-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

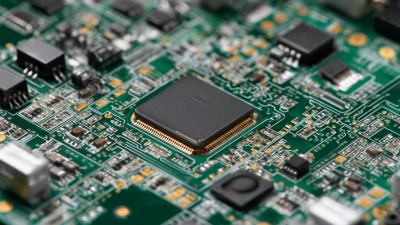

In the fast-evolving landscape of manufacturing, the adoption of advanced machinery is crucial for enhancing operational efficiency and productivity. Among the cutting-edge technologies making a significant impact is the Radial Insertion Machine. According to a 2022 report from the International Society of Automation, manufacturers utilizing radial insertion technology have experienced an average reduction in assembly time by up to 30%, significantly optimizing their workflow. Moreover, as reported by Market Research Future, the global market for insertion machines is projected to grow at a compound annual growth rate (CAGR) of 6.5%, underlining the increasing reliance on these systems for precision and efficiency in production lines. The integration of Radial Insertion Machines not only streamlines processes but also improves product quality, making it essential for companies aiming to remain competitive in today's dynamic market.

In the fast-evolving landscape of manufacturing, the adoption of advanced machinery is crucial for enhancing operational efficiency and productivity. Among the cutting-edge technologies making a significant impact is the Radial Insertion Machine. According to a 2022 report from the International Society of Automation, manufacturers utilizing radial insertion technology have experienced an average reduction in assembly time by up to 30%, significantly optimizing their workflow. Moreover, as reported by Market Research Future, the global market for insertion machines is projected to grow at a compound annual growth rate (CAGR) of 6.5%, underlining the increasing reliance on these systems for precision and efficiency in production lines. The integration of Radial Insertion Machines not only streamlines processes but also improves product quality, making it essential for companies aiming to remain competitive in today's dynamic market.

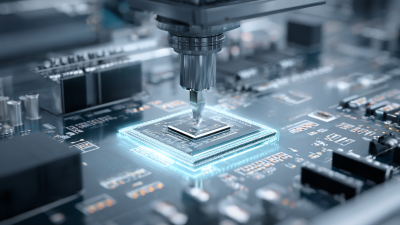

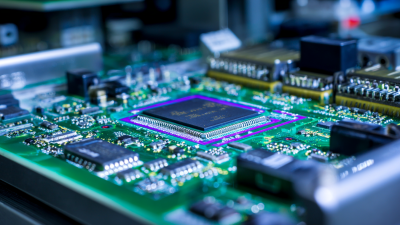

Radial insertion machines are revolutionizing the manufacturing landscape by enhancing efficiency and precision. These machines are designed for the seamless insertion of components into printed circuit boards (PCBs) and other assemblies. Key features include high-speed operation, minimal waste, and versatility in handling various component sizes. By automating the insertion process, manufacturers can significantly reduce labor costs while maintaining a high level of quality.

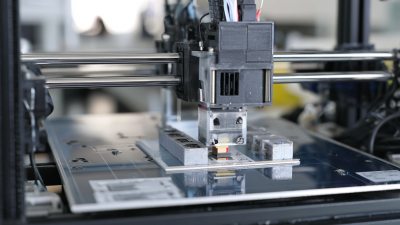

Tips for optimizing the performance of radial insertion machines include regular maintenance checks to ensure all moving parts function smoothly. Additionally, manufacturers should invest in training for operators to maximize the capabilities of the machines. This helps in minimizing errors and enhancing overall productivity. When selecting a radial insertion machine, it’s critical to assess your production needs and choose a model that offers flexibility and scalability for future growth.

Furthermore, understanding the benefits of radial insertion machines is key to fully utilizing their potential. These machines not only accelerate production times but also improve consistency in component placement. The increased accuracy reduces the likelihood of assembly defects, leading to higher customer satisfaction and lower return rates. With the right strategies in place, companies can truly harness the power of these advanced machines for their manufacturing operations.

