-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

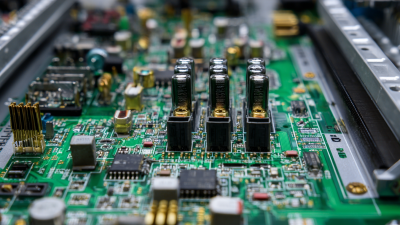

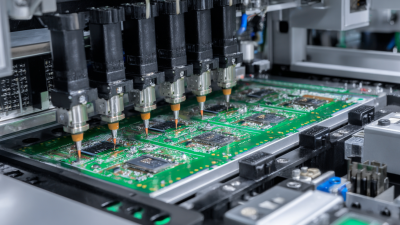

In the rapidly evolving landscape of electronics manufacturing, the choice of equipment plays a critical role in enhancing productivity and ensuring high-quality outputs. Among the many essential components in the manufacturing process, the PCB conveyor stands out as a vital element that facilitates the efficient movement of printed circuit boards (PCBs) between various stages of production. Selecting the right PCB conveyor is not merely a matter of functionality; it involves a careful evaluation of specific needs tailored to your operational requirements.

As the demand for precision and speed increases, understanding how to choose the best PCB conveyor can significantly influence overall workflow efficiency. This guide will explore the fundamental factors that should be considered when selecting a PCB conveyor, supplemented with practical tips to help manufacturers make informed decisions. From assessing conveyor speed and width to understanding the importance of system compatibility, the right PCB conveyor can enhance both the quality and speed of production, ultimately leading to a more streamlined manufacturing process. Whether you're a small-scale operation or a large manufacturing entity, making the right choice in PCB conveyor systems is essential for maintaining a competitive edge in today's market.

When selecting the right PCB conveyor for your manufacturing needs, it's essential to understand the different types available and their specific industrial applications. PCB conveyors are integral to the production line, facilitating the efficient movement of printed circuit boards during assembly. There are several types, including belt conveyors, chain conveyors, and modular conveyors, each serving distinct roles depending on the production requirements. For instance, belt conveyors are ideal for lightweight PCBs, while chain conveyors are better suited for heavier loads.

Tips: Consider the size and weight of your PCB when choosing a conveyor type. It's crucial to match the conveyor's capabilities with your production materials to enhance efficiency. Additionally, think about the layout of your facility; modular conveyors can be tailored to fit specific space constraints and workflow patterns.

Moreover, maintaining the conveyor system is vital for ensuring longevity and optimal performance. Regular inspections and timely repairs can prevent costly downtimes. Evaluate automation options to streamline operations further and reduce manual handling, which can lead to increased productivity and improved safety in the manufacturing environment.

| Type of PCB Conveyor | Application | Advantages | Considerations |

|---|---|---|---|

| Conventional Conveyor | General assembly lines | Cost-effective, easy to install | Limited flexibility |

| Modular Conveyor | Customizable manufacturing setups | Flexible design, scalability | Higher initial cost |

| Vertical Conveyor | High-rise manufacturing facilities | Space-saving, efficient | Complex installation |

| Overhead Conveyor | Assembly lines with limited floor space | Unobstructed floor area | Higher maintenance costs |

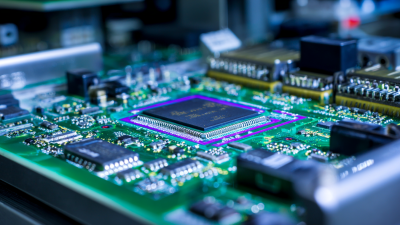

When selecting a PCB conveyor for your manufacturing needs, several key factors must be taken into account. First and foremost, the conveyor's compatibility with your existing production line is crucial. You need to consider the size and dimensions of the PCB components you will be handling. Different conveyors come with varying width and height specifications to accommodate diverse product sizes. Additionally, the type of materials being transported can influence your choice; ensure that the conveyor can manage the specific boards and components without causing damage or delays.

Another significant factor is the conveyor's speed and capacity. Depending on the production volume, you may need a conveyor that can operate at higher speeds while maintaining precision in handling. Evaluate the conveyor’s throughput rate to ensure it aligns with your manufacturing demands. Furthermore, consider the control systems and automation features that facilitate integration with other machinery, enhance efficiency, and reduce labor costs. Finally, maintenance requirements and the availability of spare parts are essential for keeping the conveyor operational with minimal downtime.

When selecting the best PCB conveyor for your manufacturing needs, understanding the comparison of different PCB conveyor technologies is essential. The two most common types are belt conveyors and chain conveyors.

Belt conveyors are known for their versatility and ease of use. They can handle various PCB sizes and shapes, making them ideal for manufacturers with diverse product lines. They generally operate quietly and require less maintenance, which can lead to lower operational costs.

On the other hand, chain conveyors provide superior stability and durability, especially for heavier PCBs. They are often used in high-throughput environments where consistent speed and reliability are critical. Chain conveyors can also be advantageous in specific setups, such as when dealing with extreme temperatures or chemicals that might degrade belt materials.

Ultimately, the choice between these technologies should be based on your specific manufacturing requirements, including the size of the PCBs, the production volume, and the environmental conditions of your operation.

