-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

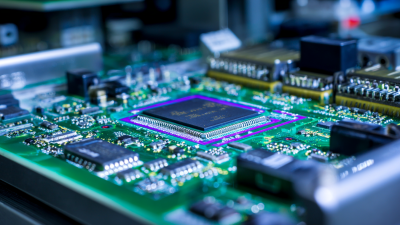

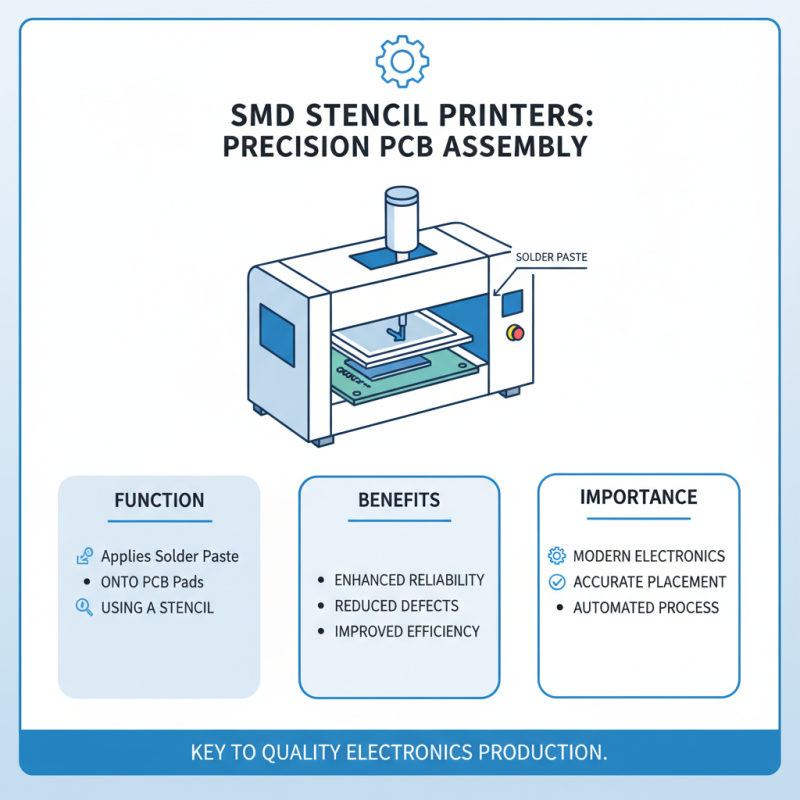

In the fast-paced world of electronics, efficiency is key. The SMD Stencil Printer is becoming essential for PCB assembly. It enhances productivity and ensures precision. With it, manufacturers can deliver high-quality products quickly. The SMD Stencil Printer simplifies the application of solder paste. This leads to fewer errors during assembly.

However, not all printers are created equal. Some may struggle with alignment issues. Others might require constant calibration, causing downtime. It’s crucial to consider these factors before making a purchase. A well-chosen SMD Stencil Printer streamlines the production process. Still, selecting the right model demands careful thought.

Investing in a quality printer pays off in the long run. Companies will see improved accuracy and reduced wastage. But, it’s worth noting that the transition may introduce challenges. Adapting to new technology takes time and training. Ultimately, the right SMD Stencil Printer can revolutionize assembly processes. Yet, constant reflection and adjustment are necessary for lasting success.

Using an SMD stencil printer for PCB assembly offers numerous benefits. These printers are designed for precision. They apply solder paste consistently across the surface mount device (SMD) pads. This accuracy reduces the risk of shorts and the need for rework. A well-printed stencil ensures proper solder volume, which is vital for reliable connections.

Tips: Always clean the stencil before use. This helps to avoid paste build-up. A clean stencil contributes to better print quality.

SMD stencil printers also improve efficiency. They allow for faster production times, which can lead to cost savings. However, be aware of setup times. Improper alignment can lead to defects. It’s important to practice and refine the setup process regularly to avoid mistakes.

