-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

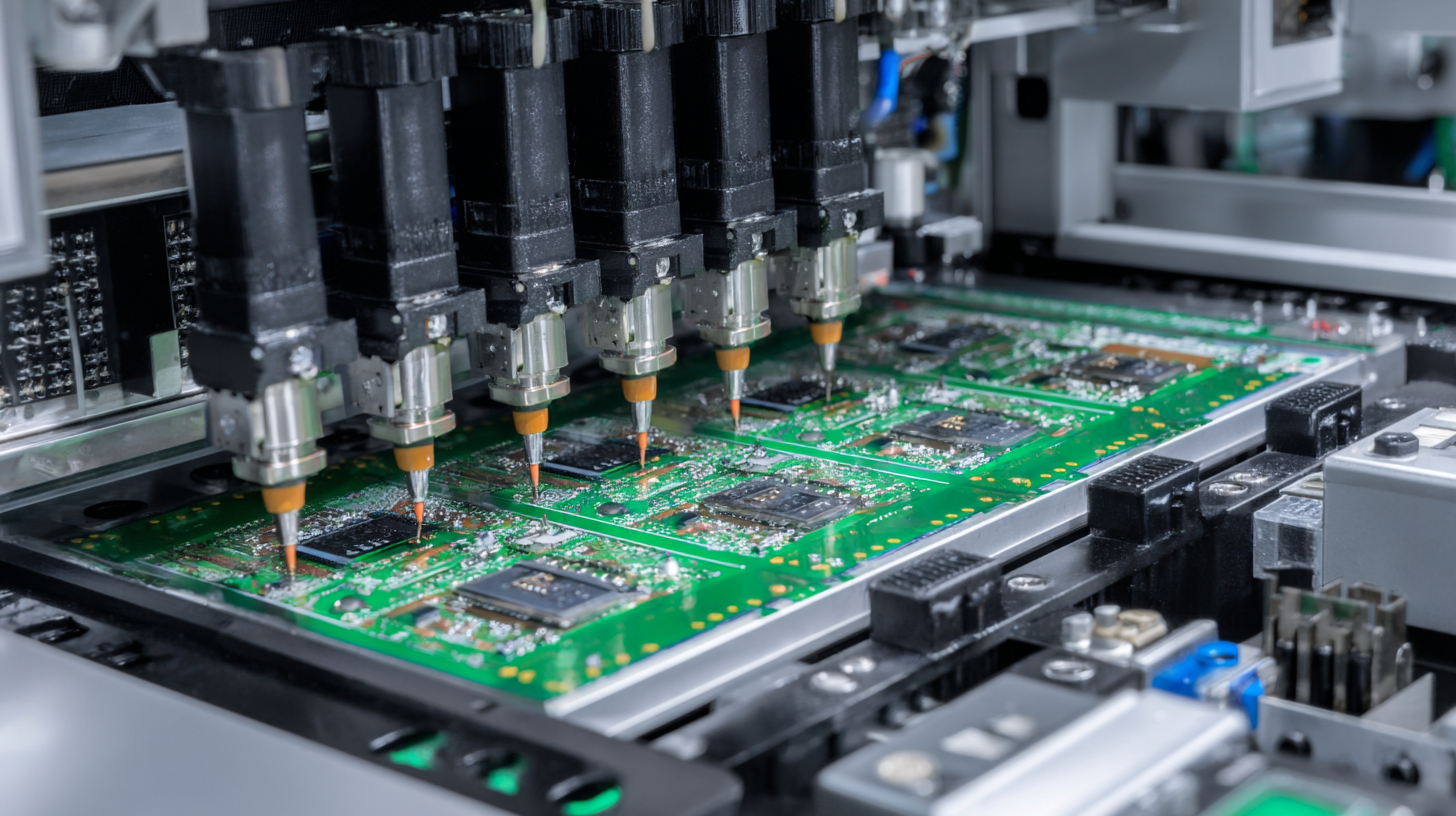

In the rapidly evolving landscape of electronics manufacturing, the importance of precision in PCB assembly cannot be overstated. One of the critical components of this process is the application of solder paste, which serves as the foundational element for mounting electronic components onto circuit boards. To ensure the integrity and reliability of solder paste application, Solder Paste Inspection Machines have emerged as indispensable tools. These machines play a vital role in identifying defects such as misalignment, insufficient paste volume, or contamination, thereby significantly reducing the likelihood of failures in the final product. As manufacturers strive for higher efficiency and quality in their assembly lines, the integration of Solder Paste Inspection Machines not only enhances operational effectiveness but also contributes to the overall advancement of manufacturing technologies. Embracing this innovation is crucial for companies aiming to stay competitive in the high-stakes field of electronics production.