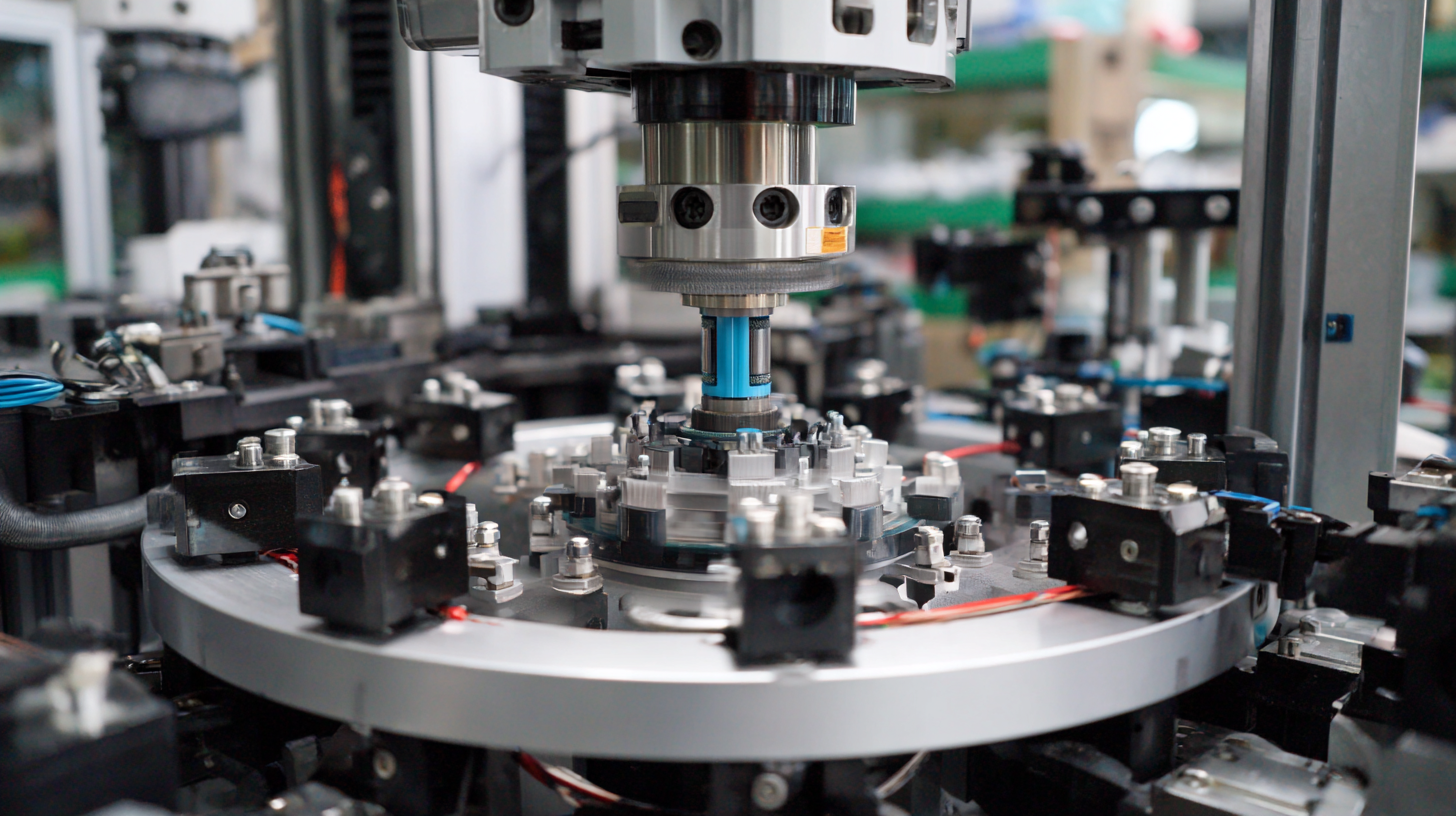

In modern manufacturing, the integration of radial insertion machines is a transformative force driving automation.

