-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In the rapidly evolving landscape of electronics manufacturing, SMT reflow technology has emerged as a critical element in optimizing PCB assembly processes. As the demand for more compact and complex circuit boards increases, manufacturers are constantly seeking innovative techniques to enhance production efficiency without compromising quality. This article delves into the latest advances in SMT reflow technology, highlighting crucial methodologies and tools that streamline the assembly process.

From advancements in oven design to improved temperature management strategies, each innovation plays a significant role in ensuring precise soldering and minimizing defects. By exploring these cutting-edge developments, businesses can leverage SMT reflow technology to achieve higher throughput, cost savings, and ultimately better performance in their electronic products.

Understanding how to implement these improvements effectively is essential for manufacturers aiming to stay competitive in today's fast-paced market.

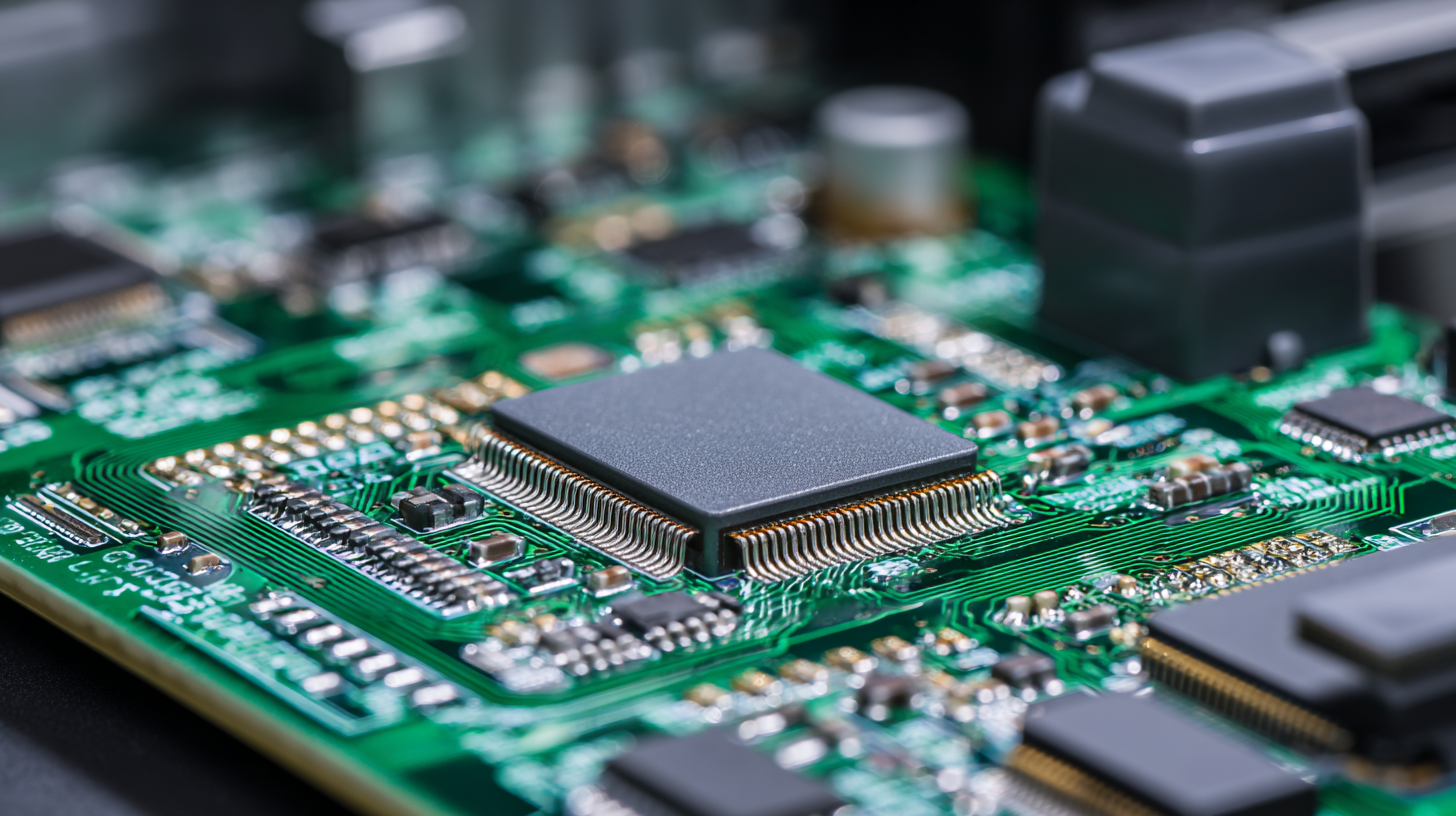

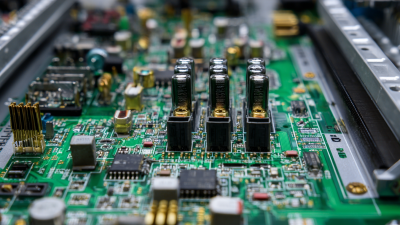

Surface Mount Technology (SMT) reflow is a crucial process in the assembly of printed circuit boards (PCBs), fundamentally altering how electronic components are mounted and soldered onto the boards. The reflow soldering process involves applying solder paste to the component pads, placing components on the paste, and then subjecting the assembly to a heating profile that melts the solder and forms reliable electrical connections. A deep understanding of this process is essential for ensuring optimal performance and reliability in electronic devices.