Solder paste inspection (SPI) machines play a vital role in ensuring the quality and reliability of printed circuit boards (PCBs). These machines are designed to assess the application of solder paste on a PCB prior to component placement, a critical step in the assembly process. According to a market research report by Technavio, the global solder paste inspection market is expected to grow at a CAGR of over 10% through 2025, underscoring the increasing importance of these machines in high-precision manufacturing environments.

SPI machines utilize advanced imaging technology to detect inconsistencies in solder paste application, such as insufficient amount, misalignment, and even paste contamination. Key features of modern SPI systems include 3D inspection capabilities and the usage of algorithms for enhanced defect detection. A study by IPC indicates that the implementation of SPI can reduce rework costs by up to 40%, emphasizing the economic advantages of integrating this technology into manufacturing processes. As electronic devices continue to miniaturize and become more complex, the demand for solder paste inspection machines will likely increase, establishing them as essential tools in the realm of PCB assembly.

| Parameter | Description | Importance in PCB Assembly |

|---|---|---|

| Machine Type | Automated Solder Paste Inspection | Enhances accuracy in solder paste application. |

| Inspection Method | SPI (Solder Paste Inspection) | Ensures solder paste thickness meets specifications. |

| Software Features | Real-time analysis and reporting | Facilitates immediate corrective actions. |

| Detection Accuracy | Up to 99.9% | Reduces defects in PCB assemblies. |

| Cycle Time | 1-3 seconds per board | Improves production efficiency. |

| Integration Capability | Compatible with SMT lines | Streamlines overall production workflow. |

| User Interface | Intuitive touchscreen operation | Reduces training time for operators. |

Solder paste inspection (SPI) machines play a crucial role in ensuring the reliability and efficiency of PCB assembly processes. By accurately measuring the amount of solder paste printed on the PCB, these machines help reduce defects such as solder bridging and insufficient solder, which can result in costly rework and downtime. According to a report from IPC, implementing automated inspection systems can decrease defect rates by as much as 50%, thus enhancing overall production quality.

One of the key benefits of solder paste inspection is the ability to provide real-time feedback during the manufacturing process. This immediate data allows manufacturers to identify and correct printing issues before the assembly stage, leading to significant cost savings. Furthermore, a study by VDC Research indicates that companies utilizing SPI technology can achieve an increase in production yield by up to 30%, thereby streamlining operations.

Tips: Regularly calibrate your SPI machines to maintain accuracy and ensure comprehensive coverage during inspection. Additionally, integrating SPI data with your overall quality management system can facilitate better decision-making and continuous improvement in the manufacturing process. By leveraging the power of solder paste inspection, manufacturers can not only enhance product quality but also drive operational efficiency.