These machines significantly enhance production efficiency, allowing for high-speed assembly and precise component placement.

As factories adapt to the increasing demand for rapid output, radial insertion machines are becoming essential tools that streamline operations, reduce labor costs, and minimize human error.

Tips for Maximizing Automation with Radial Insertion Machines:

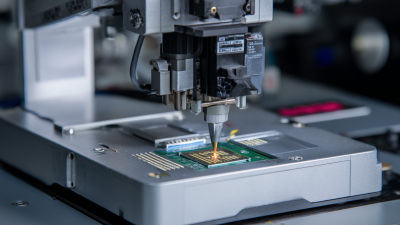

In the manufacturing sector, the comparison between radial insertion machines and traditional methods highlights significant advancements in efficiency and effectiveness. Radial insertion machines are engineered to automate and streamline the insertion process, reducing human error and increasing production speed. This innovative approach has been shown to outperform traditional methods, particularly in high-volume production environments, where precision and consistency are paramount. Incorporating radial insertion technology can result in substantial time savings and improved product quality.

Furthermore, similar to advancements seen in medical procedures, such as the transition from blind puncture techniques to ultrasound-guided methods, the manufacturing industry is witnessing a shift towards technologically advanced insertion methods. Traditional insertion often relies heavily on manual labor and carries a higher risk of variability in output quality. By leveraging machines designed for radial insertion, manufacturers can achieve a level of standardization and reliability that aligns with modern quality control demands. This shift not only enhances operational efficiency but also underlines the importance of embracing technological innovations to stay competitive in a rapidly evolving market.

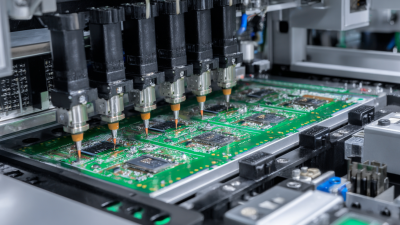

The manufacturing landscape is rapidly evolving, with radial insertion machines at the forefront of enhancing operational efficiency. These machines leverage advanced technologies and data-driven analytics to streamline manufacturing processes. By focusing on precision and speed, they significantly reduce operational costs and increase throughput, making them indispensable in modern production settings.

Recent industry statistics underscore the impact of radial insertion machines on productivity. Companies that have integrated these machines into their workflows report efficiency gains upwards of 30%, showcasing how data-driven insights can transform manufacturing operations. Furthermore, as organizations increasingly adopt AI and predictive analytics, the manufacturing sector is expected to see even greater improvements in process optimization and resource allocation, empowering businesses to stay competitive in a fast-paced market.

Maximizing productivity in manufacturing with radial insertion machines requires a strategic approach to both design and processes. These machines have the potential to enhance assembly line efficiency significantly by streamlining the insertion of components. To realize their full benefits, manufacturers should focus on optimizing machine operation and layout.

One effective tip is to ensure that the parts bin layout is organized and accessible. A well-arranged parts bin can reduce the time workers spend searching for components, thereby increasing the flow of production. This aligns closely with best practices observed in assembly lines, where efficiency is paramount.

Additionally, it is crucial to train staff on the best usage practices for radial insertion machines. Providing employees with thorough training not only enhances their comfort with the equipment but also minimizes errors, leading to a smoother operation. Incorporating regular feedback loops can further improve machine utilization, as operators can share insights on potential adjustments or maintenance needs. Implementing these strategies will contribute to a more productive manufacturing environment.

| Metric | Value | Industry Average | Best Practices |

|---|---|---|---|

| Productivity Increase (%) | 20% | 15% | Regular maintenance and operator training |

| Cycle Time Reduction (%) | 30% | 25% | Lean manufacturing principles |

| Error Rate (%) | 2% | 5% | Implement quality control measures |

| Energy Consumption (kWh/unit) | 0.5 | 0.7 | Use of energy-efficient machinery |

| Operational Downtime (%) | 5% | 8% | Proactive maintenance scheduling |