-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In today’s rapidly evolving electronics landscape, maximizing efficiency in PCB assembly is crucial for maintaining a competitive edge. One of the most effective methods employed is SMT Reflow, a process that enhances both the quality and speed of assembly. According to a report by the IPC, over 70% of all electronic components are now assembled using surface mount technology, highlighting the growing reliance on SMT techniques. The SMT Reflow process not only reduces production time but also minimizes solder defects, thereby ensuring higher reliability in electronic devices. Recent studies indicate that implementing advanced SMT Reflow techniques can lead to a reduction in manufacturing costs by as much as 20%, fostering a more streamlined and cost-effective production environment. As demand for complex and compact electronic solutions continues to rise, embracing SMT Reflow techniques becomes essential for manufacturers aiming to optimize their operational workflows and meet market requirements efficiently.

Surface Mount Technology (SMT) reflow techniques are essential for modern PCB assembly, enabling faster production times and higher component density. Reflow soldering, a pivotal process in the SMT assembly line, uses controlled heat to melt solder and create reliable electrical connections. According to the IPC’s report, approximately 75% of all electronic components are assembled using SMT due to its efficiency and effectiveness. This method significantly reduces the footprint of electronic devices, making it pivotal in industries where space is at a premium.

Understanding the basics of SMT reflow involves recognizing the different stages: preheating, soaking, reflow, and cooling. Each stage is critical to ensure the integrity of the solder joint. The IPC 7351 standard emphasizes the precise control of temperatures during reflow to prevent defects such as solder balls or tombstoning, which can lead to failure in electronic circuits. Furthermore, advancements in reflow oven technologies, such as the use of nitrogen atmospheres during soldering, have been shown to enhance the quality of the joints, resulting in a 30% increase in reliability compared to traditional methods. As manufacturers continue to push for higher efficiency and lower defects, mastering SMT reflow techniques becomes increasingly vital.

| Technique | Temperature Range (°C) | Heating Rate (°C/sec) | Cooling Rate (°C/sec) | Application |

|---|---|---|---|---|

| Convection Reflow | 180 - 250 | 1 - 3 | 2 - 5 | Standard Electronics Assembly |

