-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

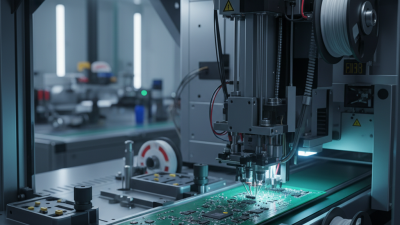

Choosing the right Smd Stencil Printer is crucial for efficiency in PCB manufacturing. The global PCB market is expected to reach $85 billion by 2025, highlighting the importance of precision equipment. A high-quality stencil printer can enhance production speed and accuracy, impacting the bottom line directly.

Many businesses overlook certain factors when selecting equipment. For instance, the printer's compatibility with different stencil materials can significantly affect the printing process. Reports indicate that 30% of companies struggle with improper stencil alignment, leading to costly errors. Investing in the right printer can mitigate these issues.

As technology evolves, the demands on Smd Stencil Printers increase. User feedback is essential for refining choices. Inadequate research can result in poor equipment selection. Balancing cost with functionality is not easy. Therefore, businesses must reflect on their specific needs before making a decision.

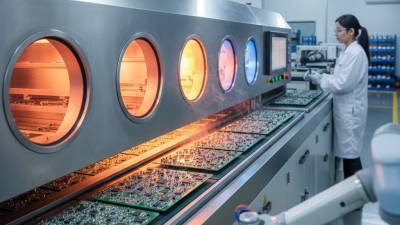

SMD stencil printers are crucial for anyone involved in electronics manufacturing. They apply solder paste accurately onto printed circuit boards (PCBs). Various types exist, catering to diverse applications. Manual stencil printers are ideal for smaller operations. They allow operators to control the paste application closely. However, they require skill and practice.

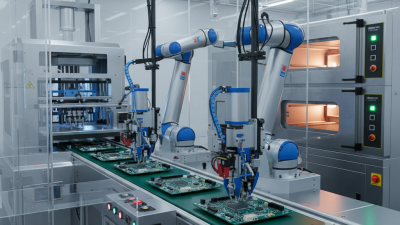

Automatic stencil printers offer speed and efficiency. They handle larger volumes and can reduce human error. However, they can be complex to set up. For some users, the initial learning curve may be steep. Semi-automatic printers strike a balance between manual and automatic. They still need human intervention but streamline some processes.

When choosing a printer, consider your needs. Think about the size of your production run. Are you working on prototypes or small batches? Evaluate the complexity of your designs. Each application may require different settings and techniques. Identify your budget constraints too. It's essential to find a model that meets your requirements without overspending.

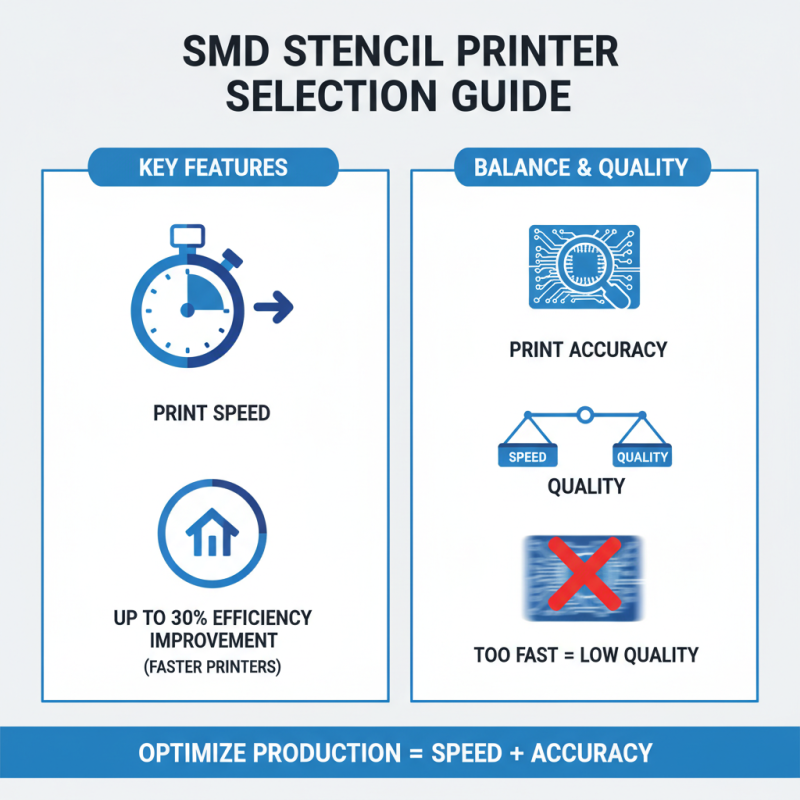

When selecting the right SMD stencil printer, it's essential to pay attention to key features. Print speed is one important aspect. Industry reports indicate that faster printers can improve production efficiency by up to 30%. However, speed should be balanced with print accuracy. A printer that prints too quickly often sacrifices the quality of the output.