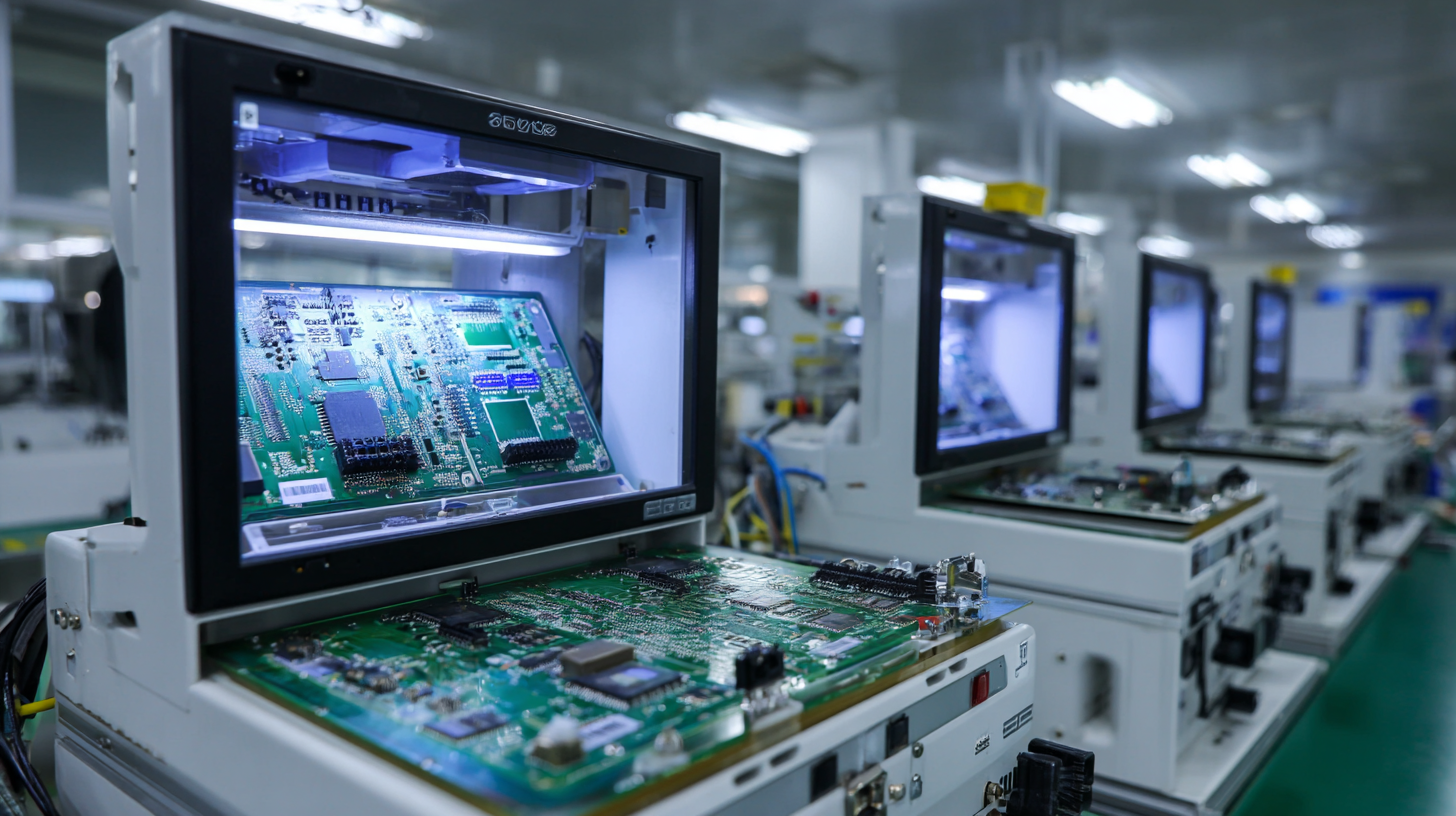

Integrating solder paste inspection machines into manufacturing lines is crucial for enhancing the reliability and efficiency of PCB assembly. Manufacturers should adopt a systematic approach when incorporating these machines into their existing processes. First, it's essential to assess the current workflow to identify optimal locations for the inspection machines, ensuring they can operate seamlessly without causing bottlenecks. This spatial consideration facilitates a smooth transition and maintains production continuity.

Moreover, training staff to use solder paste inspection machines effectively is vital. Operators should be well-versed in interpreting the inspection data and troubleshooting potential issues. Regular workshops and hands-on sessions can enhance their skills, leading to improved responsiveness and maintenance of the machines.

Establishing a feedback loop between operators and the engineering team can further refine the inspection process, leading to continuous improvements in quality and efficiency. Implementing these best practices fosters a culture of quality assurance, which is essential in today’s competitive manufacturing landscape.

Solder paste inspection (SPI) plays a critical role in the PCB assembly process, yet manufacturers often confront numerous challenges that can lead to defects. One common issue is the variability in solder paste deposition, which can result in insufficient solder for component attachment or excess solder causing bridging. According to a 2022 IPC report, defects related to improper solder paste application account for nearly 30% of assembly failures, highlighting the necessity for precise inspection methods.

Solder paste inspection (SPI) plays a critical role in the PCB assembly process, yet manufacturers often confront numerous challenges that can lead to defects. One common issue is the variability in solder paste deposition, which can result in insufficient solder for component attachment or excess solder causing bridging. According to a 2022 IPC report, defects related to improper solder paste application account for nearly 30% of assembly failures, highlighting the necessity for precise inspection methods.

To overcome these challenges, incorporating advanced solder paste inspection machines equipped with 3D measurement capabilities can be highly beneficial. These systems provide real-time feedback, allowing operators to adjust solder paste prints instantly. Additionally, maintaining proper training for staff on SPI technology can significantly reduce errors.

Tips: Regular maintenance of inspection machines is crucial to ensure their accuracy and reliability. Implementing a proactive monitoring system can help detect issues before they escalate, leading to cost savings and enhanced production efficiency. Moreover, using automated defect reporting systems can streamline the feedback loop, ensuring rapid responses to any solder paste discrepancies.

The advancement of solder paste inspection technology is critical for enhancing manufacturing efficiency in PCB assembly. According to a report by MarketsandMarkets, the global solder paste inspection market is projected to reach USD 1.2 billion by 2025, growing at a CAGR of 8.5% from 2020. As manufacturing processes become increasingly automated, the need for precise and reliable inspection systems to detect defects in solder paste application is paramount. Innovations in 3D inspection technology are enabling manufacturers to capture and analyze data with unprecedented accuracy, leading to improved yield rates and reduced rework.

Future trends suggest a shift towards integrated inspection solutions that not only evaluate solder paste quantity and distribution but also correlate this data with overall manufacturing metrics. Industry experts emphasize the importance of real-time data analytics, which can lead to proactive decision-making and further optimize production lines. It is expected that these advancements will not only streamline the PCB assembly process but also contribute to the broader goals of Industry 4.0, where interconnected systems drive operational efficiency and quality assurance. The adoption of AI and machine learning in inspection processes will likely further enhance capabilities, enabling manufacturers to stay competitive in a rapidly evolving market.