-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In the rapidly evolving landscape of electronics manufacturing, the role of advanced Solder Paste Printers has become increasinglycritical for achieving higher efficiency and quality in printed circuit board (PCB) production. According to a recent report from the IPC (Institute for Printed Circuits), the global demand for PCBs is projected to reach $78 billion by 2025, with precise solder paste application being a key factor in maintaining production standards.

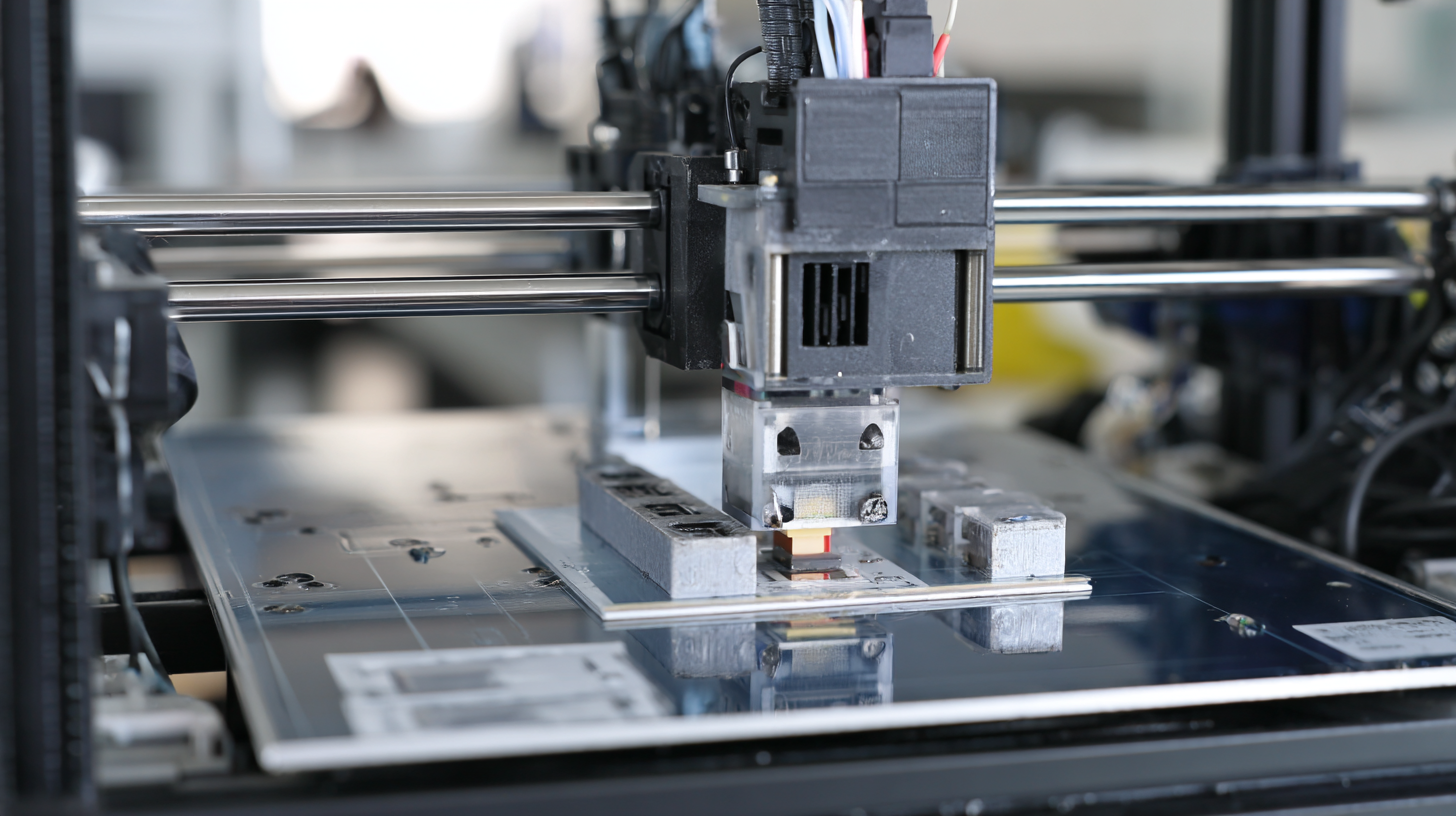

The advent of innovative Solder Paste Printers has significantly reduced defects while enhancing manufacturing speed, addressing the challenges posed by fine-pitch components and high-density designs. As manufacturers strive for greater automation and quality control, integrating cutting-edge Solder Paste Printer technology not only streamlines the production process but also contributes to the overall sustainability of electronics manufacturing, aligning with the industry's long-term goals for efficiency and reliability.

