-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

Choosing the right SMT machine for your manufacturing needs is crucial. The right equipment impacts efficiency and product quality. With various models available, the decision can be overwhelming.

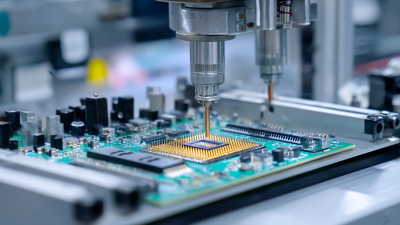

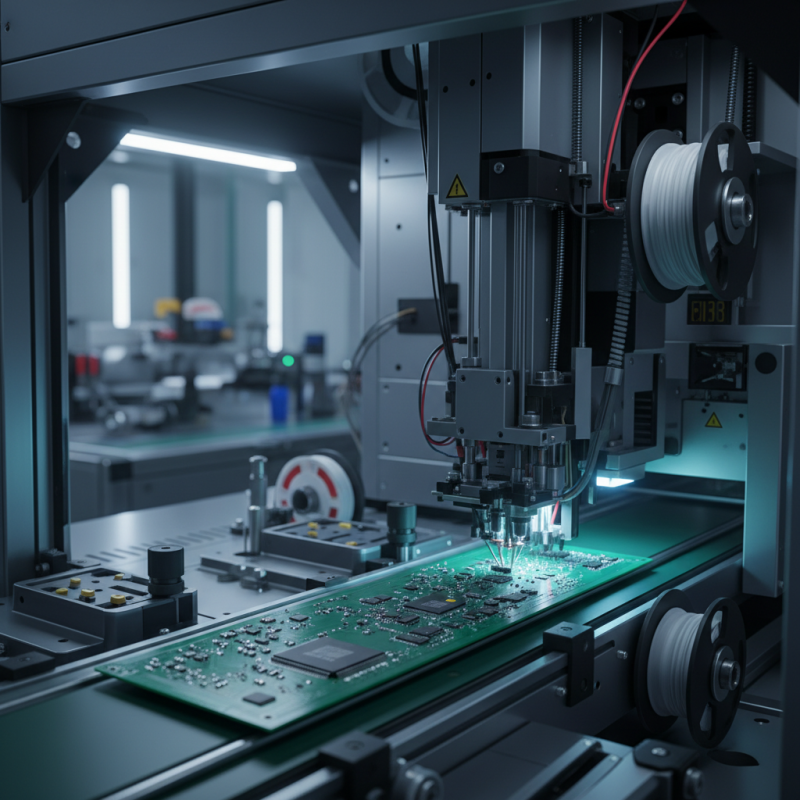

An SMT machine is essential for many electronics manufacturers. It places components on PCBs with precision. Consider your production volume and types of products. A high-speed machine may seem appealing but may require more maintenance.

It is vital to assess your actual needs versus industry trends. Some find that lower-cost machines serve their purposes well. Others invest heavily, only to discover they do not utilize many features. Reflect on your production goals. This reflection will guide you in making an informed decision.

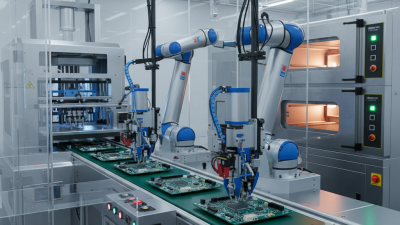

Surface Mount Technology (SMT) machines play a crucial role in modern manufacturing. These machines enable efficient assembly of electronic components on printed circuit boards. With the growing complexity of electronic devices, SMT machines have become essential. They significantly increase production speed and accuracy, which is vital in today’s market.

When selecting an SMT machine, consider several factors. Think about the scale of your production and the types of components you use. Each machine has specific capabilities that might not suit all manufacturing needs. Some machines handle small components well, while others excel with larger ones. It's important to evaluate not just the features, but also the ease of use.

Budget is another significant aspect. High-end machines may offer advanced features but require significant investment. It might be tempting to go for cheaper options. However, consider the long-term costs of maintenance and potential productivity losses. Striking a balance between cost and functionality is key. Investing in the right technology can lead to better product quality and customer satisfaction.

When choosing an SMT machine, it’s crucial to assess your manufacturing requirements and production volume. Start by determining what types of products you will produce. This decision impacts the specifications of the machine you need. Different products require different technologies and capabilities. Consider how many units you anticipate producing each day. A smaller batch may not require high-end machinery, while larger volumes demand efficiency and speed.

Production volume influences machine selection significantly. If your volume fluctuates, you might need a versatile machine. Consider future growth too. Will your production needs expand? If so, investing in a machine with higher capacity could be wise. Assessing your workspace is equally important. Some machines require more floor space, which can limit options. It’s also vital to reflect on the ease of operation. Can your team efficiently operate the machine? Complexity can lead to errors and delays.

Equipment can be costly, so weigh the initial investment against long-term benefits. Sometimes, cheaper machines fall short in performance. Reflect on maintenance aspects. Will you have adequate support and parts available? Balancing features and expenses can be tricky. Review your goals regularly to ensure alignment with your manufacturing strategy. The right decision now can significantly influence your operation's success later.