Another critical feature is the size of the printer. Depending on your production needs, a compact printer may be suitable for small-scale operations. Conversely, large-scale manufacturers may require larger printers to accommodate various board sizes. Always assess your future needs. Investing in the wrong size could lead to unnecessary costs later.

Tips: Look for a printer with adjustable squeegee pressure. This flexibility can enhance paste deposition quality. Also, consider the ease of cleaning and maintenance. Some models are difficult to clean, which can lead to downtime. Finally, always read user reviews to gauge real-world performance. Not every printer may live up to its specifications.

When selecting the right SMD stencil printer, consider your specific production needs.

Assessing your volume requirements is crucial. High-volume production lines may need faster machines.

These models usually offer automated features. However, they can be costly.

A balance between price and performance is essential.

Evaluate your typical output. Smaller operations often favor compact, manual printers.

They can still deliver quality results without overwhelming costs.

Think about the number of units you produce daily. A printer that’s too small can slow down your process.

Yet, an oversized machine may lead to wasted resources.

Don't forget maintenance routines. Some printers require frequent upkeep, which can disrupt production.

Research user reviews to understand common issues. Reflect on your long-term needs.

A printer that works today may not suffice in the future. Planning for growth is vital.

Align your choice with both current and future demands.

Choosing the right SMD stencil printer can be challenging, especially when budget constraints come into play. A clear financial plan is essential to ensure you choose a printer that meets your needs without overspending. Prices vary widely based on capabilities and features. It's easy to fall into the trap of prioritizing low cost over necessary functions. Reflect on what you really need.

Tip: Assess your printing volume. If you don’t print often, a low-cost model may suffice. For high volumes, consider investing in a pricier, more efficient machine. A balanced approach can lead to better long-term savings.

Be mindful of hidden costs too. Supplies like stencils, inks, and maintenance can add up. Don’t overlook these expenses in your budget. A seemingly affordable printer might end up costing you more in the long run.

Tip: Research and compare total costs. This includes initial investment and ongoing expenses. Knowing these figures can prevent unexpected financial strain. Sometimes, a higher upfront cost can yield savings over time. Evaluate multiple options before making a decision.

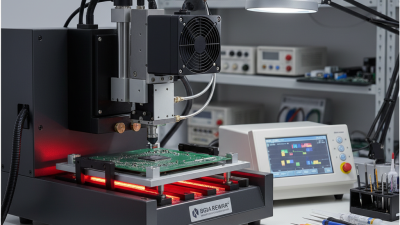

Maintenance plays a pivotal role in prolonging the lifespan of SMD stencil printers. Regular upkeep prevents breakdowns and costly repairs. According to industry standards, 70% of printing faults arise from improper maintenance. This underscores the necessity of a structured maintenance plan. A simple procedure like daily cleaning can significantly enhance performance. Neglecting this may lead to uneven squeegee pressure or misalignment, resulting in subpar prints.

Technical support is equally crucial. Research indicates that 60% of companies experience operational downtime due to inadequate support. Efficient customer service can help troubleshoot issues swiftly. It’s essential to assess support options when selecting a printer. A comprehensive warranty can provide peace of mind. However, many companies overlook this detail, risking their investment. Balancing initial costs with support quality can be tricky, but it is vital for sustained productivity. Regular training for staff on printer operation can also streamline processes and reduce errors.

| Feature | Description | Importance | Maintenance Tips |

|---|---|---|---|

| Print Speed | Measured in mm/sec, indicates how fast a printer can print. | High | Regularly check the printer settings and calibrate as necessary. |

| Precision | Accuracy in placement of materials (tolerance levels). | Critical | Keep the printing area clean and use high-quality stencils. |

| User-Friendliness | Ease of use and setup for operators. | Moderate | Regular training for operators on machine usage and updates. |

| Support and Service | Availability of technical support and spare parts. | High | Establish a relationship with the service provider for quicker response. |

| Cost of Ownership | Total cost including purchase price, maintenance, and materials. | Critical | Regularly review maintenance costs to avoid unexpected expenses. |