Using a stencil printer doesn't eliminate challenges. Operators must monitor the print quality continuously. Even minor issues can affect the entire assembly. Regular inspections and adjustments are essential.

| Benefit | Description | Impact on PCB Assembly |

|---|---|---|

| Increased Efficiency | SMD stencil printers enable faster application of solder paste, significantly reducing assembly time. | Higher throughput and improved production rates. |

| Precision Application | Enables accurate placement of solder paste in fine pitch components, minimizing defects. | Reduced rework and improved yield rates. |

| Cost-Effectiveness | Lower manual labor costs and reduction in material waste. | Overall lower assembly costs and increased profit margins. |

| Flexibility | Adaptable to various board sizes and paste types, making it suitable for diverse projects. | Accommodates a range of production requirements. |

| Improved Quality Control | Consistent process leads to higher quality of solder paste application. | Fewer defects and higher reliability of PCB assemblies. |

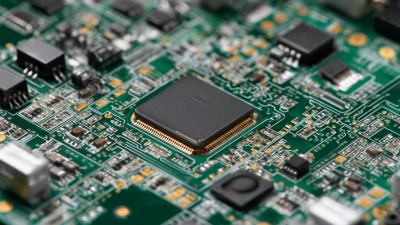

SMD stencil printers significantly improve the quality of PCB assembly. These printers ensure precise application of solder paste on circuit boards. The accuracy of the printing process is crucial. Even slight misalignment can lead to defects. Properly aligned prints reduce the risk of component failure.

With advanced technology, SMD stencil printers can achieve repeatable results. They can handle various components, regardless of size. This adaptability enhances production efficiency. Fine-pitch components are often challenging. However, effective stencil printing makes it manageable.

Operators often face difficulties in achieving uniform paste deposition. Inconsistent paste application can cause issues like bridging or tombstoning.

Attention to detail during the printing setup is vital. Even small errors can disrupt the entire assembly process. Regular calibration and maintenance of printers help prevent these issues. Operators must stay vigilant, noting any unusual results. Printing quality can directly influence the overall reliability of PCBs. Reflecting on the printer's performance is essential for continuous improvement.

When considering an SMD stencil printer for PCB assembly, it’s crucial to focus on specific key features. Precision is paramount. Research indicates that printers with an accuracy of 0.1 mm or better significantly reduce assembly errors. This accuracy impacts not just performance but also yield rates. Assemblies with aligned components lead to fewer defects and waste.

Another important feature is versatility. A good SMD stencil printer should handle various PCB sizes and paste types. This can adapt to the evolving needs of productions. According to industry reports, organizations that use versatile printers can increase throughput by up to 30%. However, the challenge lies in selecting a printer that balances flexibility with reliability. Not all printers deliver consistent results across different setups and formats.

Lastly, consider the printer's ease of use. Intuitive software can streamline the setup process. Complicated interfaces often frustrate operators and lead to mistakes. A user-friendly machine can reduce training time by 50%, as per industry surveys. Yet, users should remain cautious, as ease can sometimes come at the expense of deep functionality. Always assess whether a simple interface meets all production needs before finalizing a choice.

When considering SMD stencil printers for PCB assembly, cost-effectiveness stands out. These printers reduce material waste significantly. They ensure a consistent paste application, minimizing errors and rework. This precision boosts the production rate, which is crucial for manufacturers facing tight deadlines. It's about balancing cost and efficiency.

Savings extend beyond material usage. Automated processes cut down labor costs. The initial investment may seem high, but the long-term savings are undeniable. However, not all manufacturers may see immediate returns. Frequent maintenance can disrupt workflows. Some might struggle with learning curves, slowing down production initially. These are real challenges to address.

Quality is paramount in PCB assembly. Even the best printers can encounter issues. A misalignment can lead to defective boards. Thus, training staff on proper operation is vital. Continuous improvement in processes and equipment can mitigate such problems. Reflecting on these aspects ensures that manufacturers optimize their investment effectively.

SMD stencil printers play a crucial role in PCB assembly. They ensure precise application of solder paste onto circuit boards. This technique is essential in modern electronics production. Accurate paste application enhances the reliability of electronic devices. SMD printers improve manufacturing efficiency by reducing human error.

Tips: Always calibrate your printer before use. Calibration ensures consistent results. Check the stencil cleanliness regularly. Residue can cause defects in solder paste application.

Using an SMD stencil printer can be a game changer. However, it's not always foolproof. Operators may face challenges in aligning stencils with boards perfectly. Misalignment can lead to defects, making it necessary to practice quality control. More training on stencil handling could be beneficial.

Tips: Invest time in operator training. Better-trained staff will produce superior quality work. Also, maintain a clean workspace to avoid contamination. Cleanliness is vital in maintaining print quality.