-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

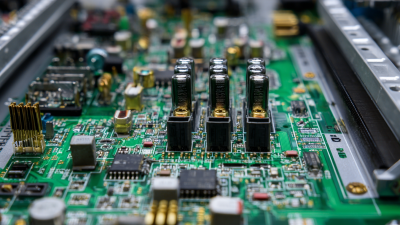

When it comes to repairing printed circuit boards (PCBs), selecting the right BGA rework station is crucial for achieving optimal results. A BGA (Ball Grid Array) rework station is designed to facilitate the delicate process of soldering and desoldering ball grid array components, which are common in modern electronics. With a multitude of options available on the market, understanding the key features and specifications of a BGA rework station can significantly impact the efficiency and quality of your PCB repair efforts.

In this guide, we will explore the essential factors to consider when choosing the best BGA rework station tailored to your specific repair needs. From temperature control and heating methods to the size and compatibility of the station with different PCB layouts, each element plays a vital role in ensuring successful component rework. Additionally, we will highlight the importance of user-friendly interfaces and safety features, which can streamline the repair process while minimizing the risk of damage to sensitive components.

Ultimately, by understanding your requirements and the capabilities of various BGA rework stations, you can make an informed decision that enhances your PCB repair capabilities and sets the foundation for achieving high-quality electronic repairs.

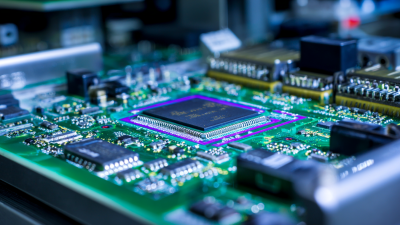

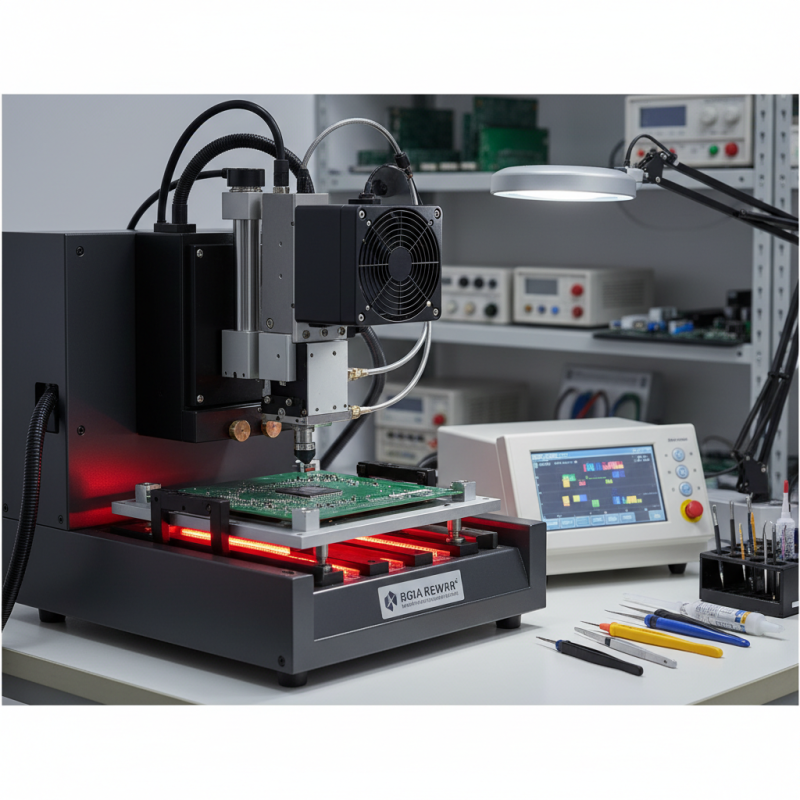

When selecting a BGA rework station for PCB repairs, it's crucial to understand the key features that can significantly affect performance and efficiency. One of the primary considerations is temperature control. A high-quality rework station should offer precise temperature settings, allowing operators to tailor the heat applied to different components without risking damage. Look for options that feature dual-zone heating for both the PCB and the component, ensuring even heat distribution and minimizing thermal stress.

Another important aspect is the size and capability of the station. Depending on your specific repair requirements, you may need a larger work area that accommodates various PCB sizes and complex layouts. Additionally, check whether the station supports various types of rework process—such as soldering, desoldering, and alignment—giving you versatility for multiple projects. User-friendly interfaces and robust suction systems for component removal are also valuable features to consider, as they enhance the overall ease of use and effectiveness of the rework station.

When selecting a BGA rework station for your PCB repair needs, it is essential to first assess the specific requirements of your projects. Understanding the types of PCBs you will be working with, such as single-layer or multi-layer boards, can help narrow down the features you need. Consider the size and complexity of the components on your boards; more sophisticated BGA packages might require advanced rework capabilities. Evaluate whether your operations will benefit from a station that offers precise temperature control, vacuum soldering, or the ability to handle multiple BGA sizes.

Additionally, consider your repair environment and the expected volume of work. If you're in a high-production setting, a rework station with faster heating and cooling cycles could increase efficiency. Look into the ease of use and ergonomics of the station, as this can significantly impact productivity, especially during long repair sessions. Lastly, assess the availability of spare parts and technical support for the station to ensure that you have reliable resources at hand for maintenance and troubleshooting. By clearly identifying your PCB repair needs, you can choose a rework station that best fits your operational style and enhances your workflow.

