-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

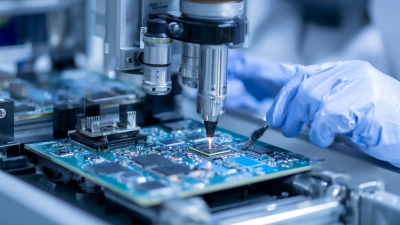

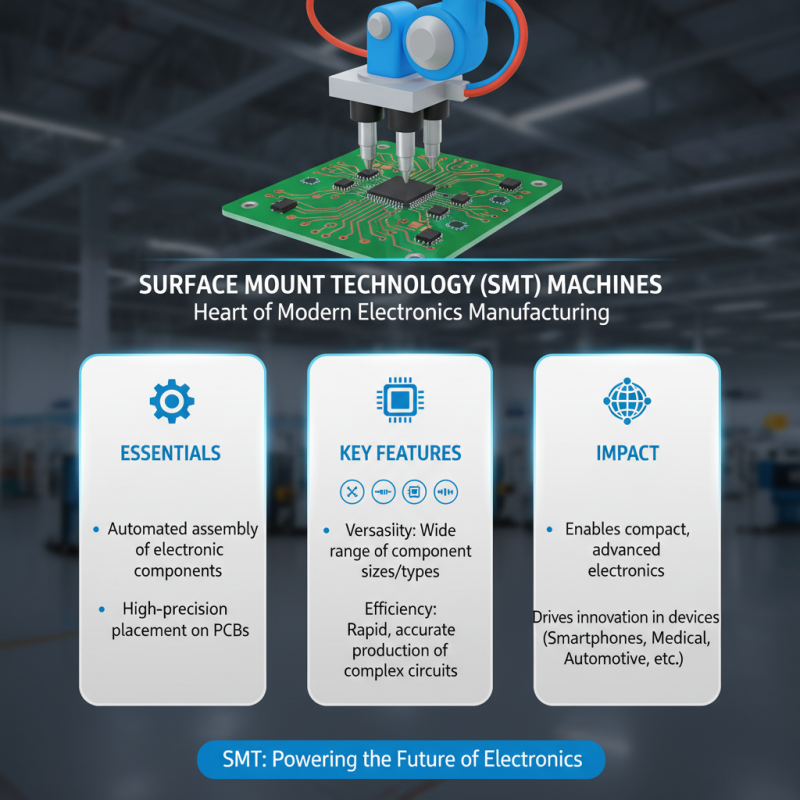

In the fast-evolving landscape of modern manufacturing, efficiency and precision are paramount. One of the pivotal technologies driving these advancements is Smt Machines, or Surface Mount Technology machines. These sophisticated devices have revolutionized the way electronic components are assembled and integrated into circuit boards. As industries strive to meet the increasing demand for miniaturized and high-performance electronics, understanding the various types and benefits of Smt Machines becomes essential.

Smt Machines come in diverse forms, each tailored to specific manufacturing needs. From pick-and-place machines to stencil printers and reflow ovens, these tools collectively enhance the production process by minimizing errors and maximizing throughput. This introduction to Smt Machines serves not only to highlight their fundamental roles but also to delve into their advantages, such as improved reliability and reduced production times. As manufacturers continue to adopt innovative technologies, the significance of mastering Smt Machines will play a crucial role in staying competitive in the global market.

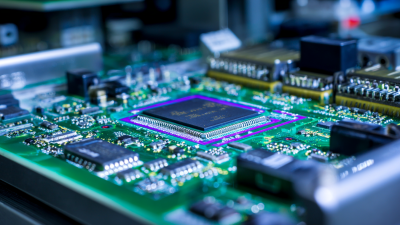

Surface Mount Technology (SMT) machines are essential tools in modern electronics manufacturing, designed to place surface mount components onto printed circuit boards (PCBs). These machines automate the process of soldering electronic components, which significantly enhances production speed and accuracy. According to a report by ResearchAndMarkets, the global SMT machine market was valued at approximately $3.5 billion in 2022 and is projected to reach around $5.5 billion by 2027, indicating robust growth as industries increasingly adopt automated solutions.

SMT machines come in various types, including pick-and-place machines, printers, and reflow ovens, each serving a specific function in the assembly process. Pick-and-place machines, for example, are capable of placing thousands of components per hour, optimizing throughput while reducing labor costs. Additionally, the shift towards compact and efficient electronic devices has fueled the need for advanced SMT technologies, as highlighted in a study by MarketsandMarkets, which suggests that the demand for SMT equipment in the automotive and telecommunications sectors is on the rise. As manufacturers embrace these innovations, they are better positioned to meet the evolving demands of the market while ensuring the highest levels of precision and reliability in their products.

Surface Mount Technology (SMT) machines are integral to modern manufacturing, especially in the electronics sector. They facilitate the placement of electronic components on printed circuit boards (PCBs) with precision and speed. Various types of SMT machines cater to different manufacturing needs, including pick-and-place machines, reflow ovens, and screen printers, each specializing in distinct aspects of the assembly process.

