-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

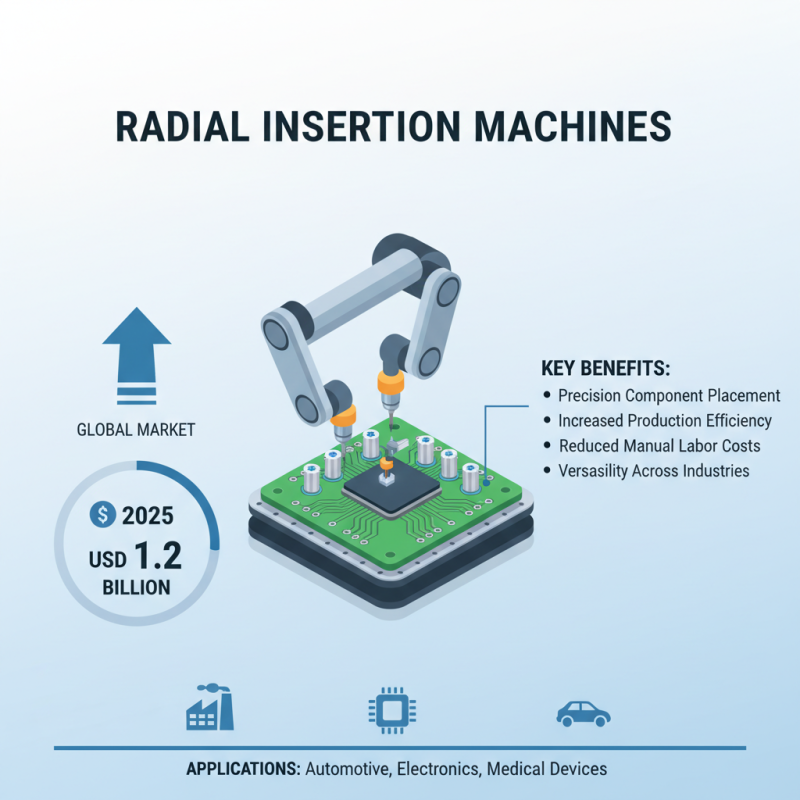

In today's manufacturing landscape, the importance of automation cannot be overstated. Radial Insertion Machines play a crucial role in streamlining production processes across various industries. According to a report by MarketsandMarkets, the global market for Radial Insertion Machines is expected to reach $1.2 billion by 2025, showcasing rapid growth driven by increasing demand for precision assembly.

Industry expert Dr. James Carson emphasizes the significance of these machines, stating, "Radial Insertion Machines deliver unmatched efficiency in component placement." His insights reflect a growing consensus in the field. Many manufacturers report a reduction in labor costs and improved product quality due to automation.

Despite their advantages, some challenges remain. Implementing this technology requires a careful assessment of existing processes. Companies must ensure proper training and integration into their workflow. The benefits of Radial Insertion Machines are clear, yet they also require thoughtful consideration to maximize their impact.

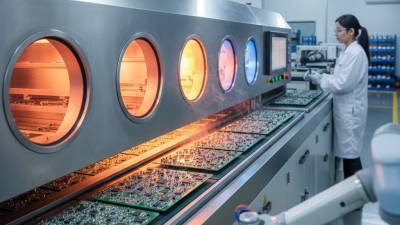

Radial insertion machines are crucial in various industries. They excel in placing and securing components onto printed circuit boards (PCBs). According to industry research, the global market for these machines is projected to reach $1.2 billion by 2025. This rise highlights their growing importance in manufacturing.

These machines streamline the assembly process. They offer high accuracy and speed, which significantly reduces production time. A study from TechNavio indicates that companies using radial insertion technology can improve efficiency by up to 30%. However, not every machine maintains consistent performance. Regular maintenance is essential to avoid breakdowns.

In sectors like automotive and consumer electronics, the applications are diverse. For instance, they are used in producing connectors, resistors, and capacitors. The machine's design allows for flexible operations. Yet, some operators face challenges calibrating the machines correctly, leading to errors. Continuous training can help alleviate these issues. The evolving technology demands constant adaptation.

