-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

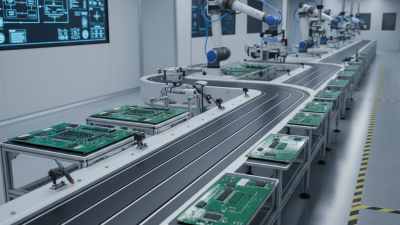

In the rapidly evolving world of electronics manufacturing, the efficiency of PCB assembly is paramount to meeting market demands and sustaining competitive advantage. At the heart of this efficiency lies the Pick And Place Machine PCB, a critical tool that automates the component placement process, enabling manufacturers to produce high-quality printed circuit boards with precision and speed. As technology advances, the capabilities of these machines have expanded, allowing for improved placement accuracy, faster cycle times, and greater flexibility in handling various component types.

This ultimate guide aims to provide a comprehensive overview of Pick And Place Machines for PCB assembly, shedding light on their functionalities, benefits, and considerations for selection. By understanding the key features and operational principles of these machines, manufacturers can make informed decisions that enhance their production workflows. Whether you are a seasoned expert or new to PCB assembly, this guide will equip you with the knowledge necessary to leverage Pick And Place Machines in maximizing efficiency and driving innovation in your production processes.

The pick and place machine is a pivotal component in the realm of PCB assembly, significantly impacting production efficiency and accuracy. At its core, this machine automates the placement of electronic components onto printed circuit boards (PCBs), considerably reducing the time taken for assembly compared to manual processes. According to a report from IPC (Institute of IPC), the adoption of automated assembly solutions, including pick and place machines, can increase productivity by up to 50% while minimizing defects to less than 1%.

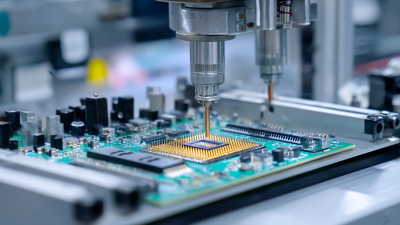

Understanding the basics of pick and place machines involves recognizing their operational mechanics, including vision systems, component handling, and placement speed. Modern machines utilize sophisticated camera systems that allow for precise component identification and alignment, which is crucial for high-density PCB designs. Furthermore, a market research forecast by MarketsandMarkets indicates a projected growth of the pick and place machine market at a CAGR of 7.2% through 2025, highlighting the industry's shift towards greater automation and efficiency in PCB manufacturing processes. This shift not only supports faster turnaround times but also helps manufacturers meet the rising demand for complex and miniaturized electronic devices.

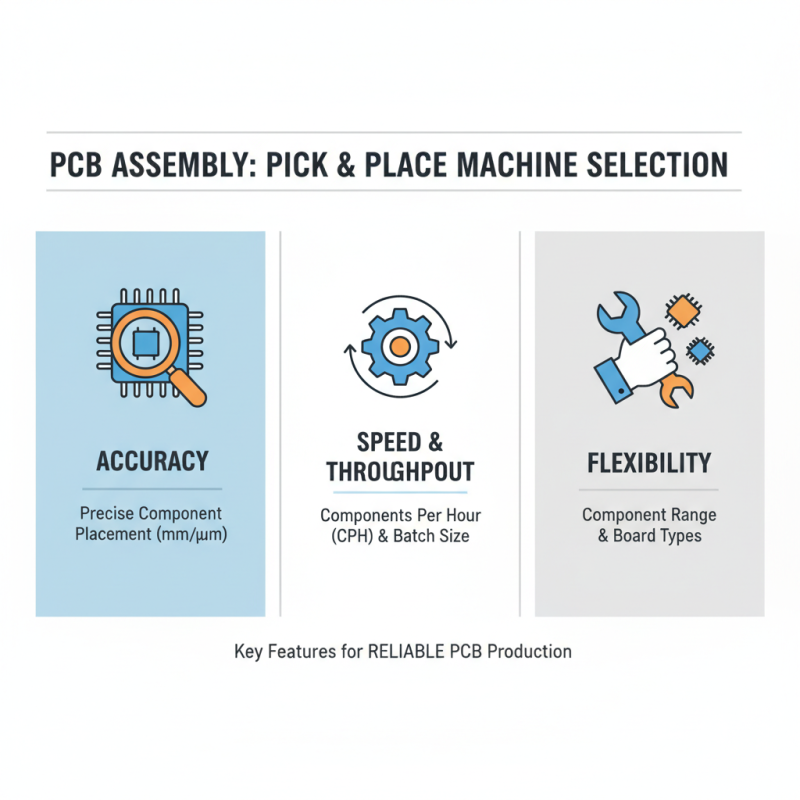

When selecting a pick and place machine for PCB assembly, several key features should be at the forefront of your decision-making process. First and foremost, accuracy is crucial. The ability of the machine to place components with minimal deviation is essential for ensuring the integrity of the final product. Manufacturers should look for machines that offer high precision placement capabilities, typically measured in millimeters and microns. This level of accuracy reduces the risk of assembly defects and enhances the overall reliability of the PCB.

