-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

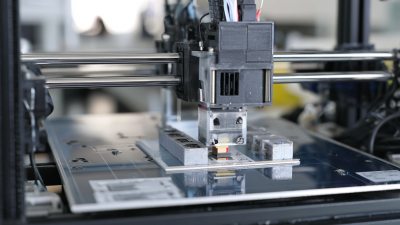

In the world of electronics manufacturing, the Solder Paste Printer plays a crucial role. This machine is essential for applying solder paste to printed circuit boards (PCBs). According to industry expert John Thompson, "A well-calibrated Solder Paste Printer can make a significant difference in production quality." His insights underline the importance of precision in this process.

The workings of a Solder Paste Printer involve multiple steps. During operation, it utilizes a stencil to apply solder paste with accuracy. This method ensures that each connection point is precisely covered. However, achieving optimal performance can be challenging. Calibration errors or stencil alignment issues may lead to defects. These imperfections can cause solder problems later in the assembly process.

Understanding the nuances of a Solder Paste Printer is vital for manufacturers. While the technology has advanced significantly, continuous improvement is needed. Each printer offers unique features, yet the quest for quality remains a common goal. A better grasp of this equipment can empower professionals to refine their production techniques.

Solder paste is a crucial material in electronics manufacturing. It is a mixed substance of solder and flux, essential for connecting components to printed circuit boards (PCBs). The paste has a thick, sticky consistency that allows it to stay in place during the assembly process. When heated, it melts and creates a strong electrical and mechanical bond.

The importance of solder paste cannot be overstated. It ensures reliable connections between tiny components and the PCB. A well-applied solder paste can enhance the performance of electronic devices. However, improper application can lead to defects. Too much solder can cause bridging, while too little can result in weak joints.

Manufacturers often invest in solder paste printers for accuracy. This equipment applies the paste precisely, limiting defects. Yet, even the best machines can face issues. Misalignment during the printing process can lead to errors. Operators must monitor the process closely to maintain quality. It is a balance of technology and human oversight, and room for improvement always exists.

| Dimension | Description |

|---|---|

| Definition | A device used to apply solder paste onto printed circuit boards (PCBs). |

| Function | To ensure accurate and consistent application of solder paste for the assembly process. |

| Components | Includes stencil, squeegee, and paste holder. |

| Types | Manual, semi-automatic, and fully automatic printers. |

| Importance of Solder Paste | Critical for creating reliable electrical connections and ensuring product quality. |

| Process Steps | Setup, Paste application, Inspection, and Cleaning. |

| Common Issues | Incomplete coverage, paste smearing, and alignment errors. |

| Maintenance | Regular cleaning of stencils and squeegees to prevent contamination. |

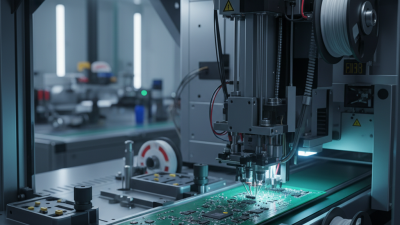

Solder paste printers play a crucial role in electronics manufacturing. Their primary function? Applying solder paste accurately to printed circuit boards (PCBs). These machines must be designed with precision in mind, ensuring a consistent layer of paste. This layer is essential for creating strong solder joints during assembly.

The design of solder paste printers varies based on specific needs. Many feature a stencil-based system. This allows for precise paste application through openings that are shaped exactly like the PCB pads. User-friendly controls are vital, enabling quick adjustments. Some machines also include vision systems. These systems inspect paste placement, enhancing quality control.

Yet, challenges persist in the design and operation. Misalignment can lead to defects. A poorly designed stencil can result in uneven paste application. Calibration is sometimes overlooked, impacting overall performance. Continuous reflection on these design aspects can significantly improve the reliability of solder paste printers. The pursuit of an ideal design remains an ongoing journey in the industry.

The chart above illustrates the usage trends of solder paste printers across different production types in 2023. High volume production leads with 55%, indicating a strong preference for automated processes in mass manufacturing.

