-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

The landscape of electronics manufacturing is rapidly evolving, driven by advancements in technology and an increasing demand for efficiency and precision. According to a recent report by MarketsandMarkets, the global surface mount technology (SMT) market is projected to reach USD 12.93 billion by 2026, growing at a Compound Annual Growth Rate (CAGR) of 4.85% from 2021 to 2026. This growth is largely attributed to the surge in electronics production and the need for accurate and reliable manufacturing processes. In this context, Fuji SMT Machine technology plays a pivotal role, offering innovative solutions designed to meet the complex demands of modern electronics assembly.

The capabilities of Fuji SMT Machines are significant; they provide high-speed placement, enhanced flexibility, and superior quality control, aligning perfectly with the industry's push towards automation and smart manufacturing. With the advent of Industry 4.0, manufacturers are increasingly incorporating advanced robotics and artificial intelligence into their production lines, enabling them to optimize processes and reduce downtime. A report by Technavio forecasts that the global industrial automation market, which includes SMT technology, will grow by over USD 130 billion between now and 2024. As such, the adoption of Fuji SMT Machines is not merely an option but a necessity for manufacturers aiming to stay competitive in this fast-paced environment.

In conclusion, as the electronics manufacturing sector continues to innovate, Fuji SMT Machine technology stands out as a beacon of efficiency and reliability, positioning itself at the forefront of this transformative journey.