Several key principles underpin SMT reflow technology. The temperature profile is critical; it must be carefully controlled to achieve the ideal balance between heating rates and cooling times. Overheating can damage components, while inadequate heating might result in poor solder joints. Additionally, the type of solder paste used can greatly affect the outcome, influencing factors such as viscosity and melting point. As such, advancements in reflow technology focus not only on improving the efficiency of the equipment but also enhancing the quality of the materials used in the assembly process, ensuring that modern electronic devices meet the increasing demands for performance and miniaturization.

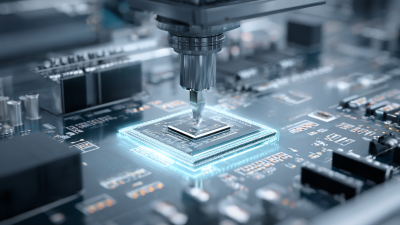

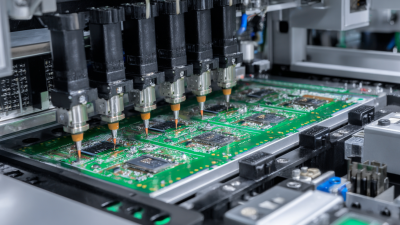

The field of PCB assembly has witnessed significant advancements, particularly in reflow oven technology, which plays a crucial role in enhancing the efficiency of surface-mount technology (SMT). Recent reports indicate that the implementation of advanced thermal profiling systems in reflow ovens can reduce cycle times by up to 30%. By utilizing sophisticated algorithms, these systems ensure optimal heat distribution, allowing for a more consistent soldering process that reduces defects and improves overall solder joint quality.

Furthermore, the integration of IoT (Internet of Things) capabilities into reflow ovens has transformed the manufacturing landscape. According to a recent industry analysis by IPC, connected ovens can provide real-time data on temperature profiles and energy consumption, offering manufacturers insights into process optimization. This connectivity leads to increased automation and less manual intervention, streamlining the production line and enhancing efficiency by nearly 20% compared to traditional systems. As these innovations continue to evolve, reflow ovens are set to redefine the standards for PCB assembly efficiency in the electronics manufacturing sector.

