-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

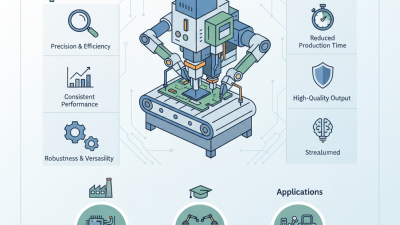

In the fast-evolving world of electronics manufacturing, choosing the right Solder Paste Printer is crucial. According to Dr. Emily Chen, an expert in the SMT industry, "The precision of a solder paste printer affects the entire assembly process." Her insight highlights the importance of careful selection.

When you select a Solder Paste Printer, consider various factors. Look beyond just the price. Reliability and consistency can greatly impact production. Consider the machine's ability to handle different paste types. This could be critical for your projects. Take the time to evaluate all features.

Every detail matters in the soldering process. A poor choice can lead to defects. This is a challenge faced by many companies. Sometimes, we overlook the little things. Be prepared to reassess your options. A good decision today can save trouble tomorrow.

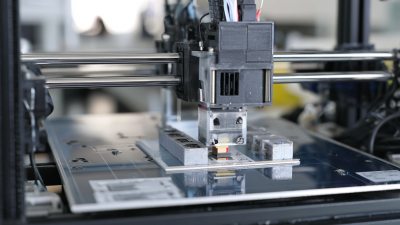

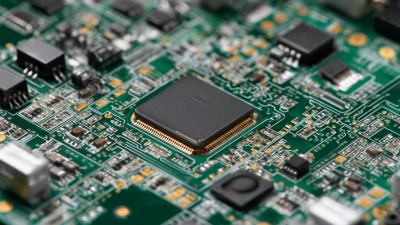

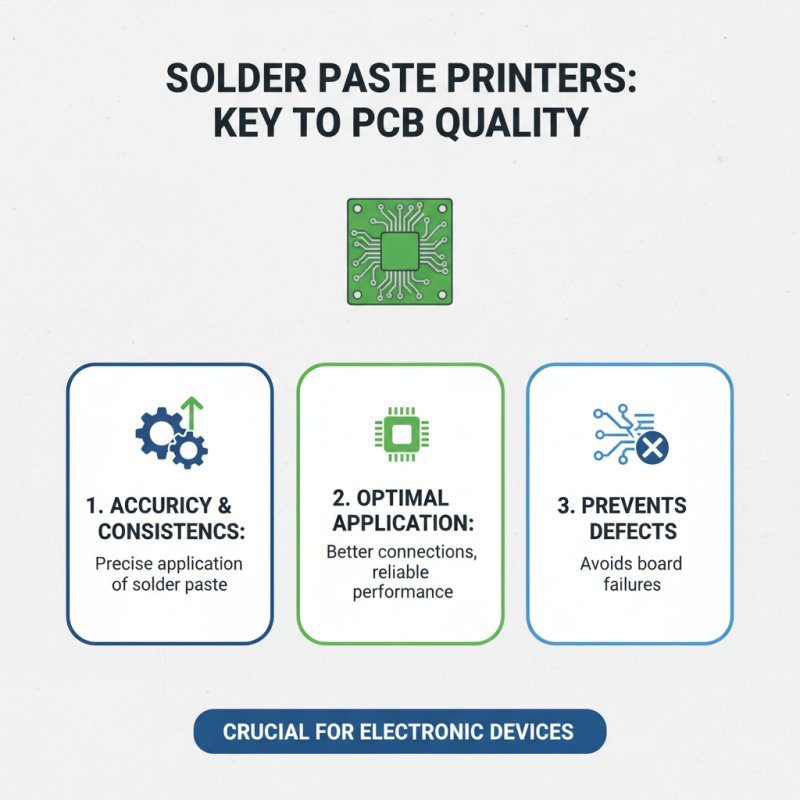

In the realm of PCB assembly, solder paste printers play a pivotal role. They ensure that solder paste is applied accurately and consistently, which is crucial for the quality of electronic devices. An optimal application leads to better connections and reliable performance. Inadequate solder paste can result in defects, which can compromise the entire board.

When choosing a solder paste printer, consider the following tips. First, assess the printer’s precision. A printer's ability to create fine patterns can greatly affect the outcome. Look for models that can handle different paste viscosities. Mixing the correct type of solder paste is essential for effective printing.

Additionally, evaluate the ease of use. An intuitive interface can save time and reduce errors. Without proper training, operators may struggle with complex machines. Understand how different printers manage cleanup and maintenance. A cumbersome process may lead to delays in production. Remember, a printer that is hard to clean can impact overall efficiency.