In the rapidly evolving landscape of PCB production, the integration of

advanced automation technologies

in solder paste printing is transforming manufacturing efficiency and quality.

According to a report by IPC, automated printing systems can enhance printing

accuracy by up to 30%,

significantly reducing defects associated with manual processes. This level of

precision is crucial as PCB designs become increasingly complex, requiring

tighter tolerances and higher component densities.

Moreover, automation in solder paste printing minimizes the risk of human error,

further streamlining production lines. Notably, a study by SEMI indicates that

fully automated systems can increase production speeds by 50%,

allowing manufacturers to meet tight deadlines without compromising quality. The

use of automated printers also facilitates consistent paste deposition, leading to

improved solder joint reliability—a critical factor in ensuring the longevity

and performance of electronic devices.

Tips:

Consider investing in solder paste printers that offer programmable features

for various PCB formats, as this versatility can significantly enhance your

production capabilities. Regular maintenance and software updates for these

automated systems can also help sustain peak performance and extend the

lifespan of your equipment.

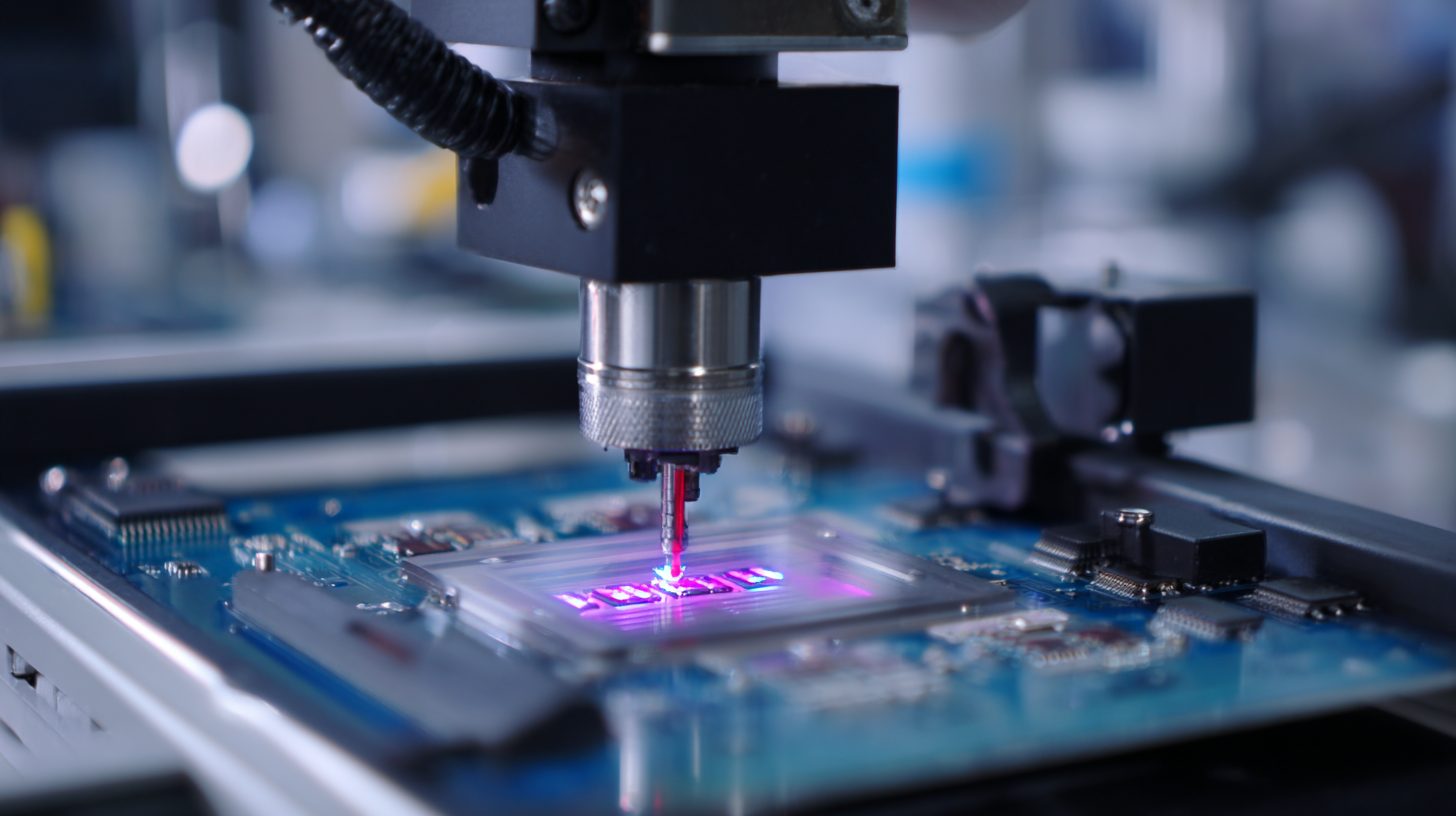

The introduction of advanced solder paste printers has significantly transformed the PCB manufacturing landscape. These machines are designed with state-of-the-art technologies that enhance precision during the printing process. One key feature is the use of high-resolution cameras for real-time inspection, which ensures that every solder paste deposit is accurate and consistent. This capability drastically minimizes defects, which is crucial for maintaining the quality of complex electronic boards.

Another standout feature of advanced solder paste printers is their ability to adapt to various paste types and viscosity levels. This adaptability allows for better process optimization, reducing downtime during production changes. Additionally, many modern printers incorporate automatic cleaning systems, which not only streamline operations but also extend the life of the printing equipment.

**Tip:** Regularly calibrate your solder paste printers to maintain optimal performance. Even minor misalignments can lead to significant defects in your PCB boards.

**Tip:** Experiment with different solder paste materials to determine which combinations yield the best performance for your specific manufacturing needs. By fine-tuning your materials, you can enhance the reliability of your PCB assemblies.

| Feature | Description | Benefits |

