-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

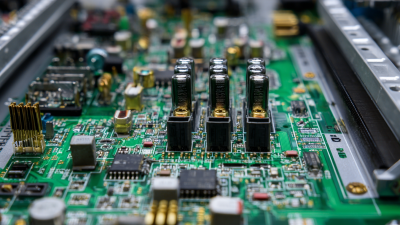

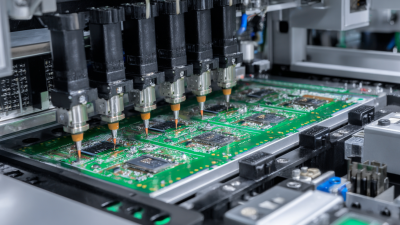

The importance of maintaining high-quality standards in printed circuit board (PCB) manufacturing cannot be overstated, as even minor defects can lead to significant failures in electronic devices. One crucial step in ensuring that PCBs meet stringent quality requirements is the effective inspection of solder paste application. This is where the Solder Paste Inspection Machine comes into play.

These advanced machines are designed to significantly enhance the quality control processes by providing accurate and timely assessments of solder paste deposits on circuit boards. By identifying potential issues such as insufficient or excessive paste application, these machines help manufacturers reduce the risk of defects, improve assembly yield, and ultimately increase product reliability.

As technology continues to evolve, the sophistication of Solder Paste Inspection Machines is expected to grow, addressing the increasing demands of modern electronic manufacturing and fostering a future where PCB quality control is more efficient and effective than ever before.

