-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In the ever-evolving landscape of electronics manufacturing, choosing the right equipment is crucial for optimizing production efficiency and ensuring product quality. Among the most respected brands in the surface mount technology (SMT) field is Fuji, renowned for its innovative SMT machines that cater to a diverse range of manufacturing needs. According to a recent industry report by Smithers Pira, the global SMT equipment market is projected to grow at a compound annual growth rate (CAGR) of 6.5% through 2025, underscoring the increasing demand for efficient fabrication processes.

Selecting the best Fuji SMT machine is not merely a matter of preference; it is a strategic decision that can significantly impact operational performance and cost-effectiveness. With various models designed for different production scales and types, it is essential for manufacturers to assess their specific requirements and workflow processes. The right Fuji SMT machine can streamline assembly lines, reduce downtime, and enhance the overall quality of electronics, contributing to long-term competitiveness in the marketplace. As the industry shifts towards more automated and precise production methods, understanding the advantages and functionalities of Fuji SMT machines becomes imperative for manufacturers looking to stay ahead.

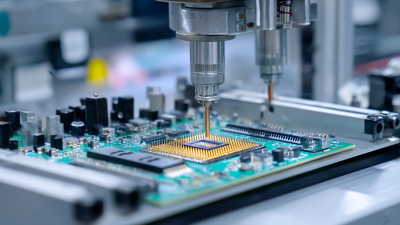

When selecting a Fuji SMT machine for your manufacturing operations, understanding the various types and their specific applications is crucial. There are several categories of Fuji SMT machines, including modular systems that offer flexibility for assembly line configurations, and high-speed machines designed for mass production. Each type has distinct benefits, with modular systems allowing for easy upgrades and adjustments based on product changes, while high-speed machines prioritize efficiency for large-scale outputs.

The adaptability of these machines is further enhanced by the incorporation of advanced technologies. The integration of IoT solutions enables real-time monitoring and data analytics, facilitating predictive maintenance and optimizing production processes. This technological advancement allows manufacturers to streamline operations and minimize downtime, making it easier to track inventory and manage workflow effectively. Understanding these machine types and their capabilities will empower businesses to make informed decisions that align with their production needs and objectives.

Choosing the right Fuji SMT machine for your manufacturing needs involves considering several key features that can significantly impact your production efficiency and quality. One of the primary factors is the machine's speed and throughput. Assessing the number of components it can handle per hour is crucial; a higher throughput can lead to improved productivity. Additionally, look for machines that offer flexibility in handling various PCB sizes and types, which can enhance your production versatility.

Another important feature to evaluate is the ease of programming and setup. Machines that come with user-friendly interfaces and advanced software for programming can reduce downtime during changeovers. These features enable operators to quickly adapt to different production runs, maintaining efficiency without compromising quality.

**Tips:** When selecting a Fuji SMT machine, consider conducting a thorough evaluation of your specific production needs and future scalability. It's also beneficial to seek demonstrations or trials to ensure the machine meets your operational requirements. Finally, consulting with industry professionals or peers who have hands-on experience with Fuji machines can provide valuable insights that aid in making an informed decision.

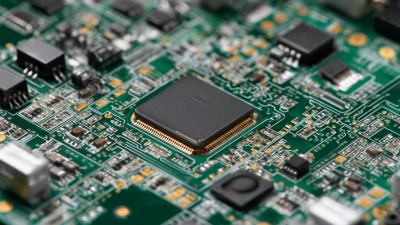

When selecting the best Fuji SMT machine for your manufacturing needs, it's essential to conduct a comparative analysis of the different Fuji SMT models available in the market. Fuji offers a range of models, including the NXT II and the AIMEX series, each designed to cater to specific production requirements and environments. According to a report by IPC, manufacturers have noted that using advanced pick-and-place technology can increase placement accuracy by up to 30%, directly impacting yield and reducing rework costs.

The Fuji NXT II, for example, is known for its high-speed capabilities and versatility, suitable for high-mix, low-volume production environments. It boasts a placement speed of up to 100,000 components per hour, making it an ideal choice for businesses that require efficiency without compromising quality. Conversely, the AIMEX series is tailored for high-volume manufacturing, providing flexibility with a larger range of component sizes. A recent analysis by Research and Markets indicated that investment in high-efficiency SMT machines like those from Fuji could lead to a reduction in operational costs by approximately 15% over three years, reinforcing the importance of choosing the right model based on production scale and objectives.

| Model | Placement Speed (Cph) | Component Range (mm) | Board Size (Max)(mm) | Footprint (m2) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 3000 | 0201 - 50mm | 500 x 500 | 2.5 | 150,000 |

| Model B | 2500 | 0402 - 60mm | 600 x 600 | 3.0 | 120,000 |

| Model C | 3500 | 0201 - 70mm | 700 x 700 | 3.5 | 200,000 |

| Model D | 2800 | 0603 - 80mm | 800 x 800 | 4.0 | 175,000 |

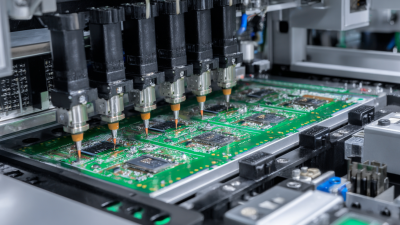

When selecting the best Fuji SMT machine for your manufacturing needs, assessing production volume and flexibility is crucial. According to a report by IPC, the global electronics manufacturing services market is projected to exceed $1 trillion by 2025, emphasizing the increasing demand for efficient and adaptable manufacturing solutions. Companies must consider their current and future production volumes to ensure the Fuji SMT machine they choose can handle their specific throughput requirements. For instance, machines equipped with advanced features such as high-speed pick-and-place technology can significantly enhance production rates, catering to both high-volume runs and smaller batch orders.

Moreover, flexibility in manufacturing processes allows companies to adapt quickly to market changes or customer needs. A study from the Association for Manufacturing Technology indicates that 60% of manufacturers prioritize versatility in their equipment selection. Fuji SMT machines are designed with modular capabilities, enabling quick changeovers between different product designs. This feature is particularly beneficial in industries where product life cycles are short, as it allows manufacturers to remain competitive by reducing downtime and responding swiftly to new demands. By focusing on these elements of production volume and flexibility, manufacturers can optimize their operations and achieve more efficient and profitable outcomes.

When selecting a Fuji SMT machine for your manufacturing needs, one of the paramount aspects to consider is cost. The investment in a high-quality SMT machine can range greatly, with entry-level machines starting around $50,000, while high-end models equipped with advanced features can exceed $250,000. According to a market analysis by IPC, the global SMT equipment market is projected to grow at a compound annual growth rate (CAGR) of 5.3% over the next five years, emphasizing the increasing demand for efficient and reliable machines in the electronics manufacturing sector.

Budgeting effectively involves looking beyond the initial purchase price. Maintenance costs, spare parts accessibility, and operational efficiency also play crucial roles in total cost ownership. A report from ResearchAndMarkets suggests that manufacturers can save up to 20% in operational costs by investing in machines with better energy efficiency standards and lower downtime rates. Therefore, when determining your budget, consider not just the purchase cost but the long-term financial implications and overall return on investment that a Fuji SMT machine can provide.