-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In the rapidly evolving electronics industry, the significance of a BGA Rework Station cannot be overstated, especially when it comes to PCB repair and upgrade processes. According to a recent industry report by IPC, the global PCB market is projected to grow by 4.5% annually, emphasizing the increasing demand for reliable repair technologies. The ability to efficiently rework Ball Grid Array (BGA) components is crucial, as these components are widely used in modern electronic devices due to their high pin count and excellent performance. Utilizing a BGA Rework Station not only enhances the quality of repairs but also significantly reduces turnaround times and operational costs. As manufacturers and repair service providers seek to meet this growing demand, understanding the importance of investing in advanced BGA rework technology becomes essential for maintaining competitive advantage in the market.

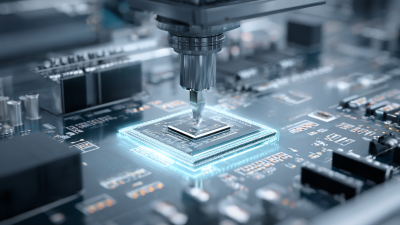

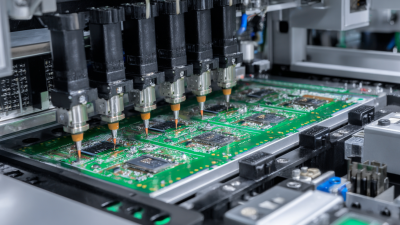

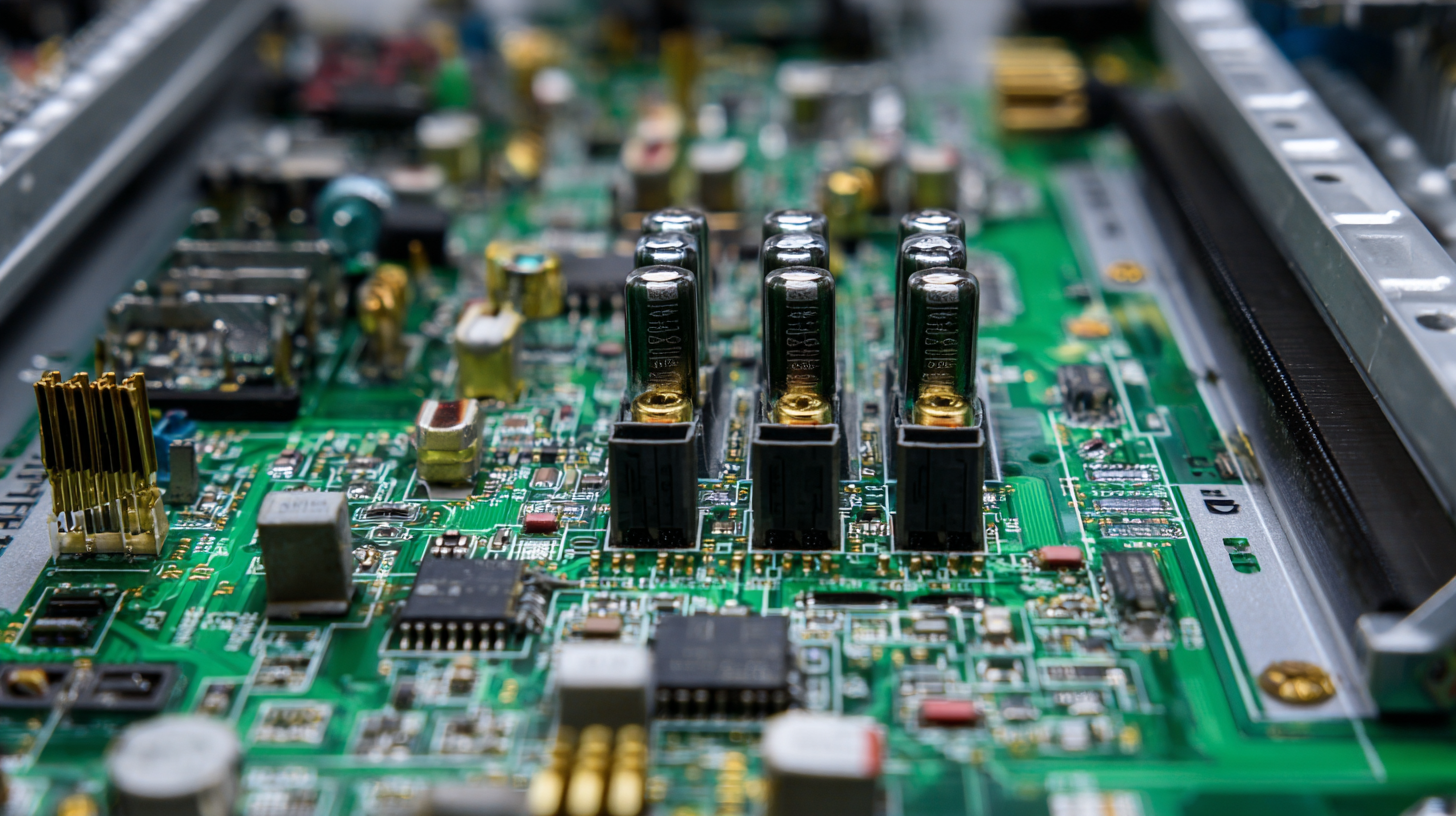

BGA rework stations play a crucial role in modern PCB maintenance, particularly when it comes to servicing and upgrading printed circuit boards. These specialized tools allow technicians to efficiently rework Ball Grid Array (BGA) components, which are commonly found in advanced electronic devices. The ability to precisely apply heat and control temperature is vital in ensuring that these delicate components are not damaged during the repair process. With ongoing innovations in surface mount technology (SMT), these rework stations are becoming even more sophisticated, integrating features such as advanced temperature profiles and enhanced reliability.