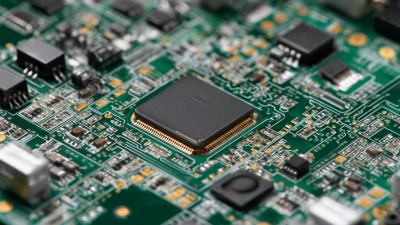

Optimizing PCB design plays a crucial role in enhancing the SMT reflow process, leading to increased efficiency and reliability in PCB assembly. One of the primary considerations in PCB design is the layout, which directly affects the thermal distribution during the reflow soldering process. By strategically placing components with similar thermal requirements closer together, designers can facilitate uniform heat distribution, reducing the chances of overheating or cold solder joints. Additionally, incorporating thermal relief pads can help manage heat effectively, ensuring components maintain their integrity throughout the reflow cycle.

Moreover, the selection of appropriate materials and finishes is essential for optimizing the SMT reflow process. Utilizing lead-free solder and compatible surface finishes can greatly improve solderability and help meet regulatory standards while ensuring reliability. Furthermore, designing PCBs with adequate solder mask openings can ensure proper solder flow during reflow, avoiding issues like insufficient fillet or solder bridging. By focusing on these design optimizations, manufacturers can significantly enhance the overall efficiency of SMT reflow processes, resulting in higher quality assemblies and reduced production costs.

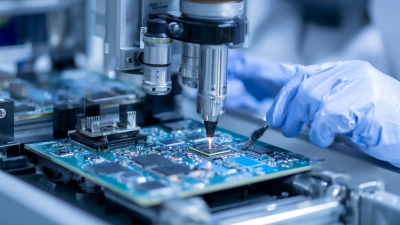

Temperature profiling is a critical aspect of reflow soldering, influencing the integrity and reliability of PCB assemblies. Recent studies have highlighted the interaction of reflow solder flux residue with humidity, revealing its significant impact on the climatic reliability of various component geometries. By utilizing realistic PCBA designs in these investigations, manufacturers can better understand how environmental factors affect solder joints and overall component performance.

Furthermore, advancements in thermal management practices, such as the strategic placement of heat shields during rework processes, have shown promising results in mitigating thermal and mechanical damage to solder joints. These innovations emphasize the importance of precise temperature control and monitoring during the reflow process. As companies explore new technologies, like advanced sensing systems, the feedback loop created through real-time data will undoubtedly enhance temperature profiling strategies, resulting in improved efficiency and reliability in PCB assembly operations.

| Parameter | Value | Best Practices |

|---|---|---|

| Preheat Temperature | 150-180°C | Use a gradual ramp to avoid thermal shock. |

| Soak Time | 60-120 seconds | Ensure uniform temperature distribution. |

| Max Reflow Temperature | 220-260°C | Monitor closely to avoid component damage. |

| Cooling Rate | -4 to -8°C/sec | Quick cooling helps solidify solder joints effectively. |

| Profile Optimization | Customized for PCB design | Test and adjust profiles based on actual results. |