|---|---|---|

| High Precision Printing | Utilizes advanced software algorithms for precise alignment and printing. | Minimizes misprints and enhances the quality of PCB assemblies. |

| Automated Paste Inspection | Incorporates machine vision systems to inspect solder paste application. | Reduces defects and improves reliability of solder joints. |

| User-Friendly Interface | Features an intuitive control panel and touchscreen interface. | Enhances operator efficiency and reduces training time. |

| Flexible Printing Capabilities | Able to print various paste types and adjust to different board sizes. | Increases versatility for varied production needs. |

| Advanced Temperature Management | Features controlled heating elements to maintain optimal paste viscosity. | Ensures consistent paste performance and reduces waste. |

The quality of solder paste plays a crucial role in PCB manufacturing efficiency. According to a recent report from IPC, approximately 30% of PCB defects are attributed to inadequate solder paste application, which highlights the importance of precision in the printing process. Advanced solder paste printers are designed to improve both the consistency and accuracy of solder paste deposits, leading to fewer defects and reduced rework rates. This improvement not only speeds up the manufacturing process but also enhances overall product reliability, which is vital in demanding sectors such as automotive and aerospace.

The quality of solder paste plays a crucial role in PCB manufacturing efficiency. According to a recent report from IPC, approximately 30% of PCB defects are attributed to inadequate solder paste application, which highlights the importance of precision in the printing process. Advanced solder paste printers are designed to improve both the consistency and accuracy of solder paste deposits, leading to fewer defects and reduced rework rates. This improvement not only speeds up the manufacturing process but also enhances overall product reliability, which is vital in demanding sectors such as automotive and aerospace.

Furthermore, a study conducted by SMT Magazine revealed that implementing high-quality solder paste printers can increase throughput by as much as 25%. This efficiency gain is achieved by minimizing waste and ensuring optimal transfer efficiency, which is particularly significant given that poor solder paste quality can lead to increased defects and downtimes. With the continuous advancement in solder paste technology and printing methods, manufacturers are better equipped to meet the growing demands for high-performance PCBs while maintaining cost-effectiveness in their production processes.

