-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In the fast-evolving world of electronics manufacturing, choosing the right BGA Rework Station is crucial for ensuring high-quality repairs and maintenances. As we approach 2025, the demand for efficient and reliable rework solutions has never been greater. According to Dr. Steven Martinez, a leading expert in electronic assembly technology, "Selecting the right BGA Rework Station can significantly enhance productivity and reduce operational risks in electronic repairs." His insights shed light on the importance of not only understanding the technical specifications but also considering the long-term benefits of investing in a high-quality rework station.

In this ultimate guide, we will explore the top models available in 2025, highlighting the features and innovations that set them apart in the market. From advanced temperature control systems to user-friendly interfaces, the range of options can be overwhelming for both seasoned technicians and newcomers alike. By taking a strategic approach to this selection process, operators can tailor their BGA rework capabilities to meet specific production needs while ensuring superior outcomes.

With a focus on efficiency, compatibility, and reliability, our guide aims to equip you with the knowledge necessary to make an informed decision. By understanding the trends and technological advancements in BGA Rework Stations, you will be well-prepared to invest wisely and elevate your rework processes to new heights in the coming year.

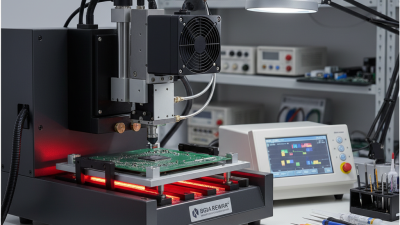

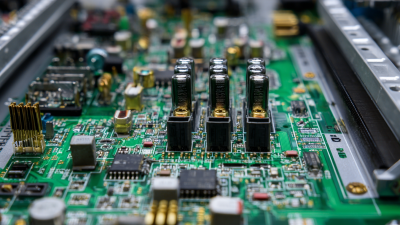

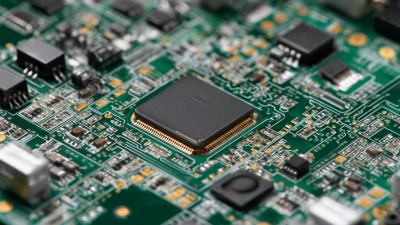

BGA rework stations are specialized tools designed for the repair and reinstallation of Ball Grid Array (BGA) components on printed circuit boards (PCBs). These components, which are commonly found in modern electronics, feature an array of solder balls that create electrical connections to the PCB. The primary purpose of a BGA rework station is to facilitate the removal and replacement of BGAs without causing damage to the surrounding components or the board itself. This process is essential for maintaining the integrity and functionality of electronic devices, especially as they become more compact and complex.

A BGA rework station typically combines several critical features, including precise temperature control, innovative soldering techniques, and advanced optical systems for alignment and inspection. The station's design allows for consistent heating, ensuring that solder joints are melted and reflowed properly during the repair process. Additionally, many stations include features such as vacuum pick-up tools for handling BGAs and under-heating plates to prevent thermal shock to the PCB. Ultimately, understanding the intricacies and functionality of BGA rework stations is vital for professionals seeking reliable and efficient solutions for electronics repair in a rapidly evolving industry.

When selecting a BGA rework station for 2025, it's essential to consider several key features that can significantly influence the performance and efficiency of your rework processes. One of the primary aspects is the heating technology used in the station. Advanced models increasingly adopt infrared or hot air methods to achieve uniform heating across BGAs, minimizing the risk of thermal stress and damage to sensitive components.

According to a report by IPC, 67% of repair professionals cite inadequate heating as a leading cause of failure in BGA rework, underscoring the importance of precise temperature control and advanced heating techniques.

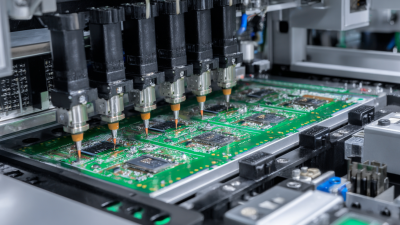

Another crucial feature is the system's capability for real-time monitoring and adjustability. Many modern BGA rework stations are equipped with digital displays and software that allow for precise adjustment of temperature profiles and soldering durations. Recent market analyses indicate that rework stations with built-in sensor technology have shown a 40% increase in operational efficiency, as they facilitate instant feedback and adjustments during the rework process. Additionally, ease of use and ergonomic design are vital, enabling technicians to work efficiently while minimizing fatigue, which can lead to errors.

Lastly, consider the versatility of the rework station. A multifunctional unit that can handle various component sizes, solder types, and rework techniques will provide better value and adaptability for different projects. Industry reports emphasize that stations with modular designs can enhance workflow efficiencies by up to 30%, as they streamline the transition between different rework tasks. By prioritizing these features, professionals can ensure they select a BGA rework station that meets the demands of an evolving industry.

