-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

As the electronics production landscape evolves, selecting the right SMD reflow oven becomes crucial. Industry reports indicate that the global reflow oven market is projected to grow by over 5% annually, driven by increased demand for compact and efficient components. Companies face numerous options, which can be overwhelming.

Many factors influence this decision. Features like temperature control, energy efficiency, and throughput are vital. For instance, a high-end SMD reflow oven can significantly reduce cycle times. However, not every manufacturer requires such advanced technology. Understanding specific production needs is essential.

Choosing the wrong oven can lead to significant setbacks. Poorly selected equipment may increase production costs and extend lead times. Striking a balance between quality and budget is often challenging. Therefore, careful evaluation of operational requirements and future growth is necessary for making an informed choice.

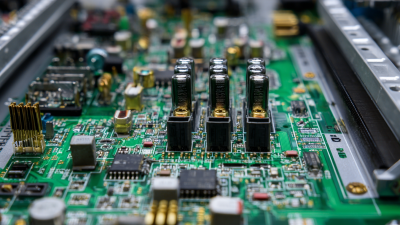

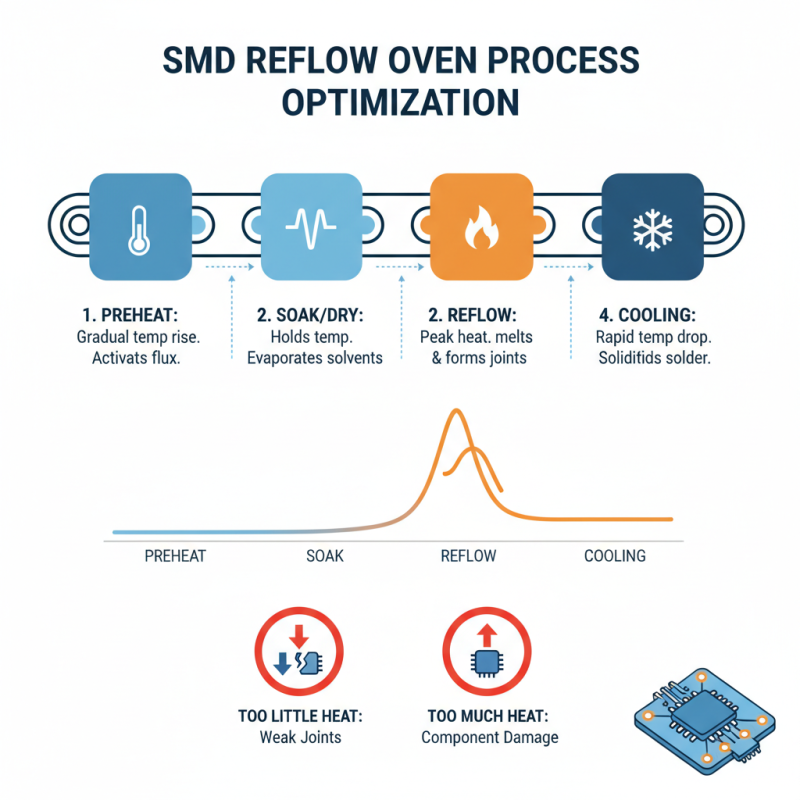

SMD reflow ovens play a crucial role in the electronics manufacturing process. They are essential for soldering surface-mount devices (SMDs) onto circuit boards. Understanding how these ovens work is vital for optimizing production efficiency. The heating process must be carefully controlled. Too much heat can damage components. Too little can result in weak solder joints.

Choosing the right oven involves several key factors. One important aspect is temperature profiling. Different components have different soldering requirements. Effective profiling prevents damage and enhances the overall quality of the soldering process.

**Tips:** Consider investing in an oven with programmable features. These allow for precise temperature adjustments. Regular maintenance of the oven is also critical. It ensures consistent performance over time. Get feedback from operators about any issues that arise during use. Their insights can help refine the process.

Another critical factor is the size of the oven. Ensure it can accommodate your production volume. A small oven may lead to bottlenecks. On the other hand, an oversized unit could waste energy. Balancing these factors is a task that needs careful consideration.

Choosing the right SMD reflow oven for electronics production in 2026 can feel overwhelming. The market offers many options, making decisions tricky. One key feature to consider is temperature accuracy. Ensure the oven maintains consistent heat throughout the entire process. Inconsistent temperatures can lead to poor soldering quality.

Another critical aspect is the oven's size. Evaluating the production scale is essential. A smaller oven may suffice for low-volume production. However, larger operations require a bigger oven with increased capacity. Think about the future as well. Investing in a scalable solution might be wise.

It's also important to look at the control system. User-friendly controls make operation smoother. Complex interfaces can lead to mistakes. Many ovens come with built-in profiles for different components. Yet, not all may suit your requirements. Testing different options can help identify what works best. Lastly, consider the maintenance needs. Frequent maintenance can slow production. Choosing an oven with easy-to-service components may save time in the long run.