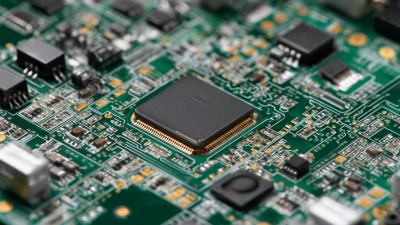

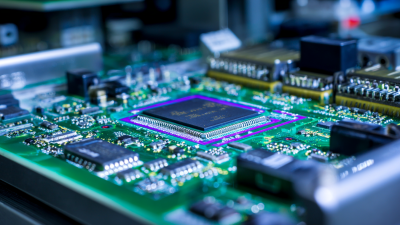

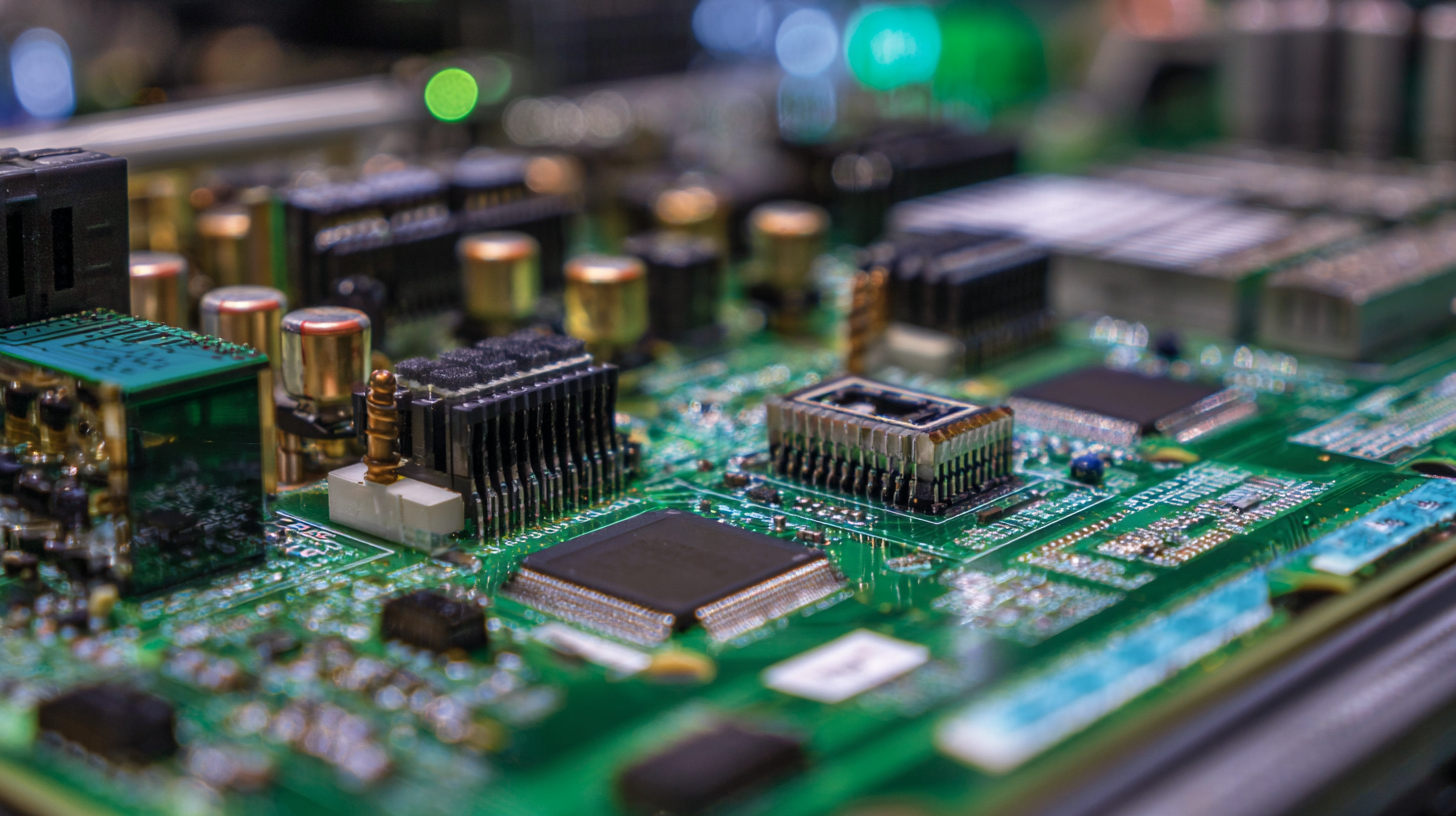

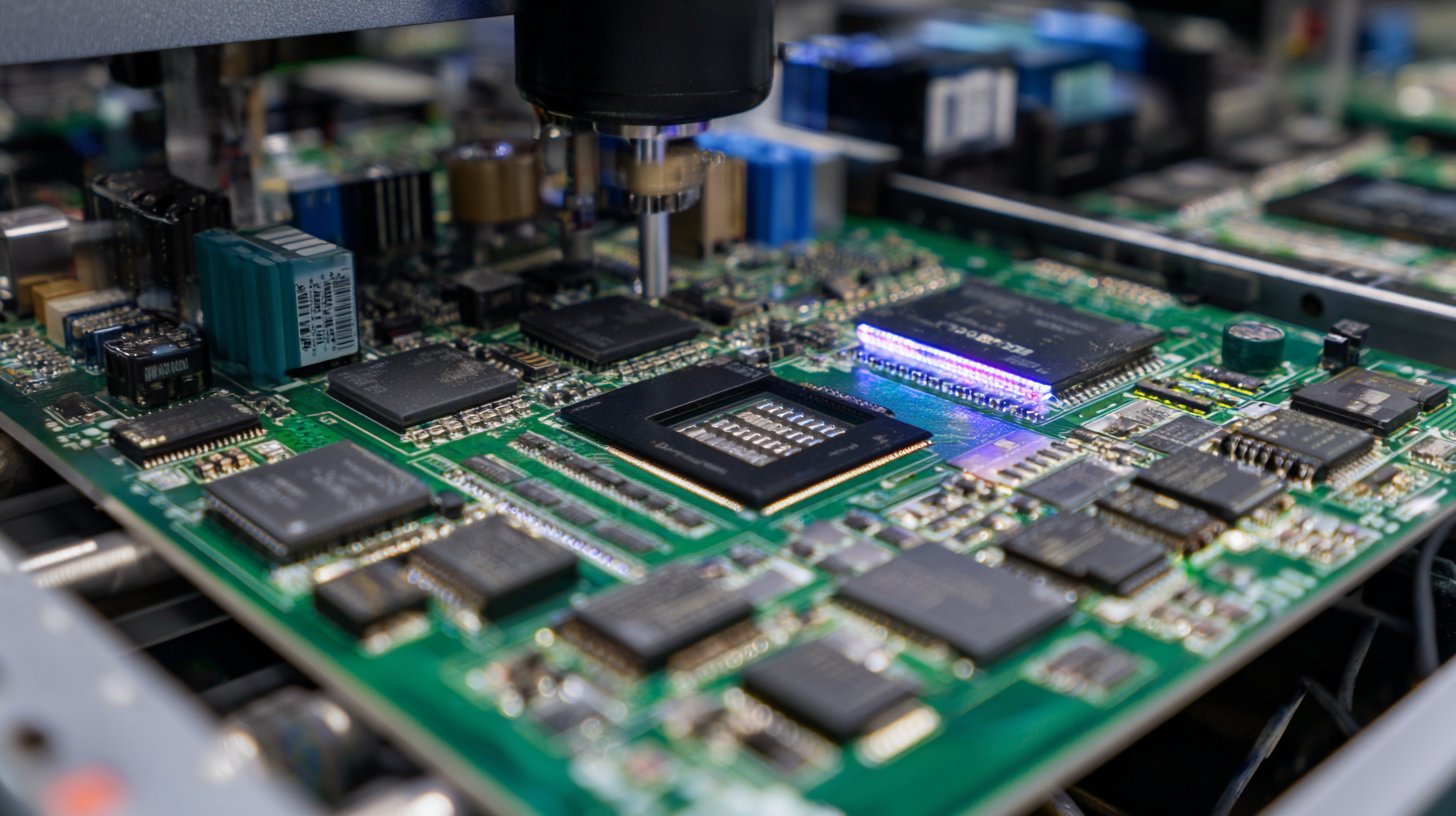

Fuji SMT machine technology has revolutionized the electronics manufacturing landscape, providing enhanced efficiency and precision. At its core, Surface Mount Technology (SMT) allows for the assembly of electronic components directly onto the surface of printed circuit boards (PCBs). This process has become essential in modern manufacturing due to its ability to support compact design and high-density component placement, leading to significant space and cost savings for manufacturers.

Tips: When considering SMT equipment, assess the compatibility of the machine with your production line and future upgrades. Understanding the dimensions of your components and the necessary soldering techniques can also alleviate potential issues, ensuring smoother operations.

