-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In the world of manufacturing, the Radial Insertion Machine plays a crucial role. Experts like Dr. Emily Carter, a leading engineer in automated systems, emphasize its significance: "The Radial Insertion Machine revolutionizes our approach to efficiency." This machine is designed to insert various components radially into a workpiece, improving precision and speed.

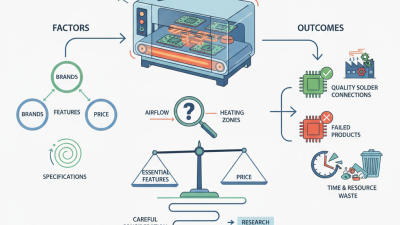

Manufacturers rely on this technology for assembling intricate devices. The machine can adjust to different sizes and shapes, making it versatile. While it provides many benefits, such as increased productivity, it is not without challenges. Proper calibration and maintenance are essential to avoid errors.

Understanding how a Radial Insertion Machine functions can enhance production lines. Whether adjusting the speed or configuring insertion angles, operators must stay sharp. The pursuit of perfection in manufacturing processes requires constant reflection on technology's role and limitations.

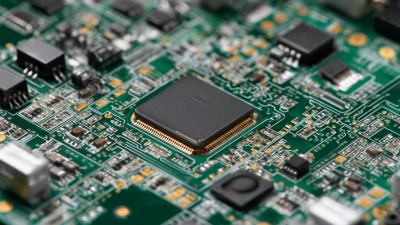

A Radial Insertion Machine is a specialized device used in manufacturing. It efficiently inserts components like pins and sockets into printed circuit boards (PCBs). The machine's design allows for high-speed operations. Its unique radial arrangement provides precise component alignment, reducing the risk of errors. According to industry reports, these machines can boost production rates by up to 50%. This efficiency is crucial as demand for electronic devices continues to rise.

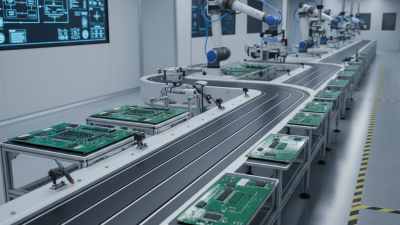

In use, the machine automates the insertion process. A feeder supplies components, and the machine delivers them to the designated locations. This reduces labor costs and minimizes human error. However, reliance on automation can be a double-edged sword. If not maintained properly, machines can lead to significant downtimes. Reports indicate that unplanned maintenance can increase production costs by 30%.

Understanding the limitations of a Radial Insertion Machine is vital for manufacturers. They must recognize that while machines enhance efficiency, they also require oversight. Balancing automation with skilled labor can create a more resilient production line. Investing in both technology and training is essential to navigating potential pitfalls.

Radial insertion machines play a crucial role in manufacturing. They are designed to place components into printed circuit boards (PCBs) with precision. The key components make this possible. A feeder holds the components securely, ensuring a steady supply during operation.

Next, a robotic arm maneuvers the components from the feeder. It must be agile and accurate. Some machines use pneumatic or electric actuation for movement. The arm positions the component correctly over the PCB. If the alignment is off, it can lead to defects. Calibration is essential to avoid such issues.

The machine also includes a vision system for quality control. Cameras monitor the placement of every component. This system helps identify errors in real time. Operators must regularly check the camera’s alignment. Miscalibration can result in oversights. Moreover, the software controlling the machine needs periodic updates for optimal performance. A neglected system can hinder productivity. Manufacturing relies on such machines, but attention to detail remains vital for success.

| Component | Description | Function |

|---|---|---|

| Feed System | Automates the delivery of components to the insertion point. | Ensures constant supply and placement of parts for efficient operation. |

| Insertion Head | The mechanism that securely inserts components into their designated location. | Handles precise placement and ensures that parts are inserted correctly. |

| Control System | Programmable system that manages operation and timing of the machine. | Allows flexibility and precision in machine operation. |

| Sensing Mechanism | Sensors for detecting component presence and correct positioning. | Enhances accuracy and quality control during the insertion process. |

| Chassis | The physical structure that houses and supports the machine's components. | Provides stability and durability for machine operation. |