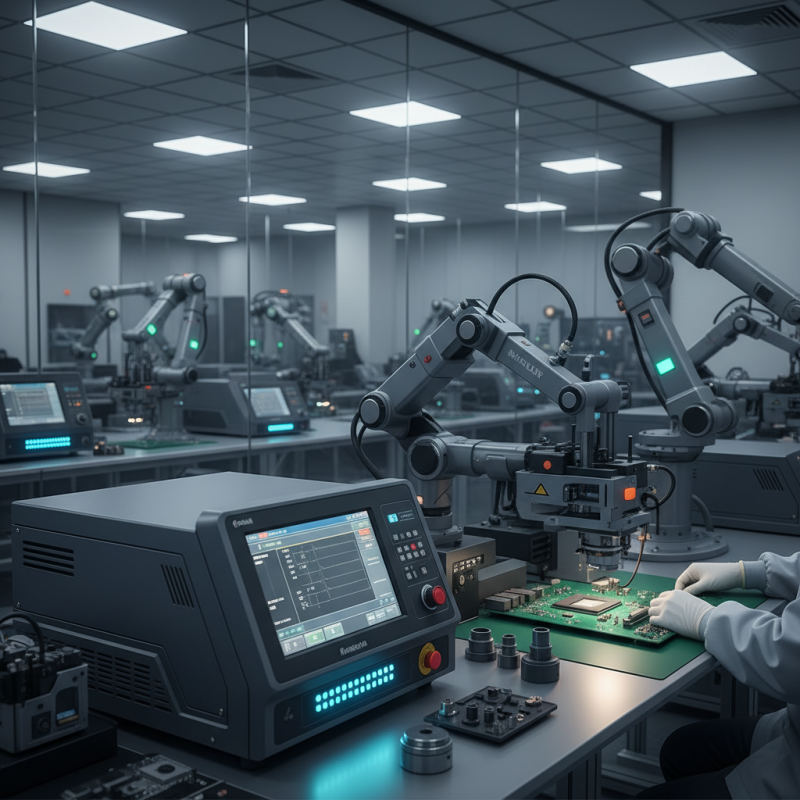

When it comes to selecting a BGA rework station in 2025, understanding the variety of models available is crucial for making an informed decision. The top models are designed to accommodate the latest technological advancements and provide enhanced features that streamline the rework process. These state-of-the-art stations often come equipped with advanced thermal management systems, precise temperature controls, and reliable software interfaces that simplify operation for both experienced technicians and newcomers.

Additionally, the best BGA rework station options boast designs that prioritize user comfort and efficiency. Features like ergonomic workspaces, customizable settings, and robust safety mechanisms allow operators to focus on quality results rather than struggling with equipment limitations. As technology evolves, many of these models reflect a focus on sustainability, incorporating energy-efficient components that align with growing environmental concerns.

This comprehensive examination of available options is essential for professionals aiming to maintain a competitive edge in the rapidly-changing electronics repair industry.

When selecting a BGA rework station, understanding the balance between price and performance is crucial for making an informed decision. The market offers a wide range of options, and while affordability is appealing, it's essential to assess whether a lower price correlates with reduced functionality or durability. A cheap station might lack the precision, thermal control, or features that are critical for high-quality repairs, potentially leading to further issues and costs in the long run.

When delving into the specifics, consider key performance indicators such as temperature stability, heating technology, and ease of use. A station that may be slightly more expensive could provide better thermal profiling and faster reflow times, which ultimately saves time and enhances efficiency.

**Tips:** Before making a purchase, research user reviews and ratings to gauge real-world performance. Additionally, look for models that offer a good warranty and customer support, as these are indicators of durability and service reliability. Investing time in comparative analysis can streamline your decision-making process, ensuring you choose a BGA rework station that offers the best value for your specific repair needs.

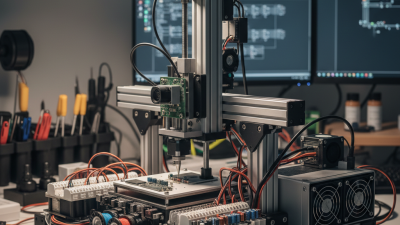

As we look ahead to 2025, the landscape of BGA rework technology is poised for significant evolution, driven by advanced innovations and an increasing demand for precision in electronics manufacturing. One of the key trends is the integration of automation within rework stations, allowing for more efficient soldering and desoldering processes. Automated equipment will enable technicians to achieve high levels of precision while minimizing the risk of damage to sensitive components. This shift not only enhances operational efficiency but also leads to improved quality assurance across production lines.

Another notable trend is the development of enhanced thermal management systems. Future BGA rework stations are expected to incorporate advanced temperature control technologies that provide greater stability and accuracy during the reworking process. This is particularly crucial as electronic components become smaller and more complex, requiring meticulous handling to avoid overheating or thermal shock. Additionally, the introduction of smart technology, featuring real-time data analytics and machine learning, will enable technicians to monitor and optimize their workflows, thus reducing downtime and increasing productivity.

Lastly, as sustainability becomes a priority in the electronics industry, BGA rework technology will likely evolve to include eco-friendly practices. The use of low-emission materials and energy-efficient designs will not only reduce environmental impact but also align with the growing emphasis on corporate responsibility in manufacturing. As these trends unfold, the BGA rework stations of 2025 will reflect a balance of high performance, precision, and sustainability, setting new benchmarks for the future of electronics repair and assembly.