When selecting the right SMD reflow oven for your 2026 electronics production, understanding your production needs is crucial. As per a recent industry report, over 70% of manufacturers plan to increase production capacity by 2026. This surge reflects the growing demand for advanced electronics in sectors like automotive and healthcare. Evaluating your specific requirements helps in choosing the appropriate features and specifications of the oven.

A critical factor is the volume of production. If your production line is expected to ramp up, an oven with higher throughputs is essential. Many manufacturers currently face challenges in meeting rapidly changing demands. Adapting to these challenges means investing in flexible equipment that accommodates varied component sizes and types. The right oven can enhance throughput without compromising quality.

Tips: Assess the maximum board size your operation requires. Look for ovens that offer precise temperature control. Regular training for operators is also essential. It helps prevent errors and increases overall efficiency. Reflect on your current operations. Are they optimized for future growth? If not, it may be time to reconsider your equipment choices. As trends evolve, businesses must stay agile.

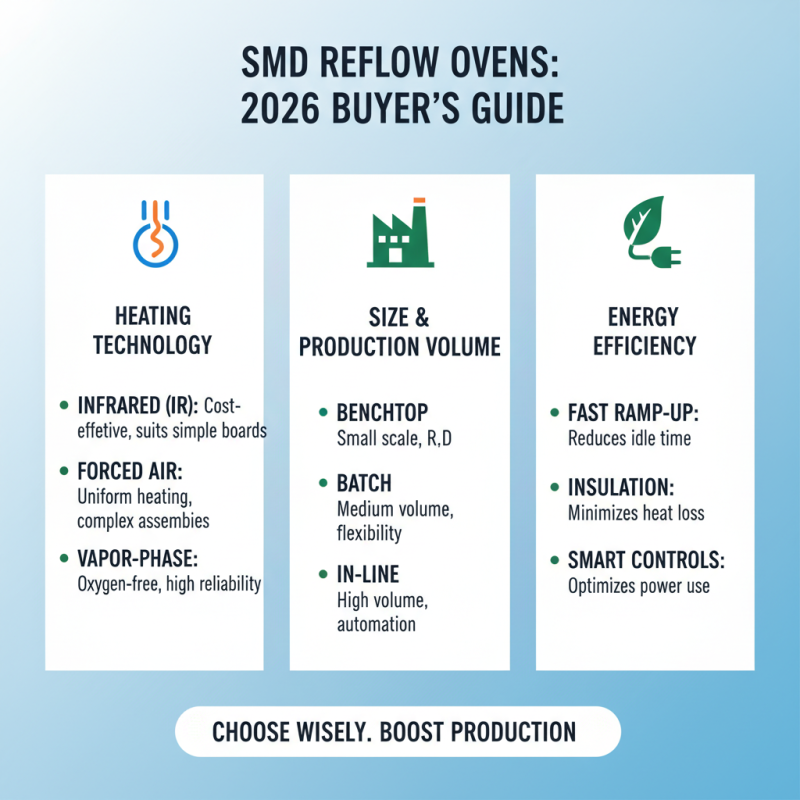

Choosing the right SMD reflow oven can significantly impact your electronics production in 2026. Different types of ovens cater to various needs. When comparing options, consider factors like heating technology, size, and energy efficiency.

One popular option is the convection reflow oven. It uses hot air to heat the PCB consistently. This method can result in uniform heating, but it might not be suitable for all components. Infrared reflow ovens offer another alternative. They use infrared energy for faster heating, but can lead to uneven results if not monitored correctly. Choose based on your specific requirements.

**Tips:** Look for ovens with adjustable temperature profiles. This feature provides flexibility for different solder types. Additionally, consider the oven's footprint, especially if space is limited. It's okay if your choice isn’t perfect; reflection on the production process can lead to better decisions later. Be prepared to adapt your techniques based on the oven performance.

When budgeting for an SMD reflow oven, it's crucial to evaluate your production needs. Start by determining the volume of electronics you plan to produce in 2026. This will guide you on how much automation you require. Consider the types of components you will work with. Larger or more complex boards may need advanced ovens.

Next, analyze the overall costs. SMD reflow ovens can vary significantly in price. A higher initial investment may lead to better efficiency and fewer maintenance issues. However, cheaper models might seem appealing at first. Think about potential downtimes and repairs. Every breakdown can cost more in the long run.

Include operational expenses in your budget. Electricity usage, soldering materials, and staff training should all be accounted for. Remember, initial savings might overshadow long-term benefits. Investing time in cost analysis now can prevent future regrets.

Adjust your budget according to realistic growth predictions, avoiding overly optimistic estimates. This ensures you make a well-informed purchase decision.