-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

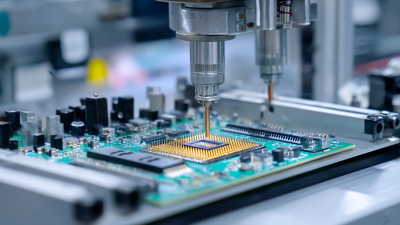

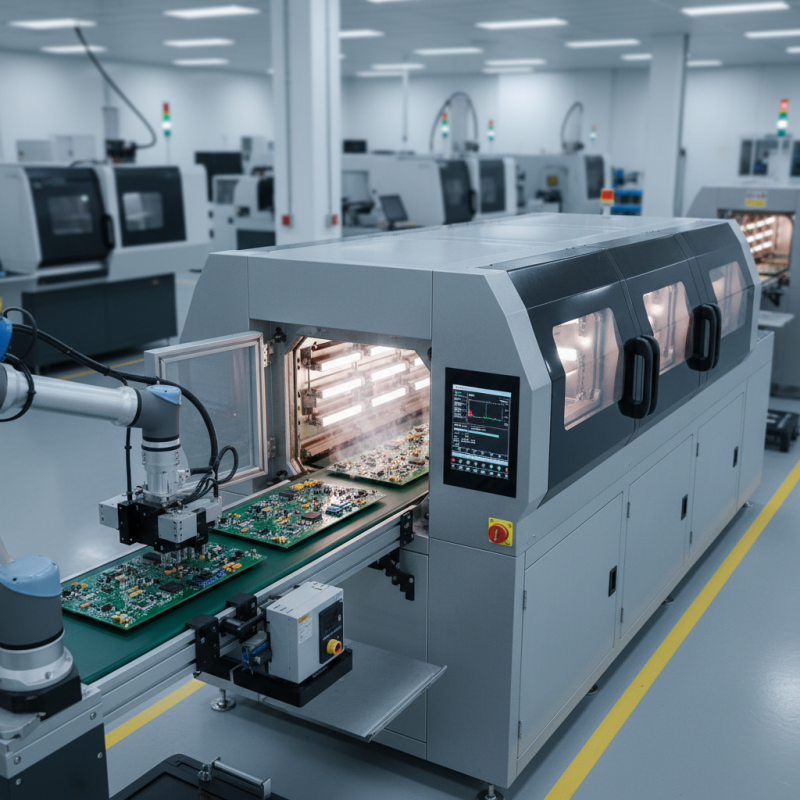

As the demand for high-quality and efficient electronics manufacturing continues to rise, selecting the right SMD reflow oven is critical for PCB assembly. According to a report by MarketsandMarkets, the global soldering equipment market is projected to reach USD 9.53 billion by 2025, indicating a robust growth driven by advancements in technology and increased production requirements. Reflow ovens are essential tools in this process, as they ensure precise temperature control and uniform heat distribution, essential for achieving optimal solder connections and minimizing defects.

Furthermore, the IPC's annual PCB Market Report highlights that the increasing complexity of electronic designs, combined with the miniaturization of components, is significantly influencing the choice of reflow ovens. Manufacturers must consider various factors such as oven design, heating profiles, and automation capabilities when selecting a suitable SMD reflow oven for their specific assembly needs. Understanding these critical aspects will not only enhance manufacturing efficiency but also improve product reliability, which is paramount in the highly competitive electronics market.

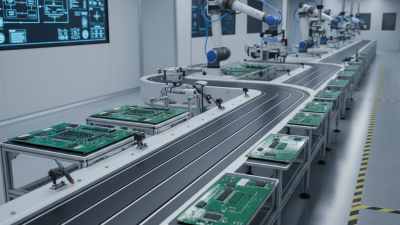

When selecting the best SMD reflow oven for your PCB assembly needs, there are several critical factors to consider to ensure optimal performance and efficiency. One of the foremost considerations is the oven's size and capacity. Assessing the dimensions of your PCB assemblies and the volume of production required will guide you in choosing an oven that can accommodate your tasks without overcrowding or inefficiencies.