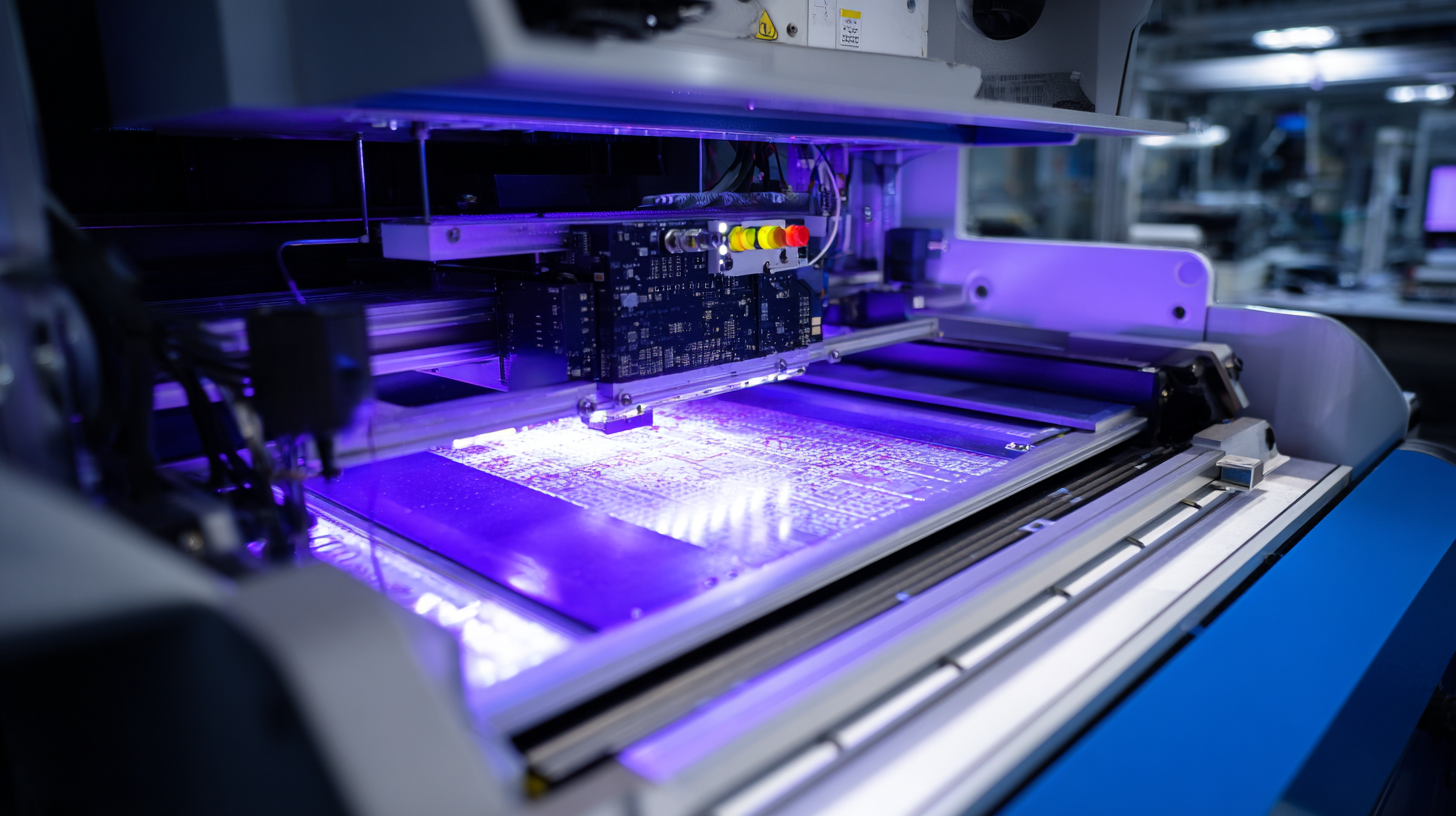

The integration of AI and machine learning technology into solder paste inspection machines is poised to revolutionize quality control in PCB manufacturing. Traditional inspection methods often rely on manual processes, which can be time-consuming and prone to human error. By employing advanced algorithms, these machines can quickly analyze data from inspections, learn from each pass, and adapt their processes accordingly. This capability not only increases the speed and accuracy of inspections but also significantly reduces the likelihood of defects slipping through the cracks.

Moreover, AI-driven solder paste inspection allows for real-time monitoring and feedback during the production process. Machine learning models can identify patterns and trends in the data, providing invaluable insights for engineers to optimize production lines. This proactive approach not only enhances product quality but also minimizes waste and lowers costs associated with rework. As the technology advances, we can expect to see even more sophisticated systems that can predict potential issues before they arise, ensuring that PCB production meets the highest standards of excellence.

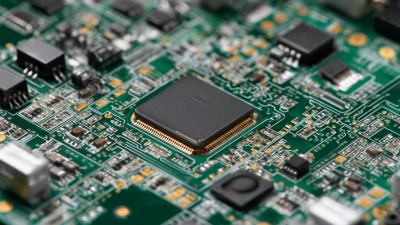

In the rapidly evolving landscape of electronics manufacturing, the importance of solder paste inspection (SPI) machines cannot be overstated. These machines play a critical role in enhancing PCB quality control by ensuring that the solder paste application meets the required specifications. According to a report by MarketsandMarkets, the global SPI market is projected to grow from USD 360 million in 2020 to USD 617 million by 2025, reflecting the increasing need for precision in assembly processes.