| Infrared Reflow | 150 - 280 | 2 - 4 | 1 - 3 | Small Components |

| Vapor Phase Reflow | 180 - 230 | 0.5 - 1 | 1 - 2 | High-Value Components |

| Laser Reflow | 250 - 350 | 10 - 20 | 3 - 8 | High Precision Applications |

| Hot Air Reflow | 200 - 260 | 3 - 6 | 1 - 2 | Medium Volume Production |

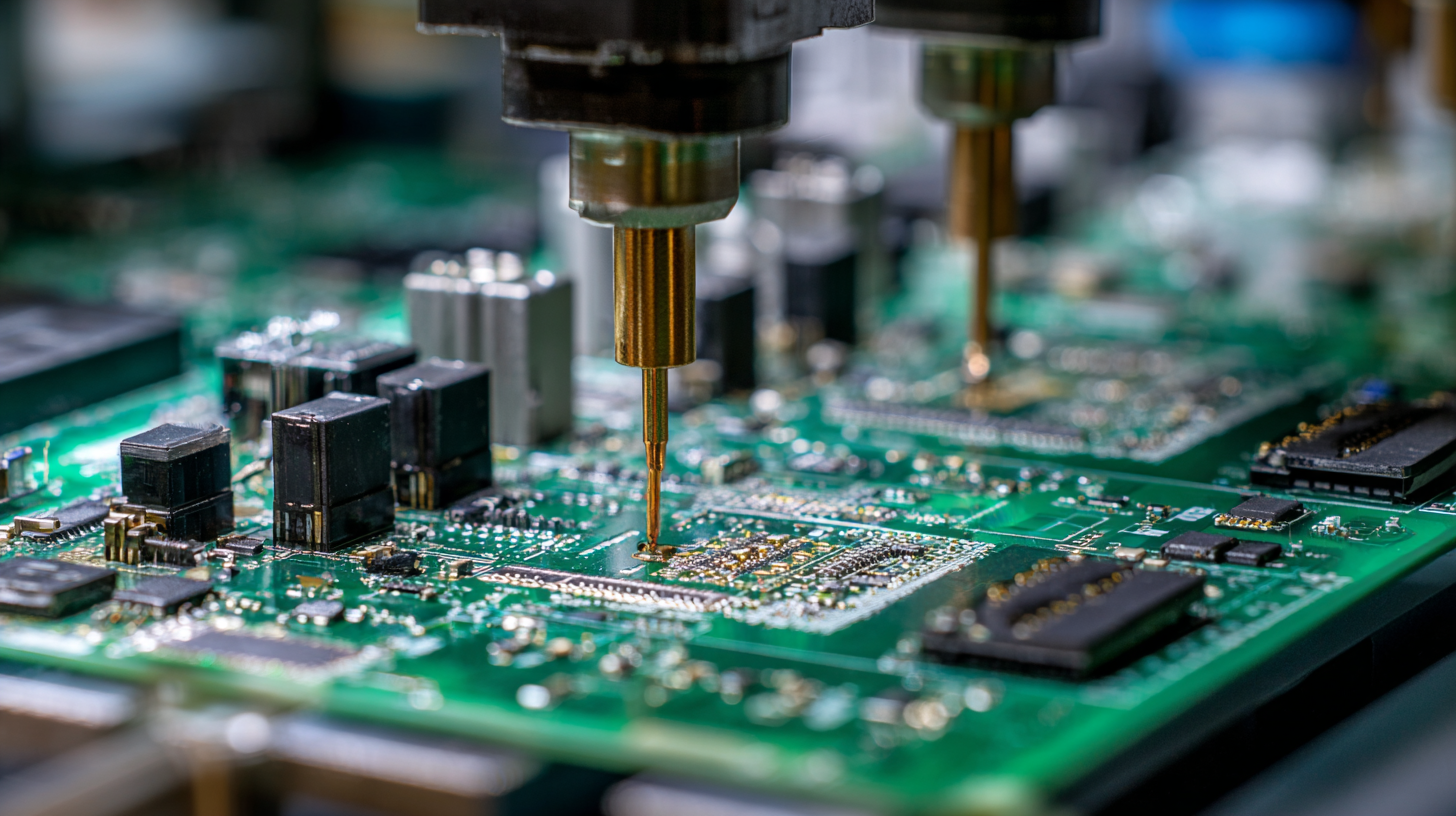

To maximize efficiency in modern PCB assembly, it’s essential to understand the key components and equipment involved in optimizing SMT (Surface Mount Technology) reflow processes. According to a report by IPC, the global market for SMT assembly equipment is projected to reach $4.5 billion by 2025, highlighting the critical role that advanced machinery plays in enhancing production capabilities. Key components like reflow ovens, placement machines, and inspection systems significantly impact the overall performance of SMT processes.

Reflow ovens, in particular, are pivotal in achieving consistent thermal profiles necessary for soldering components to PCBs efficiently. Data from research by the SMTA indicates that an optimized reflow profile can reduce defects by up to 30%, ultimately leading to improved yield rates. Additionally, the integration of high-speed pick-and-place machines can further enhance placement accuracy and throughput, which some industry reports cite can increase production speed by 40% or more. Adopting these technologies not only streamlines operations but also reduces costs associated with rework and product returns, making them essential for any modern PCB assembly line aiming for high efficiency.

Incorporating SMT reflow techniques into PCB assembly can significantly enhance production efficiency. The first step in implementing these methods is to ensure a well-prepared design. This means utilizing design software that supports surface-mounted technology and following best practices for component placement and routing. By optimizing your PCB layout, you can minimize the challenges encountered during the reflow process, ultimately leading to decreased rework and higher yields.

Once the design is finalized, the next step is to select the appropriate solder paste and application method. A stencil printing technique is widely recommended, as it ensures even and precise paste application to the pads. After printing, it’s crucial to establish proper thermal profiles for the reflow oven. This involves carefully setting temperature gradients to avoid thermal shock and achieving effective solder joint formation. Monitoring these parameters during production ensures consistent quality in the final assembly, paving the way for a more efficient manufacturing workflow.

Surface Mount Technology (SMT) reflow soldering is a crucial process in modern PCB assembly, but it comes with its own set of challenges. One prominent issue is the occurrence of solder defects, such as cold solder joints or tombstoning, which can lead to unreliable electrical connections. To overcome these problems, it is essential to optimize the heat profile during the reflow process. Implementing precise temperature controls and ensuring uniform heating can significantly reduce the risk of defects, promoting better solder joint integrity.

Another common challenge in SMT reflow is the inability to achieve proper wetting on various component surfaces, especially with different materials. This can result from insufficient pre-heating or incorrect flux application. Solving this issue requires thorough testing and calibration of both the reflow oven and the materials used. Regular maintenance and monitoring of equipment, along with proper material selection, can enhance wetting and adhesion, leading to more robust assemblies in high-volume production. By addressing these challenges, manufacturers can maximize efficiency and improve the reliability of their PCB assemblies.

In the world of Surface Mount Technology (SMT) for PCB assembly, maintaining high-quality control standards is crucial for achieving optimal efficiency. Implementing robust quality control measures helps in minimizing defects and ensuring reliability in the final products. One best practice involves incorporating real-time monitoring systems throughout the assembly process. These systems allow manufacturers to detect anomalies early, reducing the risk of defects that could escalate costs and time.

**Tip:** Regularly calibrate your SMT machines to maintain precision in solder paste application. Calibration prevents issues such as insufficient solder, which can lead to component failure.

Another key practice is conducting thorough inspections at various stages of the assembly. Utilizing automated optical inspection (AOI) can significantly enhance defect detection capabilities. This technology can spot issues like misaligned components or soldering defects that may go unnoticed in manual inspections.

**Tip:** Implement a regular training program for your assembly line operators to keep them updated on the latest techniques and quality standards. Well-trained personnel are essential for maintaining high-quality outputs.

By fostering a culture of quality and implementing strategic inspection methodologies, manufacturers can significantly improve their SMT PCB assembly processes, leading to better overall efficiency and product reliability.

This bar chart illustrates the average defect rates in PCB assemblies using various SMT reflow techniques. Lower defect rates indicate higher efficiency and better quality control.