-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

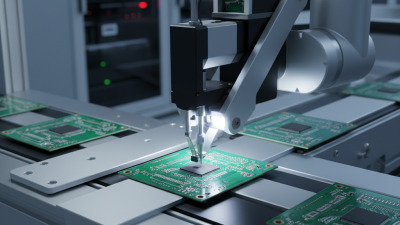

Choosing the right SMD Reflow Oven can transform your PCB production process. These ovens are essential for soldering surface mount devices effectively. The precision of an SMD Reflow Oven can dramatically impact the quality of your final products.

Many manufacturers face challenges when selecting the best oven. Factors such as size, temperature accuracy, and user-friendliness are crucial. A well-chosen oven can reduce defects and improve efficiency. However, not all options meet industry standards.

Some production teams overlook maintenance. Regular checks ensure consistent performance. Investing in the best SMD Reflow Oven may seem costly, yet the long-term benefits are significant. As the technology evolves, the need for an upgraded oven becomes evident. Reflect on your current equipment's limitations and how a new oven could bridge those gaps.

SMD reflow ovens play a crucial role in PCB production. These devices ensure that surface mount devices are heated uniformly, allowing for optimal soldering. According to industry reports, over 70% of manufacturers cited reflow accuracy as a primary concern. Proper temperature profiles are essential for reliable connections, affecting the overall quality of the PCBs.

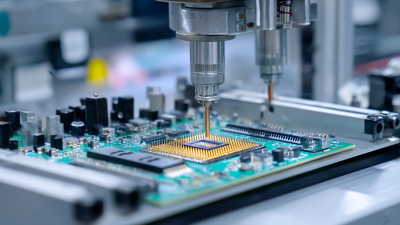

When selecting an SMD reflow oven, consider these tips. Look for ovens with adjustable temperature settings. Flexibility allows for better adaptation to various components. Evaluate the heating zones; multiple zones provide more precision in temperature control. Data shows that machines with zone control can improve soldering consistency by up to 30%.

Not all production facilities utilize reflow ovens effectively. Some may overlook routine maintenance. Inadequate care can lead to inconsistent heating. This inconsistency may result in defects, increasing production costs. Assess the oven’s reliability regularly to prevent disruptions in the production line. Documentation of the heating process can also help identify recurring issues.

When selecting the best SMD reflow oven for PCB production, certain features are crucial. Temperature accuracy is vital. An oven that maintains precise temperatures ensures consistent soldering results. Look for a model with multiple heating zones. This allows for better control, especially for complex PCBs. You want to avoid cold spots or overheating, which can lead to defective boards.

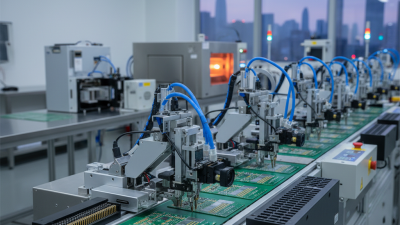

Consider the oven's size and capacity as well. A compact oven may save space but limit production volume. Evaluate your production needs. Large batches may require a bigger unit. Additionally, pay attention to the conveyor speed. A slow speed can become a bottleneck. But if it’s too fast, the solder may not melt correctly.

Another aspect to reflect on is energy efficiency. An oven that consumes less energy can save costs in the long run. However, achieving this should not compromise performance. Finding the right balance can be challenging. Finally, think about the ease of maintenance. An oven that requires frequent repairs can disrupt production. Look for accessible support and parts availability. Your choice will significantly impact production quality and efficiency.

| Feature | Importance | Typical Value | Notes |

|---|---|---|---|

| Temperature Zones | Allows for control over heating profiles | Up to 10 | Multiple zones improve soldering quality |

| Conveyor Speed | Affects throughput of production line | 200-1000 mm/min | Optimizing speed improves efficiency |

| Cooling System | Rapid cooling to minimize defects | Air or Fan-based | Essential for quality control |

| Energy Efficiency | Reduces operational costs | < 6 kW | Lower energy consumption is preferable |

| Control Interface | User-friendly operation | Touchscreen / Software | Simplifies programming and monitoring |

| Size and Footprint | Fits into production space | Varies by model | Consider available floor space |

