-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

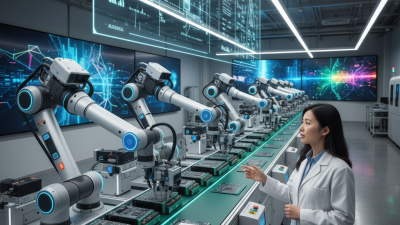

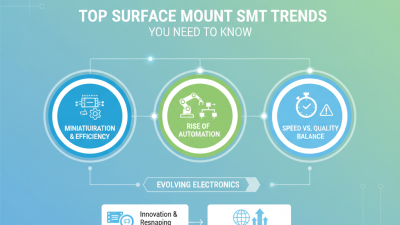

The selection of a PCB Pick and Place Machine can significantly impact manufacturing efficiency and product quality. According to a report by MarketsandMarkets, the global PCB assembly market is expected to reach $78 billion by 2025, highlighting the growing importance of advanced machinery in this sector. Industry expert John Smith states, "Choosing the right PCB Pick and Place Machine can make or break your production line." His insight underscores the need for careful consideration when investing in this essential equipment.

Manufacturers face tough choices. The variety of machines on the market can be overwhelming. Key factors, including placement accuracy, speed, and ease of use, must be evaluated. Often, companies focus solely on price, neglecting long-term operational costs and reliability. This oversight can lead to increased downtime and repair costs, undermining initial savings.

Choosing a PCB Pick and Place Machine requires a deep understanding of specific needs. The wrong decision may hinder production quality and efficiency. Thus, thorough research and expert consultation are crucial. Balancing budget constraints with desired capabilities is also vital. Success in PCB assembly starts with choosing the right technology.

Choosing a PCB pick and place machine requires careful consideration. One vital aspect is your production volume. High-volume operations need fast and efficient machines. However, for smaller projects, an entry-level option may be sufficient. This balance is crucial to avoid overspending on features you don't need.

Another important factor is the complexity of the PCB designs. Consider whether your devices include fine-pitch components. If they do, look for machines with high precision. It's essential to assess the maximum speed and accuracy. While many machines promise high speeds, ensure they deliver consistent results.

User-friendly software is a must. Intuitive interfaces can save time during setup and operation. However, some systems can be complex, causing frustration. Test the software thoroughly before making a decision. It's also wise to consider the machine's maintenance needs. Regular upkeep can lead to downtime if overlooked. Investing time in proper training can prove beneficial in the long run.

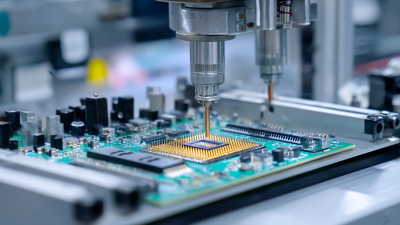

In the world of electronics manufacturing, SMD placement accuracy is crucial. Reports indicate that 50% of defects in PCB assemblies stem from improper placement of components. This can lead to failures in function or performance. Precision is not just a goal; it’s a necessity. A small misalignment can cause significant issues in the final product.

Factors influencing placement accuracy include machine calibration and environmental conditions. A poorly calibrated machine can lead to 0.1 mm deviation, which can dramatically affect circuit performance. Temperature fluctuations or humidity can also alter component behavior. In some cases, this can result in up to 20% decreased yield in production. Investing in a reliable machine is vital, but constant monitoring of these conditions is equally important.

Every manufacturer should consider the broader implications of placement accuracy. A single faulty board can derail production schedules and increase costs. It may even tarnish a company's reputation. Achieving high accuracy is not effortless; it demands continuous improvement and adaptation. Regular training for operators and updating practices can enhance outcomes significantly. Every detail in the SMD placement process can lead to either success or failure, emphasizing its importance in quality control.

This chart demonstrates the importance of SMD placement accuracy for quality control in PCB manufacturing based on 10 tips. Each tip is evaluated for its effectiveness in ensuring high precision and reliability in the placement of surface-mount devices.

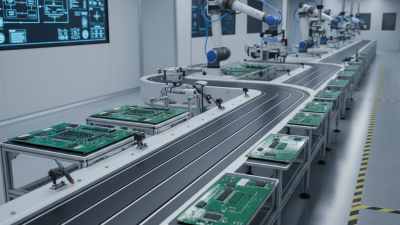

In high-volume production, the speed of a PCB pick and place machine is crucial.

Faster machines can significantly increase output. However, speed isn’t the only factor.

It’s essential to consider the overall accuracy and reliability of the machine.

A fast machine might seem advantageous, but what if it compromises precision? That could lead to costly errors.

Evaluating specifications can be complex. Look for items like placement rate and component handling capabilities.