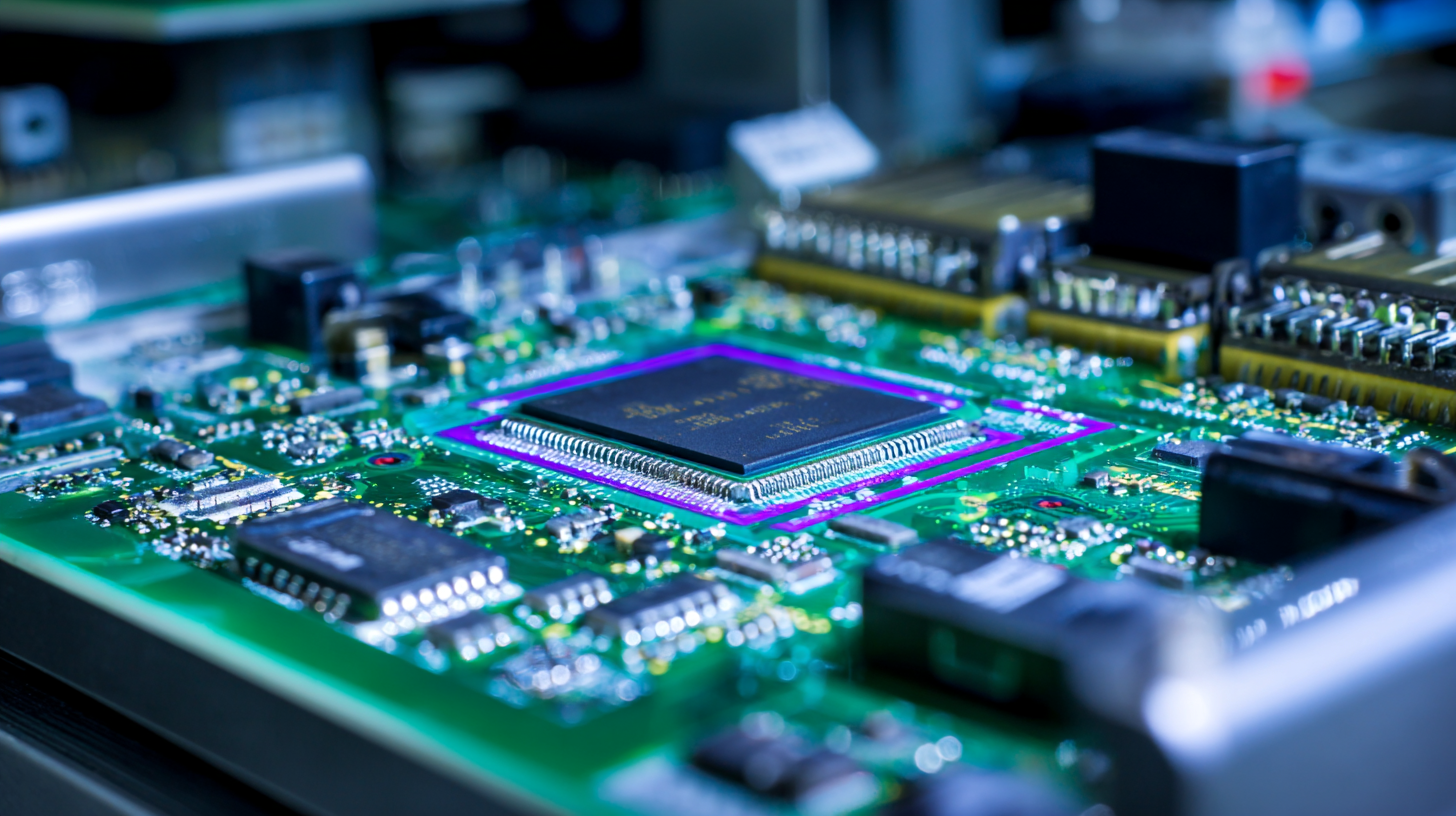

In the evolving landscape of PCB assembly, the integration of SMT reflow technology is critical for enhancing production efficiency. However, manufacturers often face challenges such as insufficient solder joint reliability, thermal profiling issues, and limitations of conventional materials. To overcome these hurdles, adopting innovative materials such as advanced conductive adhesives is essential. These materials ensure optimal signal transmission speeds and stability, addressing the critical demands posed by modern applications like 5G, IoT, and automotive electronics.

Thermal management also plays a vital role in successful SMT reflow processes. Inadequate thermal profiling can lead to improper soldering, leading to high defect rates. To mitigate this risk, utilizing advanced thermal profiling tools and techniques allows manufacturers to achieve consistent results. Moreover, emphasizing electromagnetic compatibility and structural reliability in the design phase can preempt potential issues, ensuring that the final product meets the performance standards demanded by today's high-speed applications. By focusing on these strategies, manufacturers can enhance their output quality while navigating the complexities of SMT reflow technology.