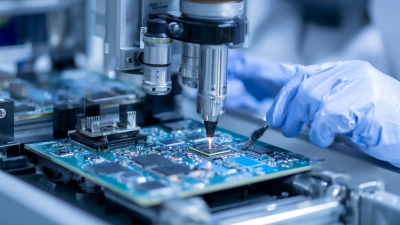

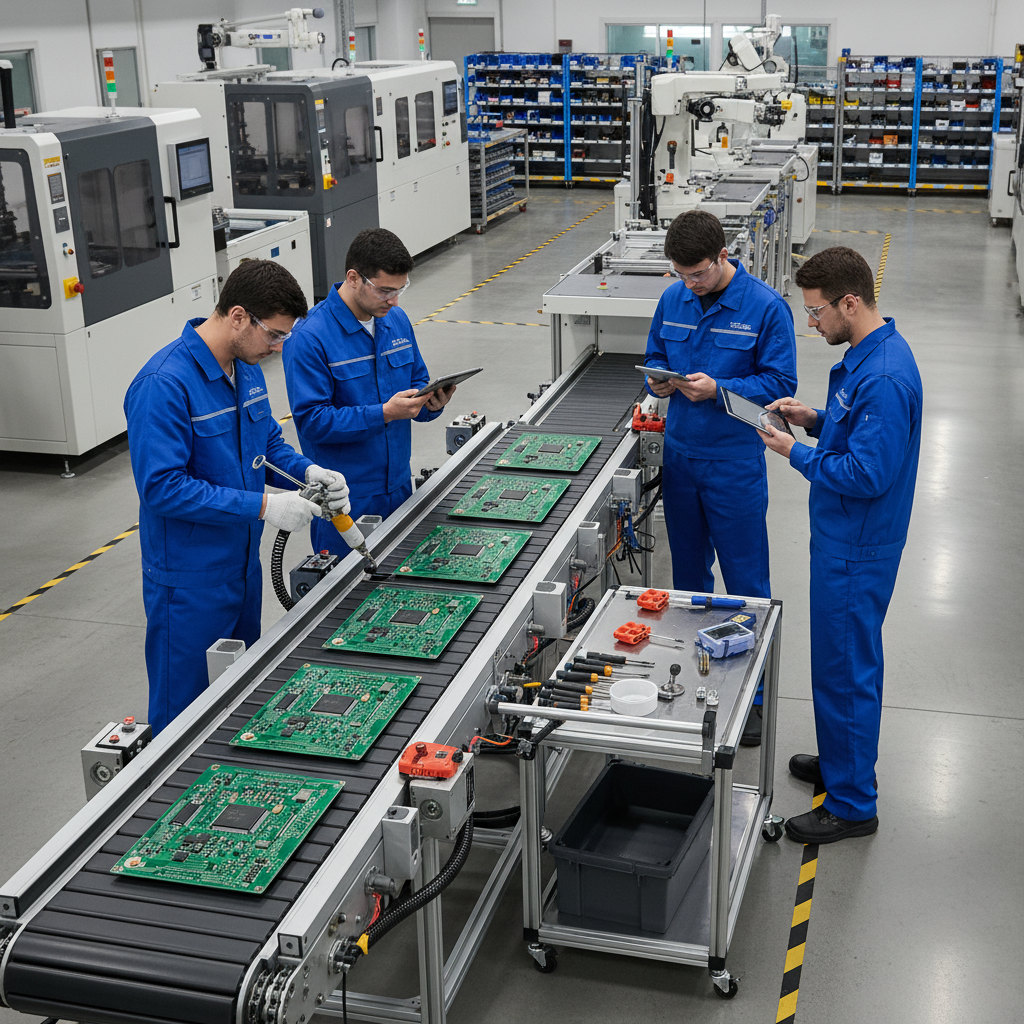

When selecting a PCB conveyor, customization plays a critical role in optimizing the manufacturing process. According to a report from Market Research Future, the global PCB conveyor market is anticipated to grow at a compound annual growth rate (CAGR) of 6% from 2020 to 2027, indicating the increasing demand for tailored solutions. A conveyor designed specifically for your production line can significantly enhance efficiency, reduce bottlenecks, and improve product quality.

Customization to specific manufacturing processes often involves adjusting conveyor speed, height, and configuration to meet unique operational requirements. Many manufacturers are now employing modular conveyor systems, allowing for easy adjustments and expansions as production demands evolve. A recent industry survey highlighted that 85% of manufacturers report increased productivity after integrating customized conveyors into their workflows. This statistic underlines the importance of assessing your process requirements and considering bespoke features, such as integrated inspection stations and automated sorting capabilities, to achieve streamlined operations and maximize throughput.

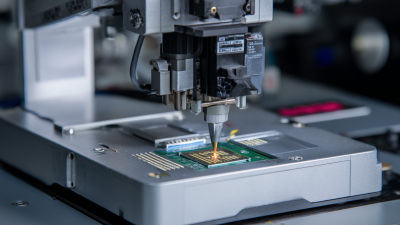

When selecting a PCB conveyor system, maintenance and support play a crucial role in ensuring optimal performance and longevity.

According to a report by IPC, approximately 30% of manufacturing downtime is attributed to equipment malfunctions, with poor maintenance being a significant factor.

Regular maintenance of PCB conveyors not only minimizes unexpected breakdowns but also enhances productivity, allowing manufacturers to maintain their competitive edge in the fast-paced electronics industry.

Moreover, having a reliable support system in place can significantly impact the efficiency of operations. Studies indicate that businesses with access to 24/7 technical support can reduce system downtime by as much as 20%.

Being able to quickly address any issues that arise ensures that production lines remain operational. Manufacturers should consider partnerships with suppliers that offer comprehensive maintenance agreements, including training for staff, timely parts replacement, and proactive service checks.

This strategic approach not only protects the investment in equipment but also aligns the conveyor system capabilities with evolving manufacturing demands.