When utilizing a BGA rework station, remember these tips: First, always ensure that your soldering iron and rework station are set to the correct temperature for the specific components being worked on. Second, use quality soldering materials to reduce the likelihood of defects during repairs. Lastly, practice proper handling techniques to maintain the integrity of the PCB and its components. As the demand for efficient electronic repairs grows, the role of BGA rework stations will continue to evolve, making them indispensable for technicians in the field.

This chart illustrates the performance metrics of BGA rework stations, highlighting their success rate, time efficiency, cost reduction, and error rates in PCB maintenance processes.

When assessing the efficacy of a BGA rework station for PCB repair and upgrade, there are several key features that should not be overlooked. Firstly, the station should have precise temperature control capabilities. According to a study by IPC, maintaining optimal soldering temperatures is critical, with a deviation of just a few degrees potentially leading to component damage or insufficient solder joints. An effective BGA rework station should therefore offer a range of temperature settings that can be adjusted to the specific requirements of different components.

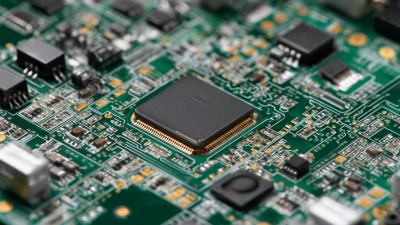

Another vital feature is the station's vacuum capability, which allows for the effective removal and placement of BGAs without causing damage to surrounding components. A recent report from the Electronics Industry Association highlighted that up to 30% of rework failures stem from improper handling during the desoldering and soldering process. Look for stations equipped with advanced vacuum systems that enhance precision and reduce the risk of errors. Moreover, features such as a built-in camera for alignment assistance can significantly streamline the rework process, as visual aids are proven to improve accuracy in component placement by up to 20%, according to a report from the International Journal of Electronics Manufacturing. These considerations make a significant impact on the overall success of PCB repair and upgrade initiatives.