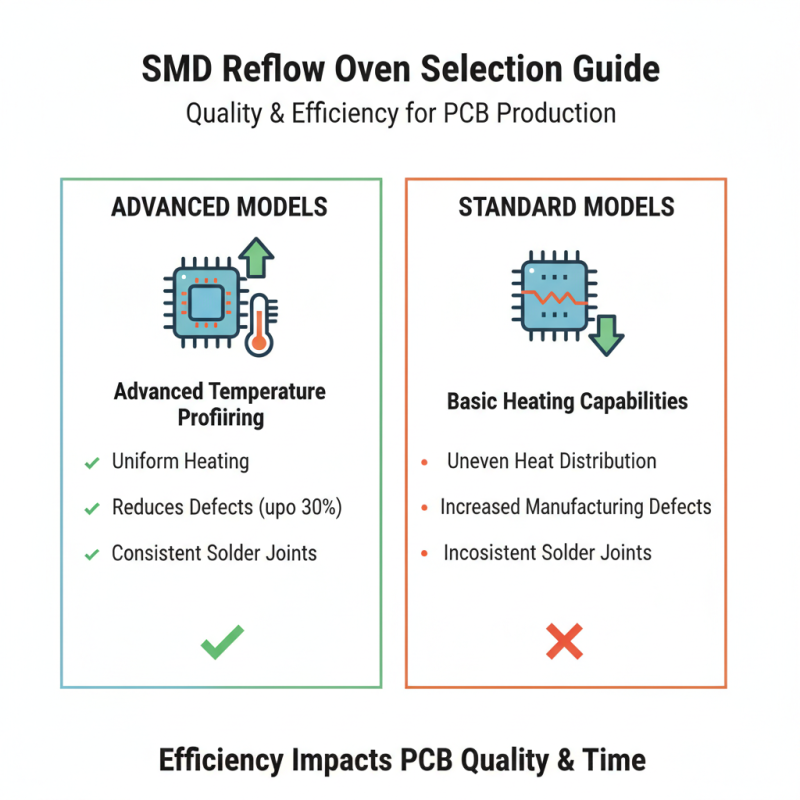

When selecting an SMD reflow oven, understanding the differences among various models is crucial. A recent industry report indicated that the efficiency of the reflow oven can significantly impact PCB production quality and time. For instance, ovens with advanced temperature profiling capabilities can reduce manufacturing defects by up to 30%. In contrast, less sophisticated models may struggle with uniform heating, leading to inconsistent solder joints.

Tips: Consider ovens with multiple heating zones. This feature allows for better control, ensuring even heat distribution. A well-designed temperature curve can enhance solder joint reliability.

Another aspect to consider is the oven's footprint. Compact models may appeal due to limited space but usually come with trade-offs. They might have reduced capacity or fewer features. According to industry surveys, about 40% of manufacturers find themselves upgrading or replacing their initial choices due to space limitations.

Tips: Analyze your production volume before making a decision. Look for a balance between size and output capabilities to avoid future adjustments.

Ultimately, choosing the right SMD reflow oven involves careful consideration of model specifications and real-world performance. Exploring user reviews and technical evaluations can provide insights into the ovens' compatibility with your production needs.

Investing in high-quality SMD reflow ovens can significantly enhance PCB production efficiency. These ovens ensure precise temperature control, crucial for soldering components effectively.

Accurate heating prevents cold solder joints and improves overall board reliability. When components fail due to poor soldering, costs increase due to rework. A reliable oven helps minimize these issues, making it a cost-effective choice.

While lower-priced ovens may seem tempting, they often compromise on performance. Frequent breakdowns can lead to production delays. The financial impact of these delays often outweighs initial savings. High-quality ovens come with better warranties and support, which can save money over time.

Furthermore, they consume less energy, providing additional savings in utility bills.

Choosing a high-quality oven requires careful assessment. Not every feature may be necessary for your specific production needs.

An oven with excessive capabilities can lead to underutilization, wasting resources. It's vital to balance cost with the right specifications for your PCB production goals.

This thoughtful selection process can lead to enduring savings and improved quality in the long run.

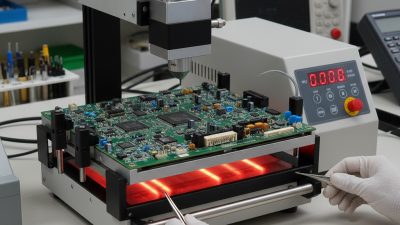

A reflow oven is essential for PCB production. To ensure its longevity, regular maintenance is crucial.

One effective tip is to perform daily cleanings. Dust and flux buildup can affect performance. Use a soft cloth and appropriate cleaning solutions to wipe down the exterior and interior. Regularly check and clean the filters, too. Clogged filters can lead to overheating.

Next, calibrate the oven periodically. Temperature consistency is key in soldering. Improper calibration can lead to defects in the PCB. Consider keeping a log of calibration dates and results. This practice helps track any changes in performance.

Finally, monitor the oven's usage. Overuse can lead to wear and tear. Schedule routine inspections to identify potential issues early. Taking these steps can prolong your reflow oven's life and improve production quality. Regular maintenance may take time but will pay off in the end.