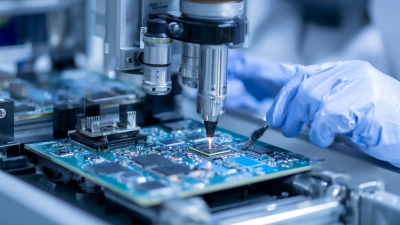

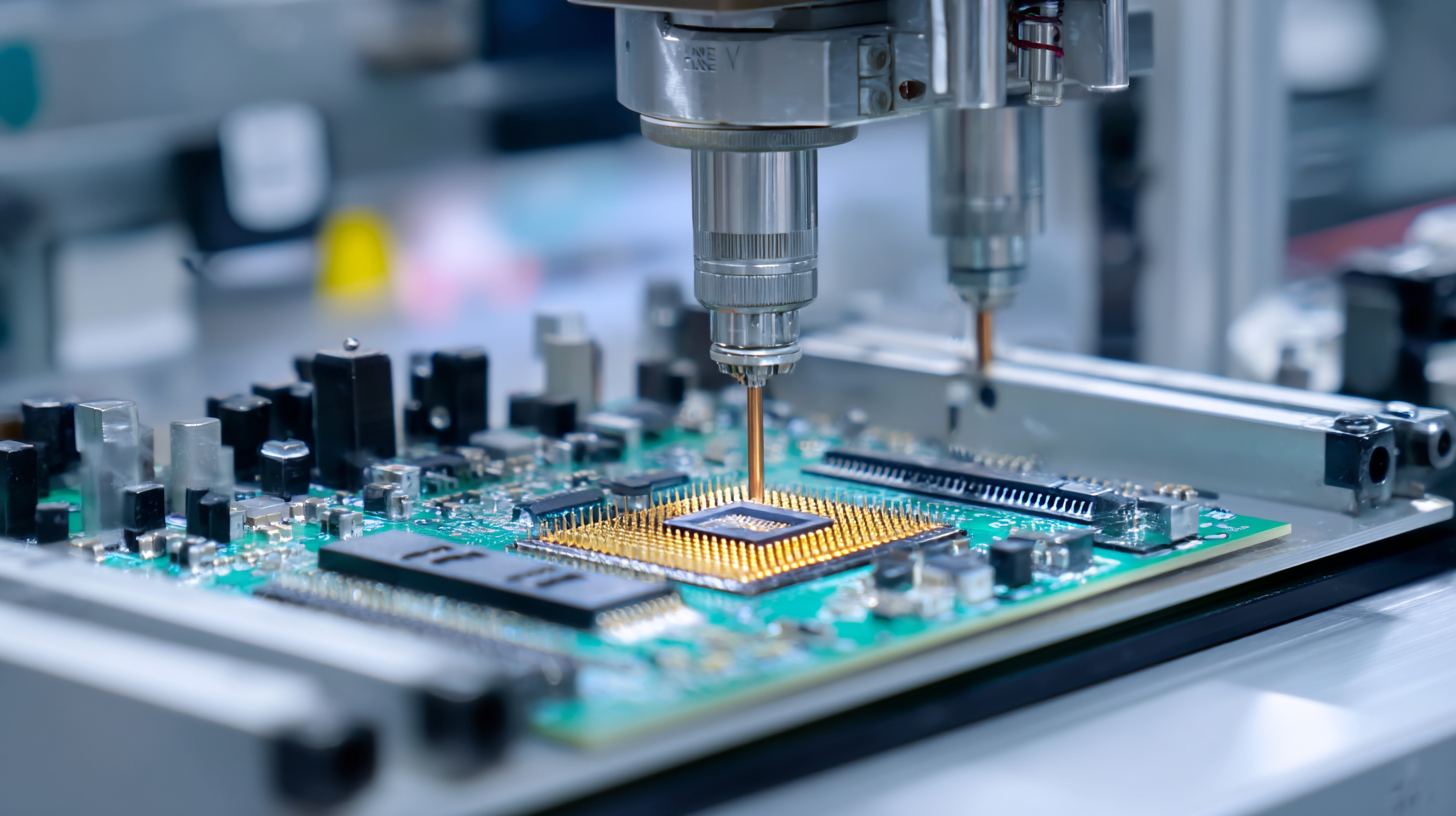

The advantages of Fuji SMT machines lie in their automation capabilities, which minimize human error and streamline the assembly process. These machines come equipped with advanced vision systems and software that enhance placement accuracy, drastically reducing the incidence of defects. Moreover, their modular nature allows for easy integration into existing workflows, making it simpler for manufacturers to scale operations to meet changing demands.

Tips: Regular maintenance and updates are crucial to keeping Fuji SMT machines running at peak performance. Training staff on the latest technologies and troubleshooting techniques can further enhance efficiency and product quality in your electronics manufacturing process.

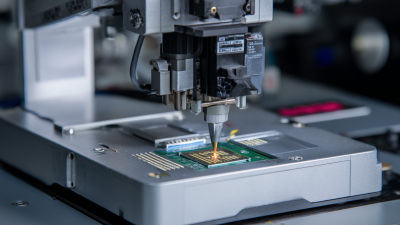

The integration of Fuji SMT machines into electronics manufacturing

offers a multitude of benefits that can significantly enhance production efficiency and product quality. According to a recent report by IPC, the global electronics manufacturing services (EMS) market is projected to reach

$523 billion by 2025, demonstrating the critical role that advanced machinery plays in keeping pace with growing demand. Fuji's innovative technologies, particularly their

high-speed placement and automated setup features, allow manufacturers to reduce cycle times and increase output.

Moreover, the precision and reliability of Fuji SMT machines lead to lower defect rates and improved yield. A study by SEMI indicates that manufacturers utilizing high-precision equipment can achieve defect rates as low as

0.1%. This level of accuracy not only bolsters product quality but also minimizes waste, aligning with sustainability goals that are increasingly important in the industry.