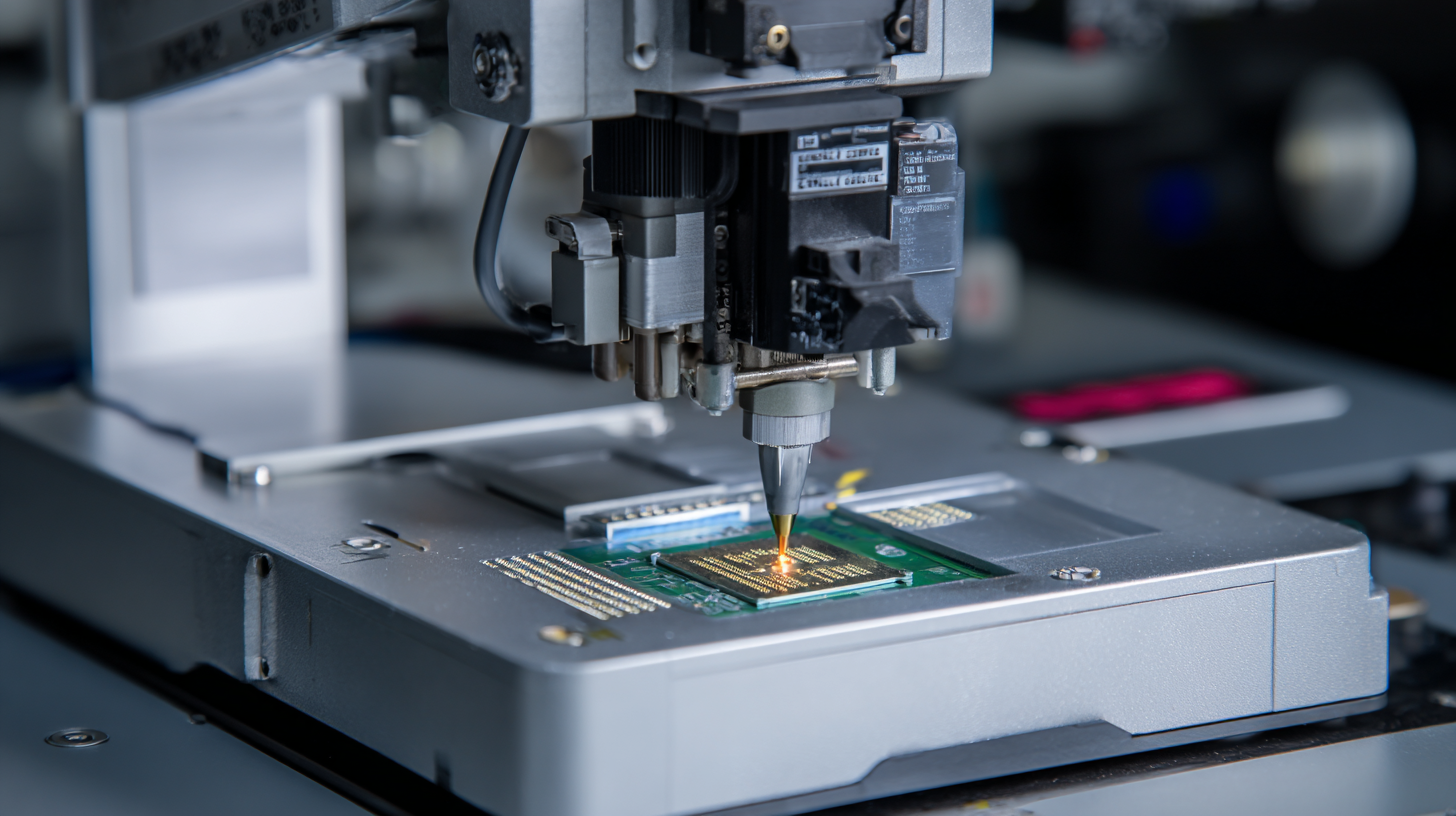

Modern solder paste inspection machines come with a range of key features that improve their efficiency and effectiveness. High-resolution imaging systems allow for detailed inspection of solder paste volumes, shapes, and placements, enabling detection of even the slightest deviations. Additionally, advanced software algorithms equipped with artificial intelligence can analyze the collected data in real time, ensuring prompt corrective actions are taken. Reports indicate that manufacturers employing state-of-the-art SPI technology can reduce misalignment issues by up to 70%, significantly enhancing overall production yield and reducing costly rework. With such advancements, investing in the right SPI technology is essential for future-proofing PCB manufacturing operations.