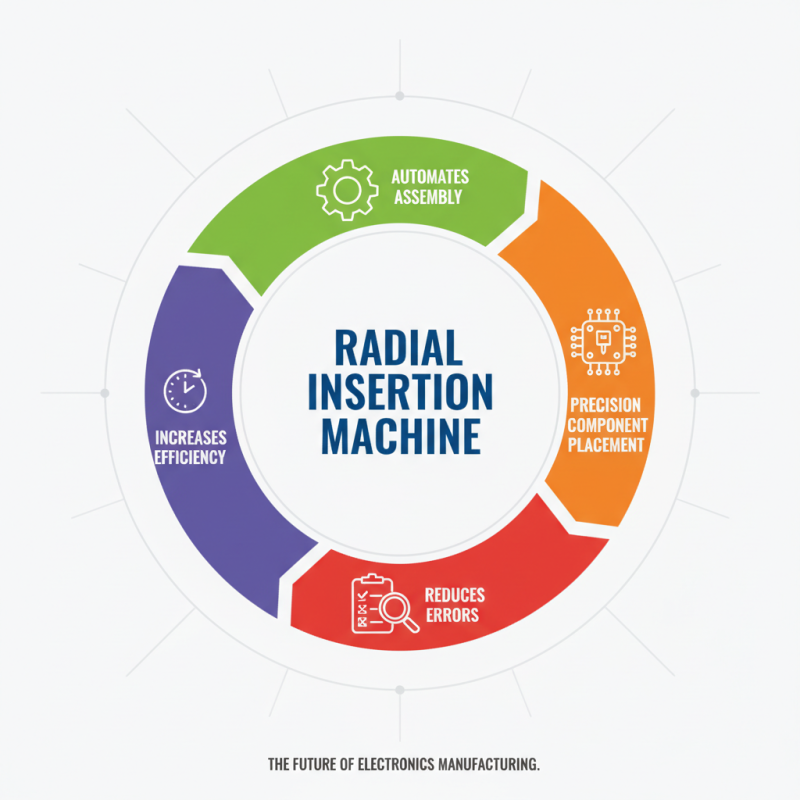

A Radial Insertion Machine is a vital tool in modern manufacturing. It automates the assembly of components, enhancing efficiency. This machine excels in inserting radial parts precisely into various substrates. Many industries rely on it, especially in electronics and automotive sectors.

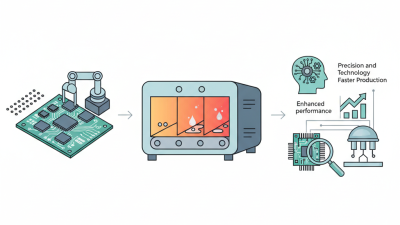

The operation of a Radial Insertion Machine involves several key steps. A pick-and-place mechanism first selects the component. This happens swiftly, mitigating timing issues. Once the component is in position, the machine inserts it accurately into the specified holes. According to industry reports, these machines can achieve insertion rates of up to 6000 components per hour. Precision is crucial here, as any misalignment can lead to defects, affecting product quality.

Operators must monitor the machine regularly. Calibration is essential to maintain accuracy. Failure to do so may result in increased scrap rates. Furthermore, training for technicians is necessary. Without proper knowledge, the potential of the machine remains untapped. This reliance on human oversight can lead to inconsistencies in performance. A balanced approach is needed to ensure the machine operates at its best while reducing risks.

Radial insertion machines play a crucial role in various industries. They are designed to insert components into circuit boards and other assemblies efficiently. This technology is widely used in electronics manufacturing, automotive production, and appliance assembly.

In electronics, radial insertion machines streamline the process of placing components like resistors and capacitors. These machines can significantly reduce production time and increase accuracy. They help achieve a higher yield rate by minimizing errors. However, training operators to use these machines effectively remains a challenge for many manufacturers.

In the automotive sector, radial insertion machines assist in the assembly of complex electronic systems. This includes crucial components like sensors and control units. The precision of these machines supports the high standards required in automotive manufacturing. Yet, companies often struggle with machine maintenance and the calibration of components. Balancing efficiency with quality control is an ongoing concern in this field.

A Radial Insertion Machine is designed to automate the assembly process. This machine excels in inserting components into circuit boards or panels. It operates with precision, reducing the margin for error. In a world where efficiency matters, the advantages of this technology stand out.

One major benefit is speed. The machine can perform multiple insertions in a matter of seconds. This is crucial for increasing production rates. Operators can focus on other tasks rather than manual insertion. Additionally, it minimizes the risk of human error, which can lead to defects. However, careful training is needed to ensure the machine is used effectively.

Cost savings are also important. While there is an upfront investment, the long-term benefits often outweigh the costs. Reduced labor expenses and fewer errors contribute to a healthier bottom line. Yet, companies must remain vigilant. An improperly calibrated machine can cause issues in production. Continuous monitoring and maintenance are essential for optimal performance.