Another significant aspect is the heating profile capability of the reflow oven. Different components and solder types require varying temperature profiles for effective soldering. Therefore, it is crucial to opt for an oven that offers programmable temperature zones. This feature allows for precise control over heating elements, ensuring uniform temperature distribution throughout the PCB. Additionally, flexibility in adjusting settings can cater to future changes in component specifications or soldering techniques.

Lastly, consider the energy efficiency and overall cost of operation of the oven. Energy-efficient models can lead to reduced operational costs over time, which is particularly beneficial for high-volume manufacturers. Furthermore, ease of maintenance and available support services are also vital; an oven that is easier to maintain will minimize downtime and enhance overall productivity in your assembly line.

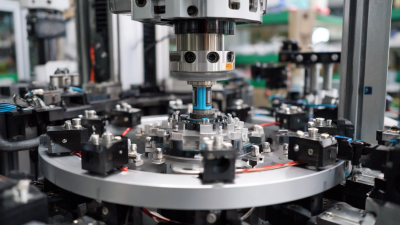

When it comes to selecting the right SMD reflow oven for your PCB assembly needs, understanding the types of ovens available on the market is crucial. The most common types include:

When selecting the best SMD reflow oven for your PCB assembly needs, it is essential to focus on several key features that contribute to both the efficiency and the quality of your production process. One crucial aspect is temperature uniformity, which directly impacts solder joint reliability. According to a report by IPC, a leading global association in the electronics industry, approximately 30% of PCB failures are linked to inadequate temperature profiles during soldering. A high-quality reflow oven should maintain a uniform temperature across the entire PCB surface, ensuring even heating and reducing the likelihood of cold solder joints or component damage.

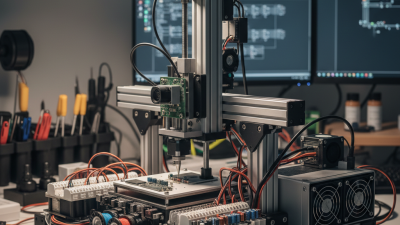

Another significant feature is the oven's profile flexibility. The ability to customize thermal profiles is vital, as different components and solder paste formulations require specific heating settings to achieve optimal results. A study published by the Surface Mount Technology Association (SMTA) highlights that manufacturers who utilize ovens with programmable profiles see an increase in first-pass yield rates by up to 15%. This adaptability not only enhances soldering quality but also allows for accommodating various PCB designs and assembly requirements, making the reflow oven a more versatile investment.

Lastly, consider the overall energy efficiency of the oven. As sustainability becomes a priority in manufacturing, energy-efficient reflow ovens can significantly reduce operational costs and environmental impact. The Department of Energy reports that advancing to more efficient heating technologies, such as conduction or convection, can cut energy consumption by as much as 25%. When evaluating options, prioritize ovens that leverage these newer technologies to achieve both cost savings and a lower carbon footprint while maintaining high-quality assembly outcomes.

| Feature | Importance | Recommended Specification |

|---|---|---|

| Temperature Profiles | Critical for soldering quality | Multi-zone control, ability to save multiple profiles |

| Heating Capacity | Ensures efficiency for larger boards | High output power (at least 3 kW) |

| Size and Dimensions | Fits workspace and board sizes | Variable sizes to accommodate different PCB dimensions |

| Energy Efficiency | Reduces operational costs | Class A energy rating |

| User Interface | Ease of operation | Touchscreen, intuitive controls |

| Maintenance and Support | Minimizes downtime | Accessible parts and responsive customer service |