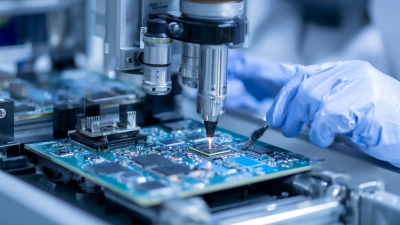

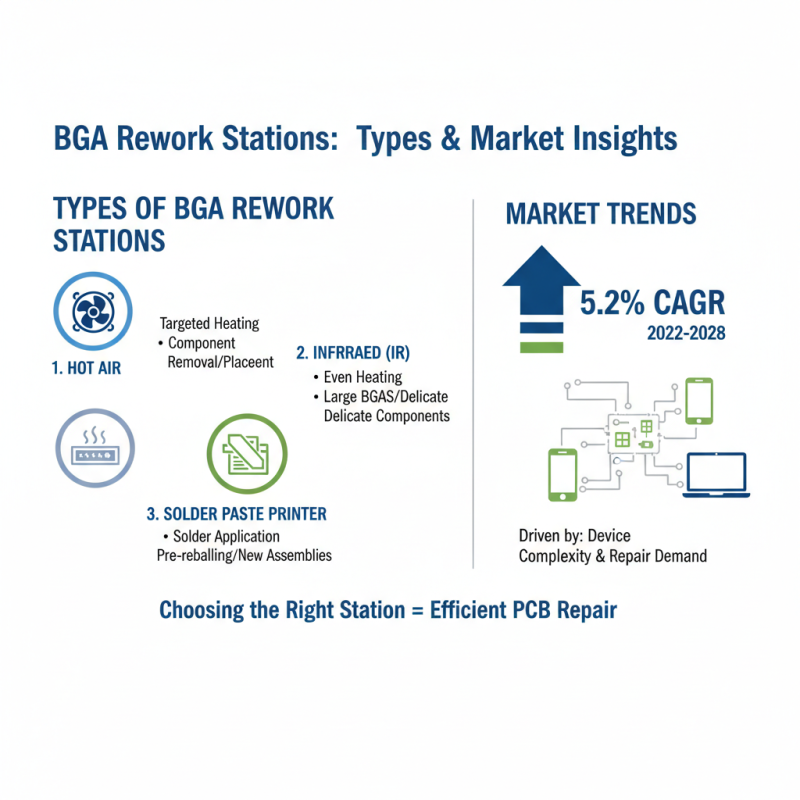

When selecting a BGA rework station for PCB repair, it's essential to evaluate the different types available in the market. According to industry reports, the global BGA rework station market is projected to grow at a CAGR of 5.2% from 2022 to 2028, largely driven by the increasing complexity of electronic devices and the demand for efficient repair solutions. The three main types of BGA rework stations are hot air rework, infrared rework, and solder/paste printer systems, each offering distinct advantages depending on the specific repair requirements.

Hot air rework stations are popular for their versatility and ease of use. They utilize heated air to uniformly melt solder, allowing for the precise removal and replacement of BGA components. This method is ideal for smaller boards and repairs requiring minimal thermal impact. Meanwhile, infrared rework stations use focused infrared radiation to heat the board and components, providing a controlled temperature profile that minimizes the risk of damaging surrounding parts. Research indicates that while infrared systems may require a more significant upfront investment, their efficiency and ability to maintain consistent temperatures can lead to reduced repair times and improved quality control.

Moreover, the choice of station can be influenced by the scale of operations. For high-volume production environments, automated solder/paste printers may be a worthwhile consideration, as they streamline the assembly process and enhance throughput. According to a report from a leading market analysis firm, nearly 40% of production facilities have integrated automated solutions to optimize their PCB rework processes. As technology continues to evolve, understanding the different types of BGA rework stations and their operational benefits will be crucial for achieving quality repairs and maintaining competitive advantage in the electronics industry.

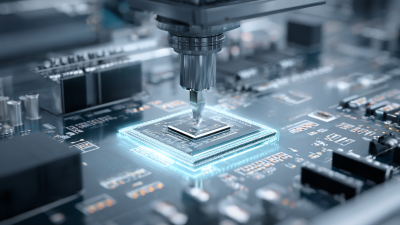

When selecting the right tools and accessories for a BGA rework station, it's important to consider the specific requirements of your PCB repair projects. According to a recent industry report, the demand for BGA rework stations is expected to grow by approximately 5.6% annually through 2025, highlighting the importance of investing in quality components. When evaluating options, look for features such as adjustable temperature control, efficient heating technology, and a reliable vacuum pickup system, as these factors can significantly influence the ease and effectiveness of your rework tasks.

Additionally, consider the compatibility of the tools with various BGAs and the size of your PCBs. A comprehensive selection of nozzles and tips, designed for different BGA configurations, will enhance precision and minimize the risk of damage to surrounding components. It's essential to also assess the availability of replacement parts and support for your chosen equipment. A recent survey indicated that effective rework setups can reduce repair times by up to 30%, demonstrating the impact of having the right tools readily available. Investing time in selecting the appropriate accessories not only improves the quality of repairs but also boosts overall productivity in PCB manufacturing and maintenance processes.

When selecting a BGA rework station, budgeting is a critical factor that can significantly influence your decision. To determine the cost-effectiveness of your choice, start by defining your specific repair needs and the volume of work you expect. Different stations come with varying features, and understanding which capabilities are essential for your operations can help you avoid overspending on unnecessary functionalities. A thorough assessment of your requirements will serve as a foundation for making a more informed financial decision.

Additionally, consider the long-term costs associated with the station. Initial expenditures are important, but the cost of parts, maintenance, and training can accumulate over time. Investing in a more efficient rework station may mitigate repair time and improve overall productivity, ultimately leading to cost savings. Analyzing the total cost of ownership will provide a clearer picture of the value each option offers. By weighing these factors against your budget, you can select a BGA rework station that not only fits your immediate financial constraints but also supports sustainable growth in your PCB repair endeavors.