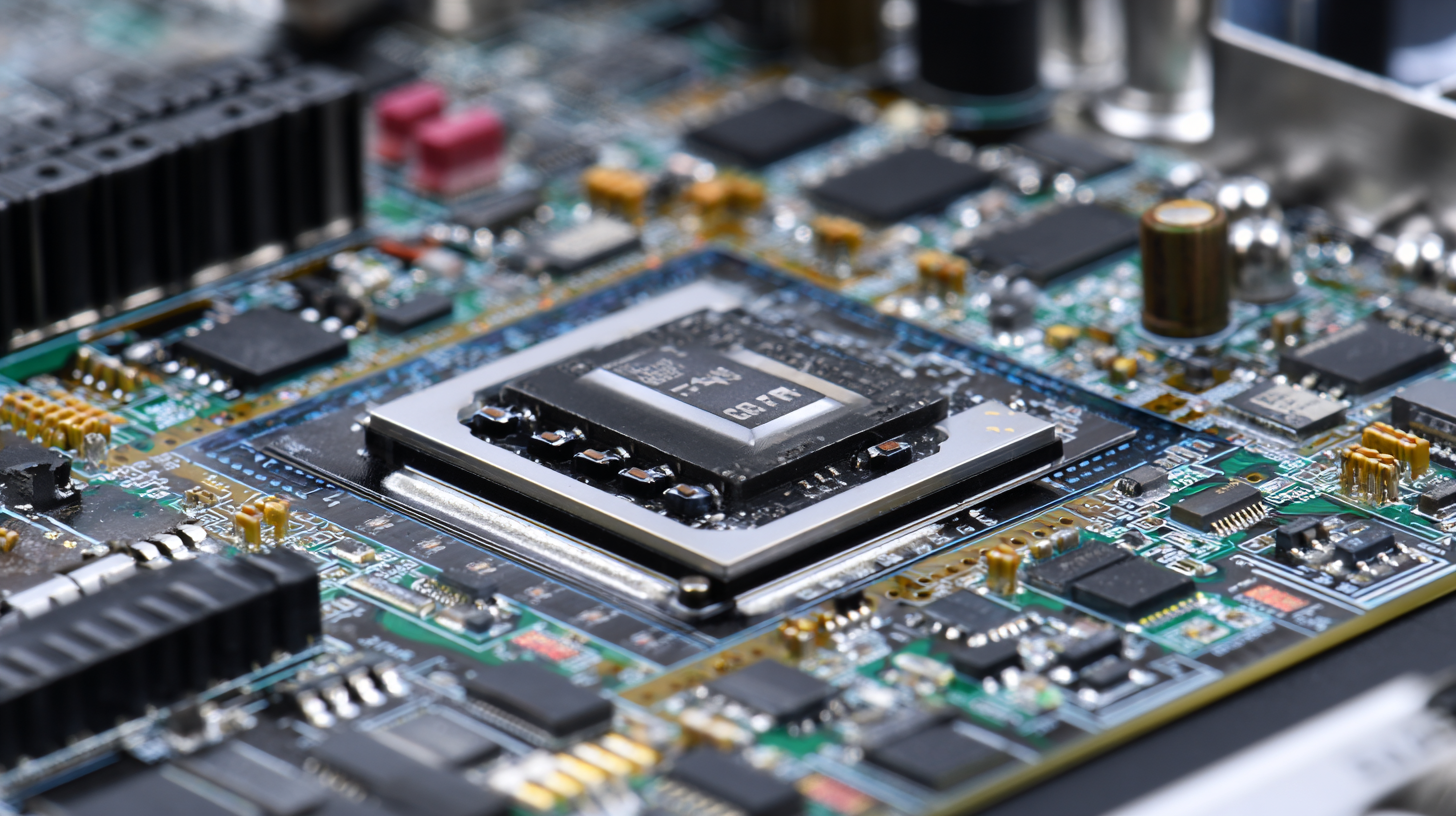

BGA (Ball Grid Array) rework is a critical process in PCB (Printed Circuit Board) repair and upgrade, especially given the increasing complexity of electronic devices. According to industry reports, BGA packages account for 40% of all IC packages in use today, reflecting the need for specialized repair methods. The rework process involves several precise steps, ensuring the integrity of the PCB while replacing or upgrading components.