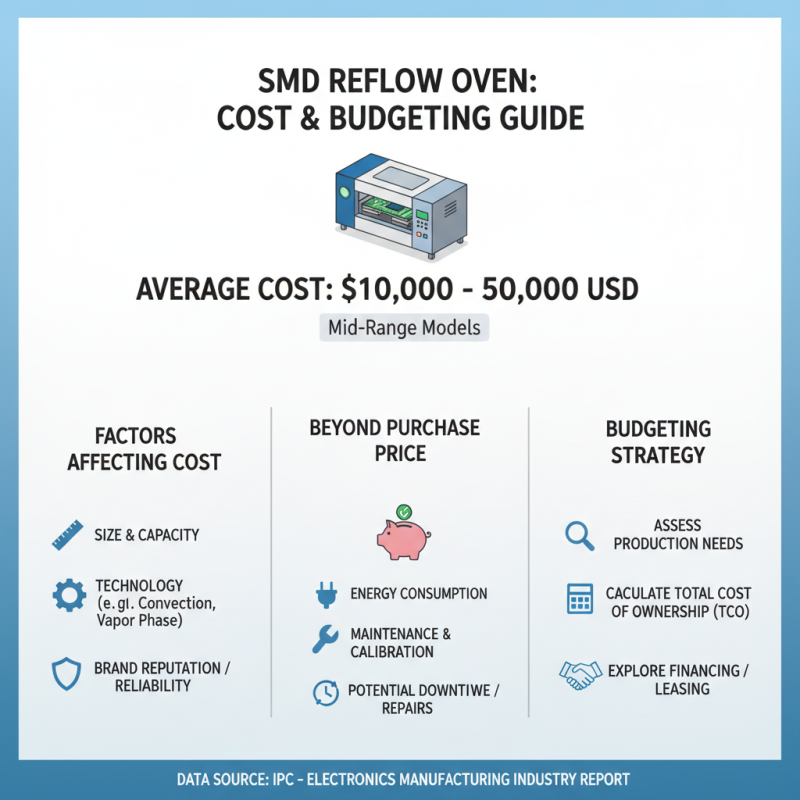

When considering the purchase of a surface mount device (SMD) reflow oven for PCB assembly, cost considerations and budgeting are paramount. According to a recent report by IPC, the leading trade association for the electronics manufacturing industry, the average cost of a mid-range reflow oven can vary significantly, typically ranging from $10,000 to $50,000 depending on features such as size, technology, and brand reputation. Understanding your budget is crucial, as it not only affects the type of oven you can afford but also the long-term operational costs which include energy consumption, maintenance, and potential downtime during repairs.

In addition to the initial purchase price, it's essential to factor in the total cost of ownership (TCO) for your reflow oven. Industry reports indicate that over 60% of the total lifecycle cost of a reflow oven comes from operational expenses rather than the upfront costs. This includes the costs associated with electricity consumption, which can be significant given that reflow ovens operate at high temperatures for extended periods. Moreover, investing in energy-efficient models can yield substantial savings over time. When budgeting, consider potential training costs for operators as well, ensuring they are well-versed in the equipment to minimize errors and maximize production efficiency. Balancing upfront investment with operational efficiency is key to making the best choice for your PCB assembly needs.

When investing in a high-quality SMD reflow oven for your PCB assembly needs, it's crucial to prioritize the maintenance and support aspects to ensure the longevity of this essential equipment. Regular maintenance not only extends the lifespan of the oven but also enhances its efficiency and reliability. Establishing a routine inspection schedule can help identify potential issues before they escalate, avoiding costly downtimes and repairs.

Tips: Always clean the components of your reflow oven, including the heating elements and conveyor belts, after each use. Accumulated residue can significantly affect the oven's performance and lead to uneven heating. Additionally, keep the equipment free from dust and debris by utilizing proper covers and storage solutions when the oven is not in use.

Moreover, having access to reliable technical support is vital. It’s advisable to choose a manufacturer or supplier that offers responsive customer service and technical assistance. This ensures that any malfunction or question regarding the equipment can be resolved promptly, allowing you to maintain production schedules with minimal interruptions. Regularly updating the oven’s software and firmware will further enhance functionality, ensuring optimal performance for your PCB assembly processes.