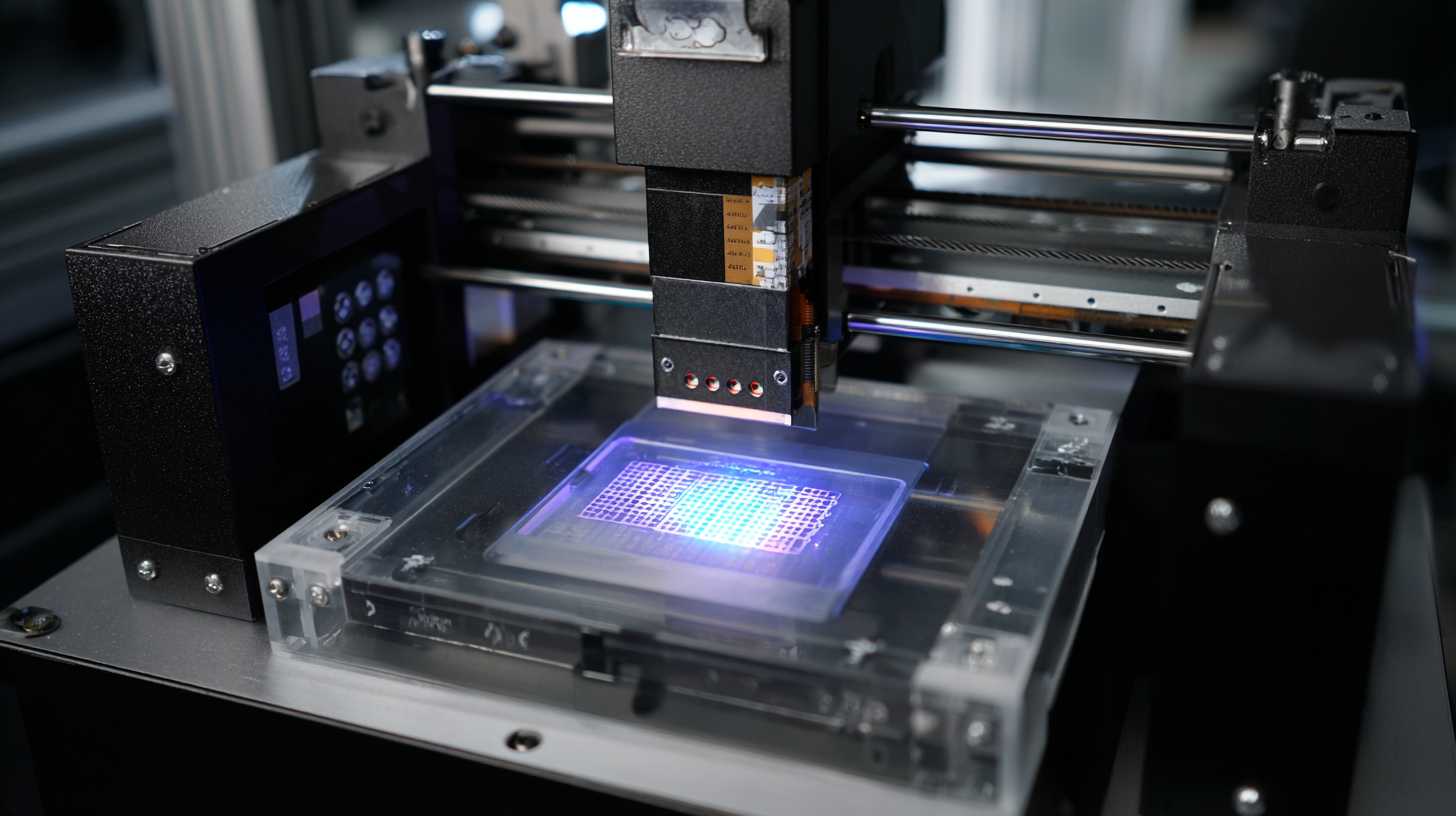

The landscape of PCB manufacturing is undergoing a significant transformation, driven largely by advancements in solder paste technologies. As the demand for higher precision and efficiency increases, new trends such as automation, nano-coating, and advanced viscosity control systems are emerging. These innovations not only enhance the accuracy of solder paste application but also reduce waste and improve overall productivity. Automated solder paste printers are becoming the industry standard, enabling manufacturers to achieve finer pitch placements and tighter tolerances that were previously unattainable.

Another noteworthy trend is the integration of smart technologies into solder paste printing processes. The use of artificial intelligence and machine learning algorithms allows for real-time monitoring and adjustments, ensuring optimal performance throughout the production run. This capability significantly minimizes human error and enhances yield rates. Furthermore, the development of eco-friendly solder pastes that meet regulatory standards while maintaining performance metrics is paving the way for sustainable manufacturing practices in the electronics sector. Embracing these advanced solder paste technologies is essential for manufacturers looking to stay competitive in an ever-evolving market.

In the rapidly evolving landscape of PCB manufacturing, the adoption of advanced solder paste printers has proven to be a game-changer. According to a recent report by IPC, manufacturers utilizing modern solder paste printing solutions have seen a 20% increase in production efficiency while simultaneously reducing material waste by up to 15%. This significant improvement can be attributed to enhanced precision in solder paste application, leading to better overall product quality and reliability.

Case studies from leading firms such as Asteelflash and Jabil highlight the transformative impact of these technologies. Asteelflash reported a noteworthy 30% decrease in defect rates after implementing state-of-the-art solder paste printers, allowing them to meet stringent customer demands in the automotive sector. Meanwhile, Jabil showcased a remarkable reduction in cycle time, enabling quicker turnaround on prototype boards, which is crucial in today's fast-paced electronics market. These real-world applications illustrate not only the technical benefits but also the competitive advantages gained from investing in modern solder paste printing solutions.