By investing in Fuji SMT technology, companies can not only enhance their current capabilities but also

future-proof their operations in a rapidly evolving market landscape.

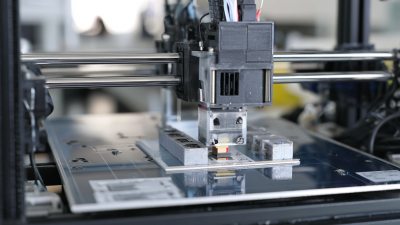

Implementing Fuji SMT technology in your facility is a systematic process that can significantly enhance your electronics manufacturing operations. The first step is to assess your current production setup. This involves understanding your existing processes, identifying bottlenecks, and determining how Fuji SMT machines can address these inefficiencies. Conducting a thorough analysis will also help in defining the necessary specifications for the new equipment aligned with your production goals.

Once the assessment is complete, the next step is to select the right Fuji SMT machines tailored to your operational needs. Engage with Fuji’s experts to gain insight into their latest technologies and solutions that match your requirements. After procurement, it’s crucial to plan the installation carefully, ensuring minimal disruption to ongoing operations.

Once the assessment is complete, the next step is to select the right Fuji SMT machines tailored to your operational needs. Engage with Fuji’s experts to gain insight into their latest technologies and solutions that match your requirements. After procurement, it’s crucial to plan the installation carefully, ensuring minimal disruption to ongoing operations.

Training your staff on the new technology is equally important; providing comprehensive training sessions will empower your team to utilize the machines effectively and maximize their potential. By following these steps, you can seamlessly implement Fuji SMT technology into your facility, paving the way for improved efficiency and competitiveness in the electronics market.

The future of electronics manufacturing is poised for transformation through the integration of Fuji SMT technologies. As industries continue to demand faster production cycles and improved quality, Fuji's innovative solutions are set to redefine standards. The emergence of smart factories, driven by automation and the Internet of Things (IoT), will allow for real-time monitoring and optimization of production processes. Fuji SMT machines, known for their precision and efficiency, play a crucial role in enhancing overall productivity and minimizing waste in electronic assembly lines.

Moreover, sustainability will increasingly influence manufacturing practices. Fuji’s commitment to eco-friendly technology not only addresses environmental concerns but also caters to consumer demands for greener products. The incorporation of advanced materials and energy-efficient processes will become a focal point in the development of new electronics. As manufacturers adopt Fuji SMT technologies, they will be better equipped to respond to market changes, driving innovation while maintaining a sustainable approach. Through these advancements, Fuji is paving the way for a more efficient, responsive, and environmentally-conscious electronics manufacturing landscape.

| Dimension | Value | Future Trend |

|---|---|---|

| Automation Level | 95% | Increased automation leading to higher efficiency |

| Production Speed | 20,000 components/hour | Optimized high-speed manufacturing processes |

| Yield Rate | 98% | Improved quality assurance measures |

| Employee Skill Requirement | Advanced | Need for skilled technicians to operate complex machinery |

| Environmental Compliance | 100% | Stricter regulations and eco-friendly practices |

| Machine Learning Integration | Yes | Utilization of AI for predictive maintenance and optimization |

Adopting Fuji SMT machines in electronics manufacturing presents several common challenges that organizations must navigate to fully leverage the benefits of this advanced technology. One significant challenge is the integration of these machines into existing workflows. As businesses increasingly embrace digital transformation, simply introducing new technology isn't enough; it requires a thoughtful approach to training and adapting processes. Overcoming resistance from employees who are accustomed to traditional methods is essential. Companies must prioritize continuous education and support to ensure that staff are comfortable and proficient in using enhanced machines.

Moreover, supply chain disruptions can hinder the seamless transition to Fuji SMT machines. The current landscape of electronics manufacturing has highlighted the importance of robust supply chains, making it crucial for organizations to develop strategies that mitigate risks associated with material shortages or delays. Establishing strong partnerships with suppliers and implementing flexible inventory management systems can help address these concerns. By proactively tackling these challenges, companies can ensure that they successfully adopt Fuji SMT technology and improve their manufacturing efficiency in a rapidly evolving industry.