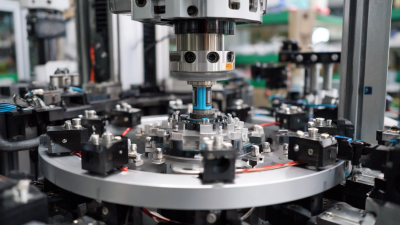

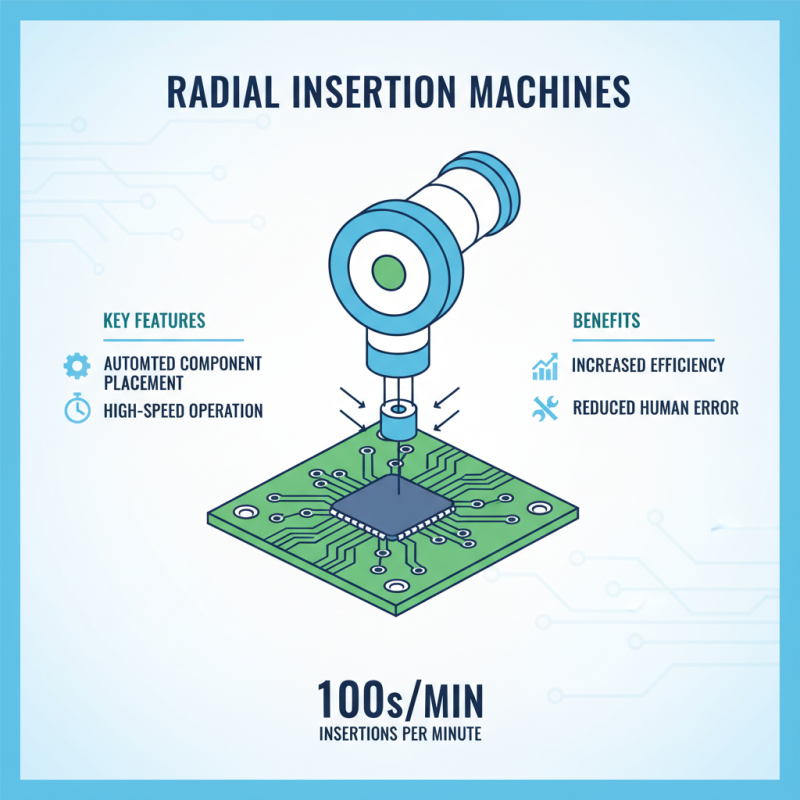

Radial insertion machines are essential in modern manufacturing. They automate the process of inserting components into printed circuit boards (PCBs). This increases efficiency and reduces human error. One key feature is their high-speed operation. Many machines can perform hundreds of insertions per minute. This speed is crucial for large production runs.

Another important feature is precision alignment. These machines often integrate advanced sensors and vision systems. This ensures that each component is placed perfectly on the PCB. Errors can be costly and time-consuming. Yet, despite these advancements, some operators may struggle with machine setup. Training is essential to utilize these features fully.

Flexibility is also a significant benefit. Many radial insertion machines can handle various component sizes and types. However, this adaptability can be overwhelming. Different materials and shapes may require adjustments that aren’t straightforward. Operators may need to experiment to achieve the best results. The learning curve can be steep, but the potential rewards are substantial.

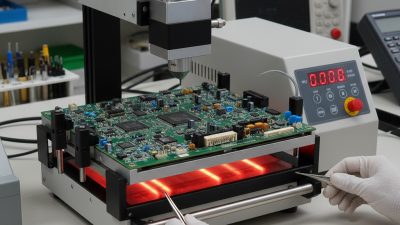

Radial insertion machines are becoming essential in modern manufacturing. They provide various benefits that enhance efficiency and productivity. These machines allow for precise placement of components, ensuring fewer errors. This is particularly useful in high-volume production where accuracy is critical.

The automation capabilities of radial insertion machines minimize manual labor. Workers can focus on more complex tasks while machines handle repetitive assembly processes. However, there's a learning curve when integrating these machines into existing workflows. Staff training is necessary, which can initially slow down production. Yet, the long-term benefits often outweigh these challenges.

Additionally, these machines can handle a variety of components. This flexibility can lead to an increase in production diversity. However, adapting to different component types may require adjustments and recalibration. Companies should consider these aspects while investing in such equipment.

Balancing technology and human skills is vital for optimal outcomes.

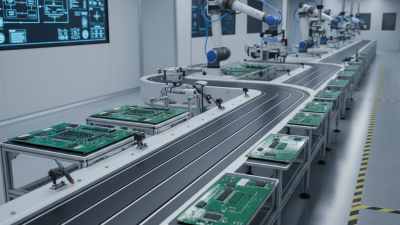

When comparing radial insertion machines to other types, several factors come into play. Radial machines often excel in speed and efficiency. According to industry reports, these machines can increase production rates by up to 25%. Their design allows components to be placed accurately and quickly. This feature reduces cycle times significantly.

In contrast, other insertion machines may struggle with the same efficiency. For instance, axial insertion machines often take longer to complete similar tasks. They require more space and may not be as versatile. Radial machines have a distinct advantage in tight manufacturing environments. This versatility makes them a preferred choice in various applications, from electronics to automotive components.

Tip: Consider the specific needs of your production line. Analyze whether speed or precision is more critical for your operations. Sometimes, it pays to invest in a radial machine for higher output. However, reflect on the financial implications. A higher initial investment might not always lead to a faster return on investment. Be sure to weigh all factors before deciding.

As radial insertion technology advances, we see exciting trends shaping the future. One emerging trend is the integration of automated systems. These systems aim to improve efficiency and precision while reducing human error. Robotics and AI play a role in streamlining operations. However, relying too heavily on automation may lead to unexpected issues. Proper training for operators remains essential.

Another trend is the shift towards more sustainable materials. Manufacturers are exploring eco-friendly options, reducing waste in packaging and production. This shift not only benefits the environment but also meets consumer demand for greener products. Yet, the transition is not without challenges. Companies must balance performance and sustainability.

Tips for adapting to these trends include investing in staff training. Educate your team on new technologies to avoid potential pitfalls. Maintaining flexibility in your production process is vital, too. Embrace change while being cautious of overdependence on technology. Keeping your operations efficient and sustainable requires continuous assessment and improvement.

| Feature | Description | Benefits | Future Trends |

|---|---|---|---|

| High Speed Operation | Capable of inserting components rapidly. | Increased productivity and reduced cycle times. | Integration with AI to optimize speed further. |

| Precision Mechanics | Uses advanced mechanics for accurate insertion. | Minimized errors and improved product quality. | Development of self-calibrating systems. |

| User-Friendly Interface | Intuitive controls for easy operation. | Reduced training time and operator errors. | Adoption of touchless controls and VR interfaces. |

| Modular Design | Easily customizable for different applications. | Flexibility in production setups. | Emergence of universal modules for multi-use machines. |

| Data Connectivity | Integration with IoT for real-time monitoring. | Enhanced decision-making based on analytics. | Advancements in predictive maintenance capabilities. |