A machine with a high placement rate but insufficient component diversity may not meet all your needs.

You might encounter trade-offs between speed and flexibility. Each production line has unique requirements, and

balancing these is key.

Testing machines in real-world conditions can provide insight. Sometimes, benchmarks in lab settings don't reflect actual performance.

Moreover, setup time and programming can impact efficiency. If the machine takes too long to set up, gains in speed

during operation might be negated. Reflecting on these aspects ensures you choose the right machine for your specific

production goals.

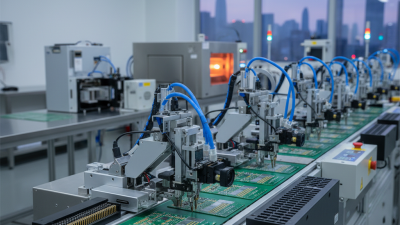

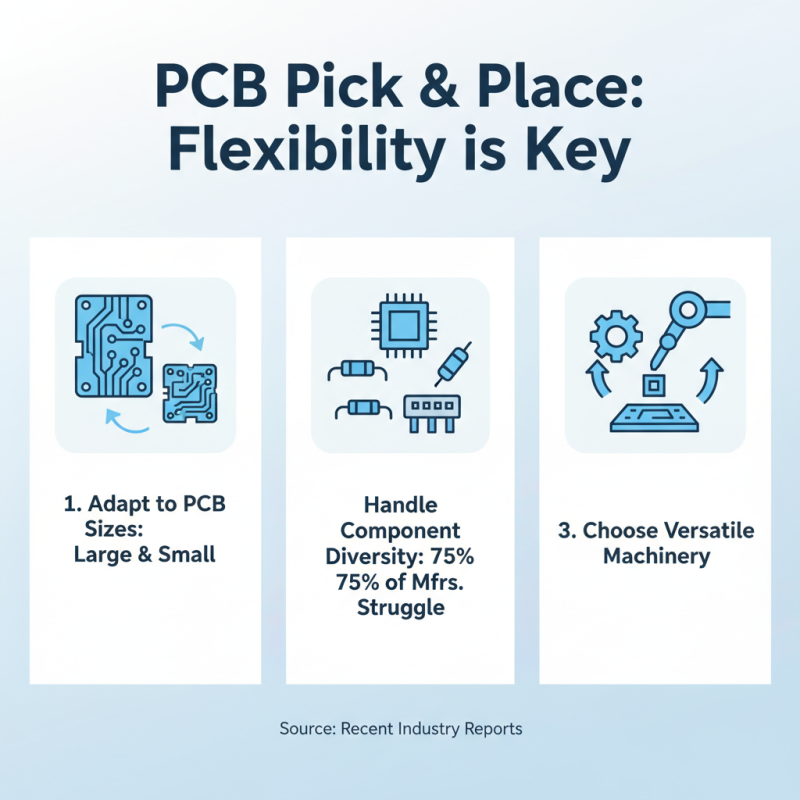

When selecting a PCB pick and place machine, compatibility with various PCB sizes and component types is crucial. According to recent industry reports, over 75% of electronic manufacturers face challenges related to component diversity. This highlights the need for flexibility in machinery to accommodate both large and small PCBs.

Consider the machine's specifications carefully. Some machines only support specific board sizes, limiting production capabilities. The average PCB size for consumer electronics is around 10x10 cm, but larger applications require machines that can handle sizes up to 30x30 cm or more. If your operation frequently shifts between sizes, a more adaptable pick and place machine is essential.

Additionally, evaluate the machine's ability to handle different component types. Components vary in shape, size, and weight, which affects placement precision. A study shows that 60% of placement errors occur due to incompatible component handling. Investing in equipment that can manage a range of components, from SMDs to larger ones, can minimize these errors. Reflecting on these factors is vital for enhancing production efficiency and avoiding costly mistakes in the assembly process.

Choosing the right PCB pick and place machine can be daunting. A machine's software features play a crucial role in improving efficiency. An intuitive interface can significantly reduce operating errors. For instance, easy-to-navigate menus help operators quickly adjust settings, minimizing downtime. Real-time feedback on placement accuracy is invaluable. It allows for immediate corrections, reducing waste and enhancing productivity.

Understanding the software's capabilities is essential. Automated programs for component recognition can save time. However, this technology isn't flawless. Occasionally, misrecognition may occur, leading to improper placements. It's wise to consider a machine that allows manual overrides. Operators should have the option to intervene when necessary. This flexibility can prevent larger issues down the line.

Data analysis features are another great asset. They help track performance and efficiency over time. Analyzing this data is not always straightforward. Workshop conditions and machine calibration can vary. Regularly review these metrics for informed decision-making. A machine that provides detailed reports can help pinpoint recurring issues, guiding future improvements.