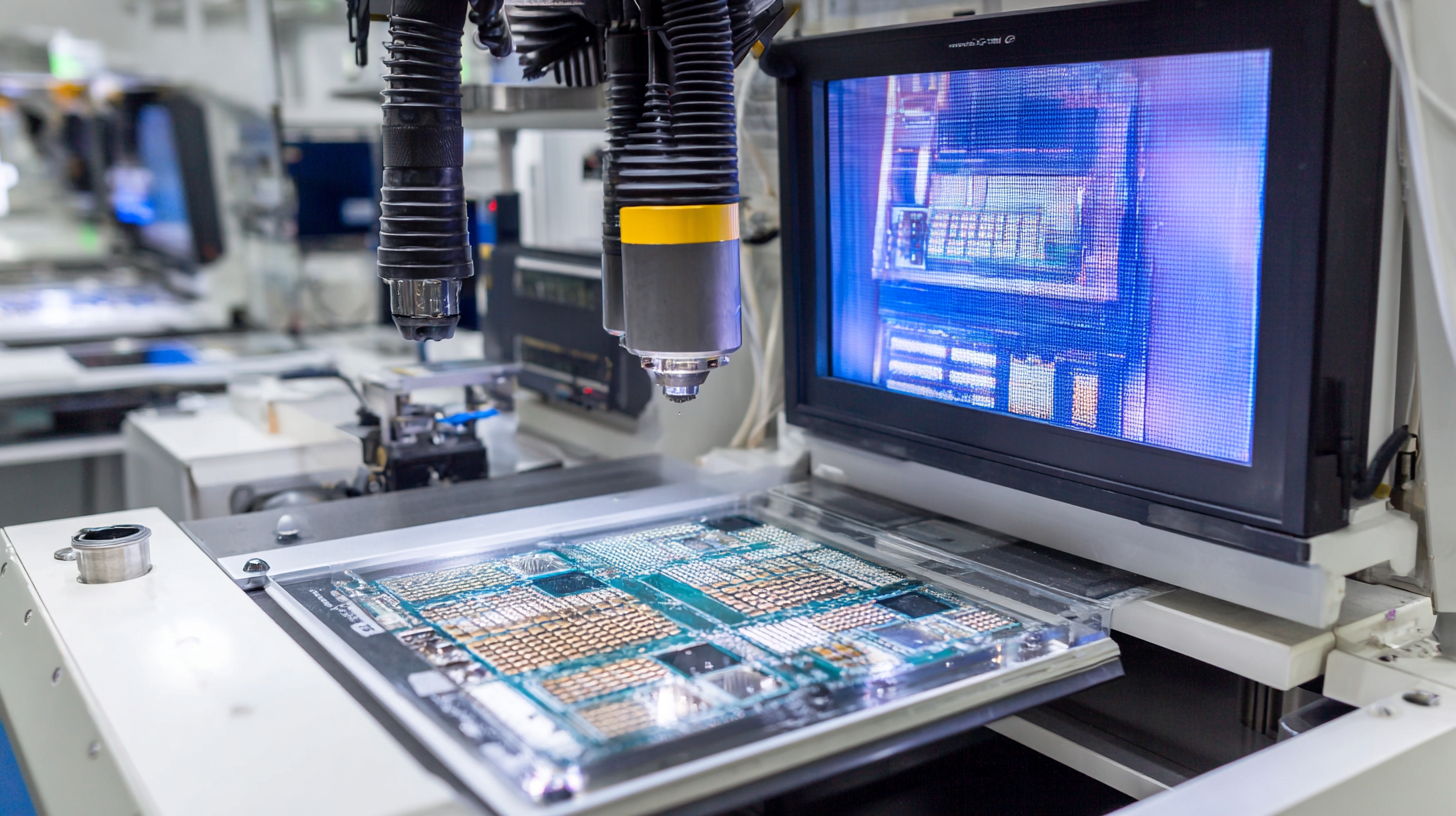

The integration of real-time data analysis into solder paste inspection machines represents a significant advancement in PCB quality control. By harnessing the power of AI and machine learning, manufacturers can swiftly process vast amounts of inspection data, allowing for instantaneous decision-making during the production cycle. According to industry reports, companies that implement real-time data analysis can improve their defect detection rates by up to 30%, significantly reducing costs associated with rework and material wastage.

Moreover, adopting advanced visual inspection systems like those based on NVIDIA technology can further enhance quality control efforts. These systems not only automate the inspection process but also utilize sophisticated algorithms to identify defects that may be invisible to the naked eye. A recent study highlighted that manufacturers deploying such technologies have experienced a noticeable increase in production efficiency, with some reporting up to 40% improvements in throughput.

As the electronics manufacturing landscape continues to evolve, the emphasis on real-time analysis and AI-driven tools will undoubtedly shape the future of quality assurance processes, prompting businesses to adapt and innovate.

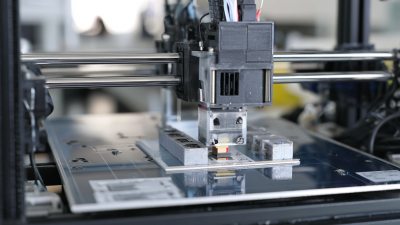

To maximize the efficiency of solder paste inspection systems, it is crucial to implement a series of best practices tailored to the unique requirements of each production line. First, ensuring optimal placement and calibration of the inspection machines can significantly enhance accuracy and throughput. Regular maintenance, combined with real-time monitoring of machine alignment, helps prevent discrepancies that could compromise the inspection process.

Furthermore, integrating advanced data analytics into the inspection workflow enables operators to identify patterns and trends in solder paste application quality. This information can lead to proactive adjustments in real time, minimizing potential defects before they escalate. Training personnel to effectively interpret inspection results and utilize this data is equally vital. By fostering a culture of continuous improvement, manufacturers can not only streamline their inspection processes but also drive overall product quality forward.

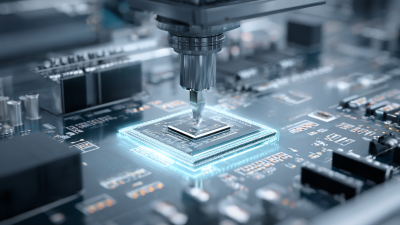

The future of solder paste inspection (SPI) technology in PCB manufacturing is poised for significant advancements, driven by the increasing complexity of electronic components and the demand for high-quality electrical connections. According to recent industry reports, the Europe SMT inspection equipment market is expected to witness a growth rate of over 7% CAGR due to the rising implementation of automated optical inspection systems, solder paste inspection, and automated X-ray techniques. This growth underscores the critical role that SPI systems play in ensuring manufacturing precision, significantly impacting yield rates and overall production efficiency.

Modern solder paste inspection systems utilize advanced imaging technologies to accurately measure the volume and alignment of solder on pads before component placement. This is crucial not only for preventing defects in the solder joints but also for enabling manufacturers to adapt to the miniaturization trend in electronics. Reports indicate that automated solder paste inspection can reduce the rate of defects by up to 90%, presenting manufacturers with an opportunity to enhance yield and reduce rework costs. As the industry moves toward more automated and intelligent inspection solutions, the alignment of SPI technology with artificial intelligence and machine learning capabilities will further enhance the detection of potential issues, establishing a new standard for quality control in PCB manufacturing.