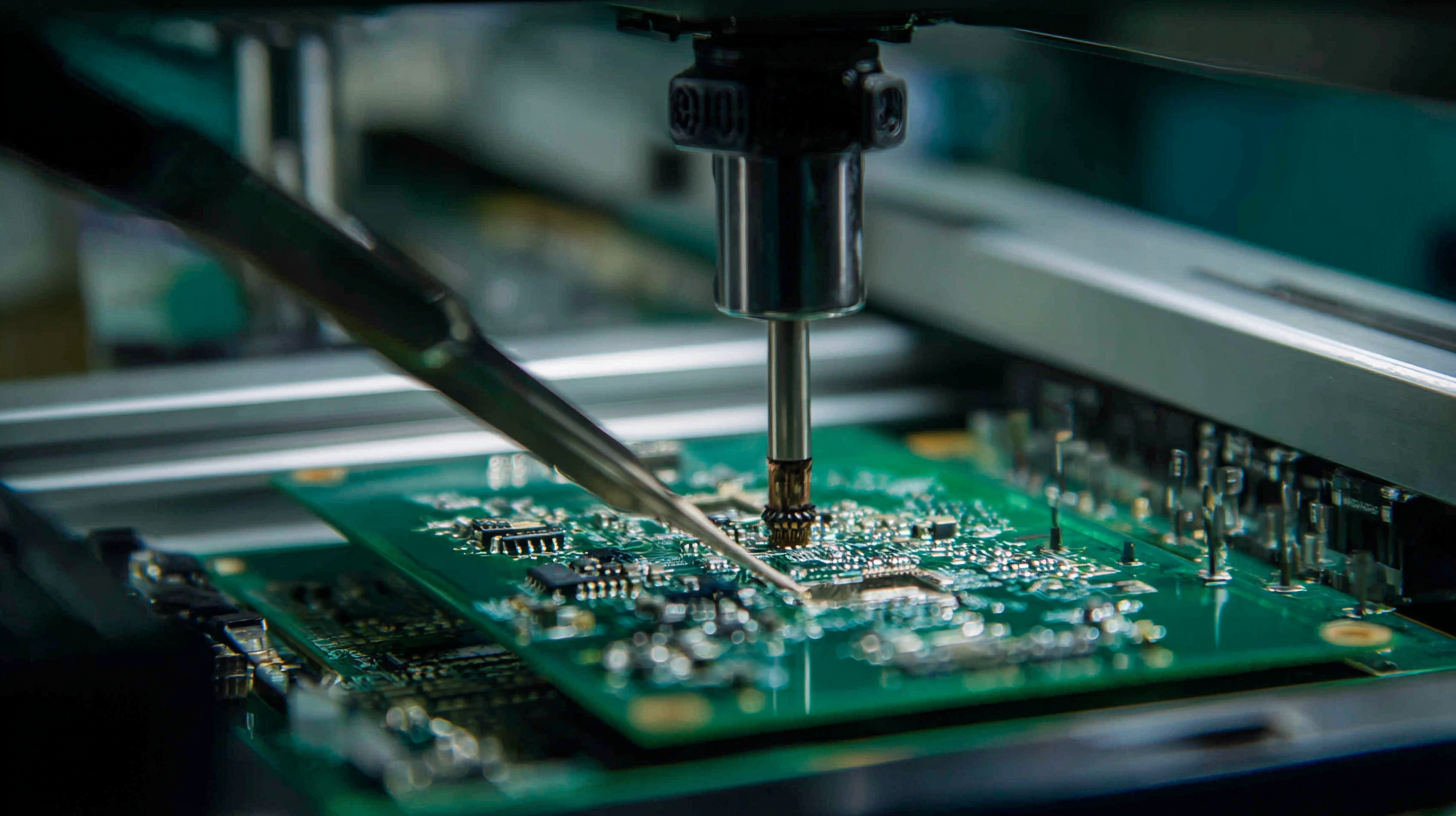

The first step in the BGA rework process is the careful removal of the defective BGA component. This requires a properly calibrated hot air rework station to evenly heat the solder balls beneath the component. Once the old part is removed, the PCB must be inspected for any damage. Following inspection, new solder paste is applied to the pads where the BGA will be placed. Next, the new BGA component is aligned and positioned correctly over the pads to prevent misalignment. After achieving accurate placement, the BGA is reflowed using a rework station, which melts the solder and creates strong connections between the component and the board, ultimately ensuring reliability.