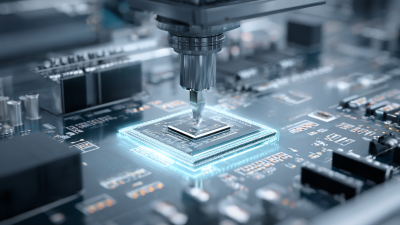

Pick-and-place machines are the backbone of SMT assembly, adept at handling a wide assortment of components, from tiny resistors to larger capacitors. These machines utilize sophisticated camera systems for accurate positioning and can operate at high speeds, which significantly enhances production efficiency. Reflow ovens, on the other hand, are crucial for soldering components onto PCBs after placement, using controlled heating to ensure optimal soldering without damaging sensitive parts. Screen printers play a vital role in applying solder paste onto the boards, paving the way for effective component attachment.

Tips: For manufacturers looking to enhance their SMT processes, investing in automation can yield substantial benefits in production speed and accuracy. Regular maintenance of SMT machines ensures consistent performance and longevity. Additionally, proper training for operators can minimize errors and improve overall efficiency in the manufacturing line.

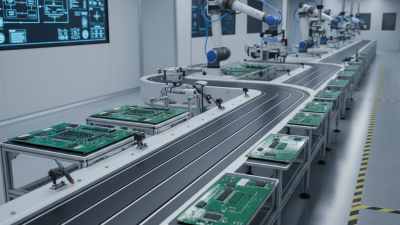

Surface Mount Technology (SMT) machines play a crucial role in modern manufacturing by streamlining production processes and enhancing efficiency. One of the primary benefits of using SMT machines is their ability to significantly increase the density of electronic components on circuit boards. According to a report by IPC, the Electronics Manufacturing industry has seen a shift towards SMT, which now accounts for over 80% of all PCB assembly processes. This rise can be attributed to SMT's capacity for miniaturization and the superior electrical performance of surface-mounted components.

Moreover, SMT machines reduce the need for manual labor, thereby lowering production costs and minimizing human error. With automated systems, manufacturers can achieve higher speeds and precision, resulting in a marked increase in productivity. A study by Deloitte shows that companies utilizing SMT can improve their output rates by up to 50%, allowing for quicker response times to market demands.

Tips: When selecting an SMT machine, consider the machine's speed and compatibility with various component sizes to ensure that it meets your production needs. Regular maintenance of these machines is also essential to maintain optimal performance and minimize downtime. Additionally, investing in training for your workforce can maximize the benefits of these advanced machines, leading to more efficient production runs and improved product quality.

SMT (Surface Mount Technology) machines are essential in modern manufacturing, particularly in the electronics sector. These machines facilitate the precise placement of electronic components onto printed circuit boards (PCBs), which is crucial for the assembly process. One of the key features of SMT machines is their ability to handle a wide range of component sizes and types, from tiny resistors to larger capacitors. This versatility allows manufacturers to produce complex circuitry efficiently.

Another significant feature of SMT machines is their automated pick-and-place capability. This function not only enhances speed and accuracy but also reduces labor costs and human error. Advanced models are equipped with vision systems that ensure precise alignment of components before placement, further improving reliability. Additionally, many SMT machines integrate soldering and inspection processes, streamlining production and minimizing the need for additional equipment. These features collectively contribute to increased productivity and enhanced quality control in the manufacturing workflow.

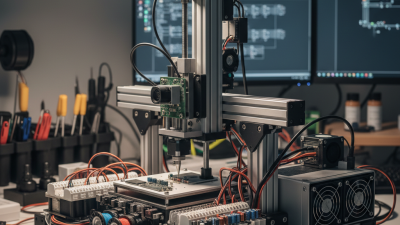

The future of Surface Mount Technology (SMT) is poised for significant advancements, driven by increasing demands for more compact and efficient electronic devices. As manufacturers strive to enhance productivity and reduce costs, the integration of Artificial Intelligence (AI) and machine learning into SMT processes is becoming more prevalent. These technologies can optimize manufacturing workflows, enabling real-time monitoring and adaptive adjustments to improve yield rates. Additionally, AI-driven predictive maintenance can minimize equipment downtime, ensuring smoother operations.

Moreover, the trend towards miniaturization in electronics is pushing the development of more sophisticated SMT machines. Innovations such as advanced pick-and-place robots and high-precision soldering equipment are becoming essential. Furthermore, the rise of the Internet of Things (IoT) is leading to the creation of smarter SMT systems that can communicate and share data across networks. This interconnectedness allows manufacturers to track performance metrics and quality control in real-time, promoting greater efficiency and agility in response to market demands. As the industry evolves, embracing these trends will be crucial for companies aiming to maintain competitiveness in the fast-paced electronics market.

| Type of SMT Machine | Function | Key Benefits | Current Trends |

|---|---|---|---|

| Pick and Place Machine | Automatic placement of components onto PCBs | High efficiency, precision placement, reduced labor costs | Automation, AI integration |

| Screen Printer | Applying solder paste onto printed circuit boards | Consistency in paste application, reduction in defects | 3D inspection systems, advanced stencil technologies |

| Reflow Oven | Heating and melting solder paste to form connections | Uniform heating, improved solder joint quality | Energy efficiency, lead-free soldering techniques |

| Automated Optical Inspection (AOI) | Inspection of PCBs for defects | Early detection of defects, higher yields | Machine learning, advanced imaging technologies |