When selecting a solder paste printer, several key features can significantly impact your printing accuracy and efficiency. One of the most important aspects is the printer's alignment system. Precise alignment ensures that the solder paste is applied exactly where it is needed on the PCB. A misalignment of just 0.1mm can lead to component failures.

Another crucial feature to consider is the stencil clamping mechanism. A reliable clamping system holds the stencil securely in place, preventing shifts during the printing process. This stability is vital since studies indicate that a mere 10% error in paste deposition can reduce the reliability of the entire assembly. Look for printers that offer adjustable tension settings, allowing for flexibility based on different stencil materials.

Additionally, the print head design plays a significant role in paste transfer efficiency. A well-designed print head can enhance paste transfer rates, reducing the likelihood of print defects. Industry reports highlight that around 30% of defects in electronic assemblies arise from poor solder paste application. Therefore, investing in a printer with advanced print head technology is essential for maintaining high-quality production standards.

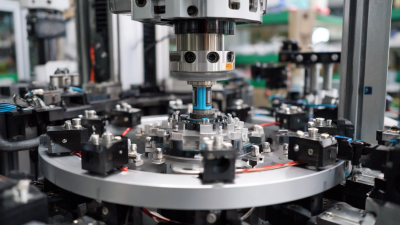

When selecting a solder paste printer, speed and accuracy are crucial. A faster printer can increase production rates. However, speed should not compromise the quality of the solder paste application. Precision plays a vital role in ensuring that solder paste adheres correctly to the circuit board. If the printer is too quick, defects may occur, leading to expensive rework.

The ideal printer balances speed and accuracy. For instance, slower printing at times can result in better paste placement. An operator might notice misalignment or insufficient paste application with rapid printing. These issues can lead to reduced yield and prolonged assembly time. It's essential to assess the specific needs of the production line.

In choosing a solder paste printer, consider the impact of both features on overall performance. Testing out different speeds in real-world conditions can reveal unexpected problems. A printer that seems perfect on paper might falter in practice. Continuous evaluation and adjustment are key to achieving optimal results on the production floor.

| Tip | Description | Printing Speed (mm/s) | Accuracy (% Variation) | Recommended for |

|---|---|---|---|---|

| 1. Assess Printing Speed | Choose a printer with suitable speed based on production volume. | 100 | ±5% | High Volume Production |

| 2. Evaluate Print Accuracy | Focus on printers that provide high precision for detailed work. | 80 | ±3% | Prototype Development |

| 3. Check Paste Dispensing Consistency | Ensure uniform distribution to avoid defects in soldering. | 90 | ±4% | All Applications |

| 4. Consider Maintenance Needs | Select a printer that is easy to maintain for long-term reliability. | 120 | ±6% | Continuous Production |

| 5. Analyze Feed Mechanism | Review how the solder paste is fed to ensure even application. | 110 | ±2% | Specialized Boards |

When selecting a solder paste printer, compatibility with different solder paste types is crucial. Each type of solder paste has its unique properties. Some are designed for fine pitch applications, while others work better for coarse pitches. This variation can affect how well the printer performs during the application process.

It's essential to consider the viscosity of the solder paste. Higher viscosity pastes require more pressure and may affect the printing speed. Similarly, the particle size can influence the final print quality. Larger particles may lead to blockages. Testing a few types of solder pastes can reveal which one fits your printer's design best.

Additionally, the drying time of the paste should be examined. Some pastes dry quickly, which may not be suitable for high-speed production lines. Experimenting with different pastes may lead to unintended challenges. Finding the right balance can feel overwhelming, but it’s important to embrace this trial-and-error phase. Ultimately, the right match can enhance efficiency and product quality significantly.

When considering a solder paste printer, cost and quality often clash. It's crucial to assess how each factor affects your production. Investing in a high-quality machine may appear costly upfront. However, this decision can lead to better consistency and less waste in the long run. The right investment can significantly impact your efficiency.

Evaluate your specific needs. Are you working on small runs or mass production? A more expensive printer might be better if quality is vital. But if you're doing basic jobs, a budget-friendly option might suffice. Don't overlook the technical aspects, such as printing speed and precision. These characteristics can directly influence your output quality.

Tip: Always do thorough research before making a decision. Reach out to peers in the industry for recommendations. Finding a balance between cost and quality is tricky but necessary. Reflect on your production goals. This will guide you toward a printer that meets your needs while managing your budget effectively. Another tip: consider the total cost of ownership. Maintenance costs can add up. A cheaper printer might require frequent repairs or part replacements.