Data from recent market analyses indicates that effective handling of BGA components can improve yield rates in PCB repairs significantly, with some facilities reporting success rates of up to 95% when using advanced rework techniques. This underscores the importance of investing in high-quality BGA rework stations and training personnel in proper techniques, facilitating not just repairs but also upgrades of existing boards to meet new technological demands.

| Repair Stage | Description | Tools Required | Estimated Time |

|---|---|---|---|

| Diagnosis | Identifying the issue with the PCB and BGA component. | Multimeter, Oscilloscope | 1-2 hours |

| Preparation | Gathering tools and preparing the rework station. | BGA Rework Station, Soldering Iron | 30 minutes |

| Desoldering | Removing the defective BGA component from the PCB. | Hot Air Station, BGA Nozzle | 1 hour |

| Cleaning | Cleaning the pads to ensure proper adhesion of the new BGA. | Solder Wick, Isopropyl Alcohol | 30 minutes |

| Reballing | Reballing the BGA component before placement. | BGA Reballing Kit | 1 hour |

| Resoldering | Placing the new or reworked BGA onto the PCB and soldering. | BGA Rework Station, Solder Paste | 1 hour |

| Verification | Testing the PCB to ensure proper functionality. | Multimeter, Functional Tester | 1-2 hours |

In the world of PCB repair and upgrade, BGA (Ball Grid Array) rework presents its own set of challenges. One of the most common issues is the alignment of the BGA components during soldering.

Misalignment can lead to poor electrical connections or even short circuits. To mitigate this, it's essential to use high-precision alignment tools and ensure that the PCB surface is clean before starting the rework process.

In the world of PCB repair and upgrade, BGA (Ball Grid Array) rework presents its own set of challenges. One of the most common issues is the alignment of the BGA components during soldering.

Misalignment can lead to poor electrical connections or even short circuits. To mitigate this, it's essential to use high-precision alignment tools and ensure that the PCB surface is clean before starting the rework process.

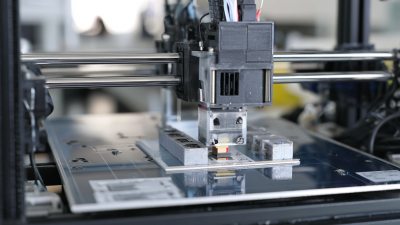

Another challenge often encountered is temperature management. BGA components require specific heating profiles to avoid thermal stress, which can crack the solder balls or the PCB itself. Deploying a reliable rework station with programmable temperature profiles can significantly enhance results.

Tips: Always preheat the PCB to minimize thermal shock and use infrared sensors to monitor temperature accurately during the rework process. Additionally, invest in quality solder paste that is compatible with BGA types to ensure a better bond and reliability. Proper training on using the rework station will also help technicians avoid common pitfalls in the rework procedures.

The BGA rework station plays a critical role in the efficient repair and upgrade of printed circuit boards (PCBs), particularly in the context of Ball Grid Array (BGA) components. According to a report by IPC—Association Connecting Electronics Industries, the market for PCB repair and rework solutions is projected to grow by 5.5% annually through 2025. This growth underscores the increasing reliance on sophisticated rework technologies like those provided by BGA stations, which allow for precise re-soldering and replacement without the need for complete PCB replacement, thus saving cost and time.

Best practices for upgrading PCBs using BGA rework technology include ensuring temperature control during the rework process. A study by the International Journal of Electronics Manufacturing highlighted that improper thermal profiles can lead to component failure or damage. Technicians should also utilize appropriate flux materials and maintain equipment regularly to enhance the quality of soldering. Additionally, organizations should invest in training their staff on the latest rework techniques to ensure that upgrades are performed efficiently and with minimal defects. These practices not only improve the repair success rate but also extend the lifecycle of electronic devices, aligning with the industry’s push towards sustainability.