free from debris. A simple brush can make a difference.

Calibration is another key aspect of maintenance. Temperature accuracy ensures components are soldered correctly. Using an infrared thermometer can help monitor heat zones. Adjustments may be necessary over time. Also, consider the profile settings. They might need fine-tuning based on the materials used.

Best practices include training staff on proper usage. This reduces errors and extends equipment life. Regularly review operating manuals for updates. Engaging with the team about challenges can lead to better solutions. Remember, even small adjustments can have a significant impact on production quality.