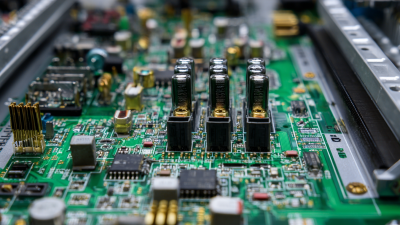

Another important feature to consider is the machine's speed and throughput. In a competitive manufacturing environment, efficiency can significantly impact production rates and cost-effectiveness. A high-speed pick and place machine can significantly improve workflow, allowing for the rapid completion of assembly projects without compromising quality. Additionally, consider the versatility of the machine in handling various component sizes and types. Flexibility in component handling ensures that the machine can adapt to different project requirements, making it a valuable asset in a dynamic production setting.

In the realm of PCB assembly, optimizing workflow is essential for enhancing productivity and ensuring high-quality output. The integration of pick and place technology significantly streamlines the assembly process, allowing for precise placement of components on circuit boards. This efficiency not only accelerates production rates but also reduces the likelihood of errors associated with manual assembly.

One key tip for maximizing the benefits of pick and place machines is to ensure proper setup and calibration. Regularly maintaining the equipment and adjusting parameters based on the specific components and PCBs being used can lead to improved accuracy and faster assembly times. Additionally, organizing components in an accessible manner can help operators quickly load materials, minimizing downtime and enhancing workflow efficiency.

Another important consideration is the implementation of software solutions that integrate seamlessly with pick and place machines. Utilizing software that allows for real-time monitoring and data analysis not only helps in identifying bottlenecks but also provides insights for continuous improvement. Keeping track of production metrics can inform more strategic decision-making, leading to a streamlined assembly process that ultimately boosts overall productivity.

When utilizing pick and place machines for PCB assembly, various challenges can arise that may hinder efficiency and productivity. One of the most common issues is component misalignment. This problem can lead to faulty assembly, necessitating rework that adds time and costs. Ensuring that the machine settings are calibrated correctly and that components are organized in a way that minimizes picking errors is crucial in overcoming this challenge.

Another frequent challenge is managing different component sizes and types. This can complicate the pick and place process, leading to longer cycle times. To address this, operators should consider implementing automated vision systems that can adapt to varying components. Additionally, regular maintenance of the machine can help avoid mechanical issues that may arise from handling a diverse range of parts.

Tips for optimizing pick and place efficiency include conducting regular training sessions for operators, focusing on the nuances of machine operation and troubleshooting common issues. Investing in real-time monitoring tools can also provide insights into production bottlenecks, allowing for swift corrective measures. Lastly, using an organized approach to component storage can streamline the workflow, reducing time lost in searching for parts during assembly.

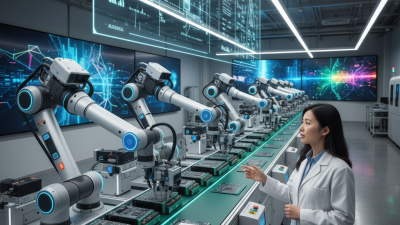

The field of PCB assembly is witnessing rapid evolution, particularly in the realm of pick and place machines. As technology advances, these machines are being designed to enhance assembly efficiency through automation, AI integration, and improved vision systems. Future trends indicate a shift towards more intelligent machines capable of real-time adjustments based on component availability and layout changes. This adaptability not only streamlines the assembly process but also reduces downtime, ultimately leading to increased productivity and cost savings.

Tips: One way to stay ahead in optimizing your pick and place operations is to invest in training for your operators. Familiarity with advanced features can lead to better utilization of machine capabilities, resulting in smoother workflows. Additionally, keep an eye on emerging technologies such as machine learning algorithms that can predict assembly issues before they arise, giving you a competitive edge.

Furthermore, the integration of IoT in pick and place machines allows for enhanced data collection and analysis. This connectivity facilitates predictive maintenance and performance monitoring, ensuring that machines operate at peak efficiency. Regular updates and maintenance checks on these systems will help prevent costly interruptions in your assembly line.

Tips: Consider scheduling routine audits of your production process and incorporate feedback loops to identify areas for improvement. This proactive approach not only maximizes efficiency but also drives innovation within your assembly operations.