When selecting an SMT machine, various key features should be on your checklist. First, consider the machine's placement accuracy. High precision is vital for modern electronic components. A machine that offers repeatable placements will reduce rework and waste. Look for specifications that highlight this accuracy clearly.

Next, evaluate the machine's speed. Different production lines have varying demands. Some setups may prioritize speed over precision. However, find a balance that suits your production needs. A machine that operates too quickly may sacrifice quality, leading to frequent issues. Think about the impact of downtime as well.

Additionally, flexibility is crucial. Your manufacturing needs may change over time. A machine that supports multiple component sizes can enhance your operations. However, not every machine offers such versatility. Sometimes, you might recognize that a great machine doesn't fit your evolving requirements. Reflecting on these aspects will guide your decision-making process effectively.

When selecting the right SMT machine for your manufacturing needs, budget constraints play a crucial role. A well-defined budget helps ensure you don’t overspend. Consider not just the initial cost, but also ongoing expenses. Maintenance and parts replacement can accumulate over time. You might find that a cheaper machine initially can cost more later due to frequent repairs.

Evaluating cost-effectiveness requires looking at your production goals. Think about the volume of units you need to produce. A machine that handles more units may save you money in the long run. However, if your production volume is low, investing heavily may not be wise. Don’t overlook training costs for your staff as well. Sometimes, a machine is affordable but requires extensive training to operate efficiently.

Choosing the right machine should not only be about the price tag. Take time to analyze the total cost of ownership. Reflect on your production needs for the next few years. Will the machine grow with your business? An impulsive decision can lead to regret later. Keep these aspects in mind as you make your choice.

| Machine Type | Initial Cost ($) | Operating Cost/Month ($) | Production Speed (PCs/hour) | Flexibility Rating (1-5) |

|---|---|---|---|---|

| Entry-Level | 20,000 | 1,500 | 200 | 3 |

| Mid-Range | 50,000 | 3,000 | 400 | 4 |

| High-End | 100,000 | 5,000 | 600 | 5 |

| Custom Solutions | Varies | Varies | Varies | 5 |

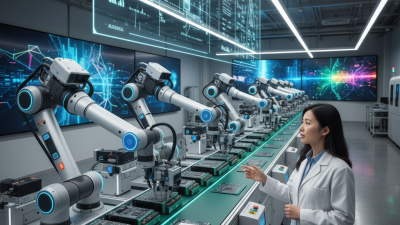

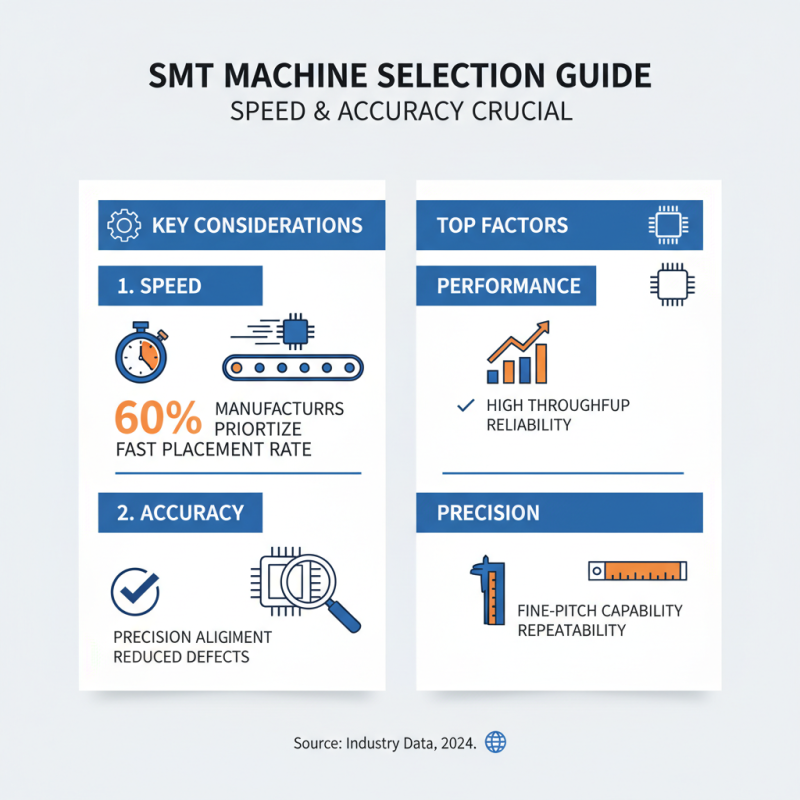

Choosing the right SMT machine requires careful comparison of brands and models. The market offers a plethora of options, each with unique features. For instance, recent data indicates that around 60% of manufacturers prioritize speed and accuracy. This data highlights the pressing need for machines with high performance and precision.

Moreover, comprehensive analyses show that user-friendly interfaces significantly impact productivity. A machine with an intuitive setup reduces training time by as much as 30%. It's important to consider the costs too. Many brands suggest that an investment today can yield up to 25% in cost savings over five years. However, weighing upfront expenses against potential long-term benefits can be challenging.

Some brands may claim superior reliability, yet user reviews often tell a different story. Many machines struggle in high-volume scenarios, leading to unexpected downtime. The complexity of features can be both a boon and a bane. While advanced capabilities attract attention, unnecessary functions might complicate processes. Manufacturers should critically assess their unique needs before making a choice.