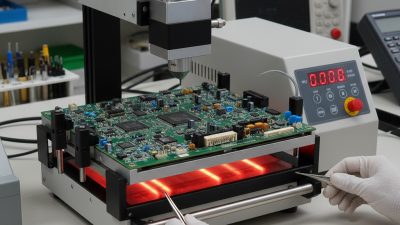

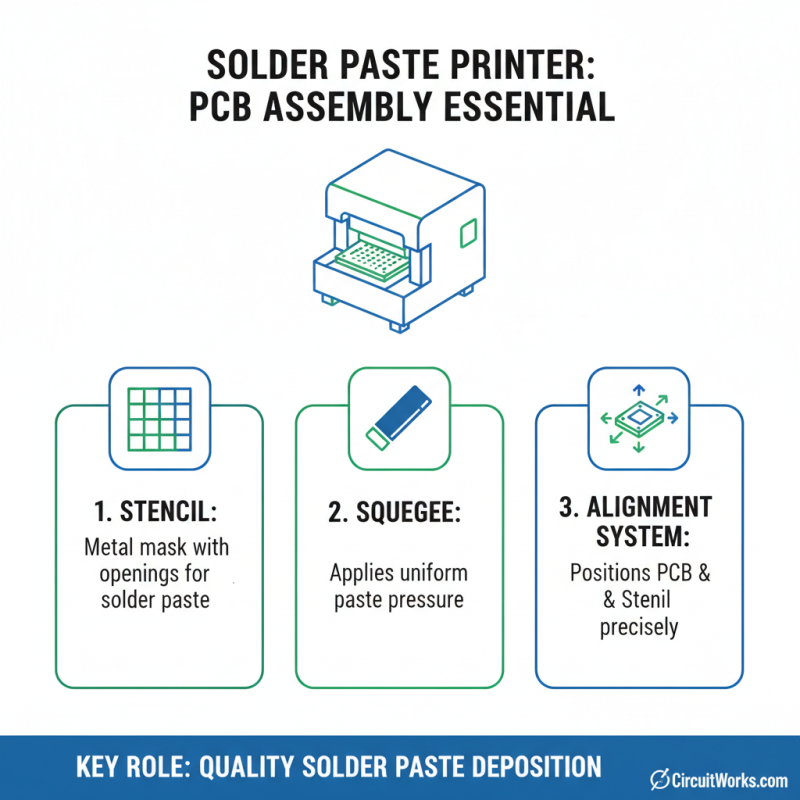

A solder paste printer is essential in the PCB assembly process. It ensures precise application of solder paste onto circuit boards. Key components of this device include the stencil, squeegee, and alignment system. Each plays a critical role in determining the quality of solder paste deposition.

The stencil holds the solder paste and controls its release. It must be made from robust materials to endure multiple uses. Research indicates that high-quality stencils increase yield rates by up to 30%. The squeegee is equally important—it applies pressure to evenly spread the paste. A well-calibrated squeegee can drastically reduce excess paste errors, which often lead to defects in soldering.

The alignment system ensures that the stencil aligns perfectly with the PCB. Misalignment can result in improper paste placement, causing electrical failures. Industry data shows that misaligned prints can lead to rework rates as high as 25%. Frequent calibration and maintenance can help mitigate these issues. Overall, while solder paste printers are crucial, they require constant attention to detail and regular upgrades to maintain optimal performance.

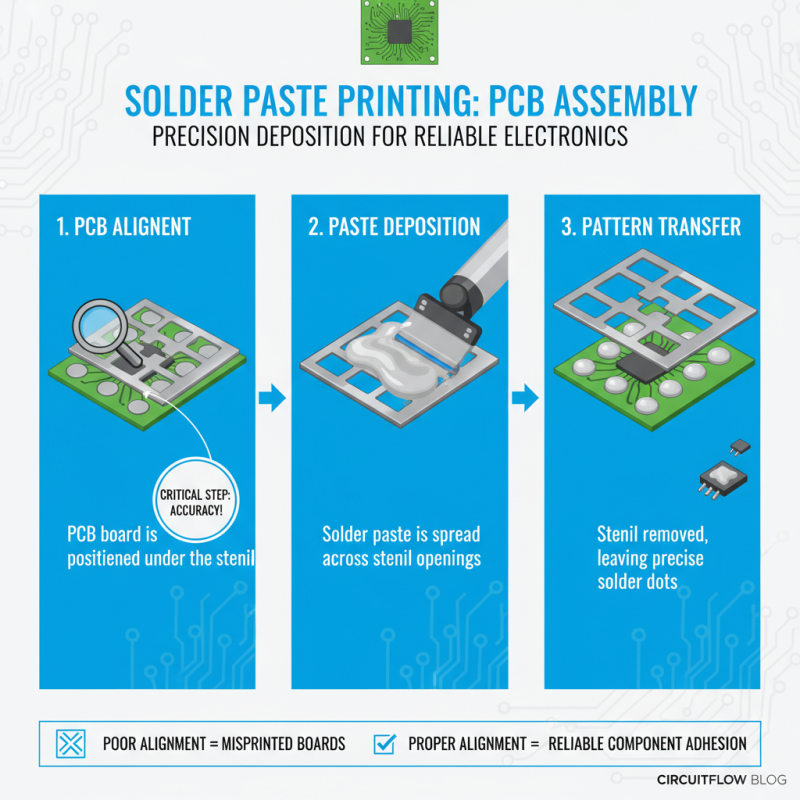

Solder paste printers play a critical role in PCB assembly. They deposit solder paste onto circuit boards, ensuring components adhere properly. The process begins with the PCB being aligned with a stencil. The stencil has openings where the solder will go. This alignment must be precise. Poor alignment can lead to misprinted boards.

After alignment, a squeegee spreads solder paste over the stencil. The paste fills the openings, transferring to the board beneath. This step is crucial. A study found that 47% of assembly defects arise from solder paste application errors. It shows the importance of accuracy. Inconsistent paste thickness can lead to issues during soldering or component placement.

**Tips:** Always check the stencil for wear or damage. A worn stencil can lead to uneven paste distribution. Clean the board surface before printing to enhance adhesion. Regular maintenance of printers is vital. It can help avoid costly repairs.

Finally, after the paste is applied, the stencil is lifted off neatly. If there are issues, they should be assessed immediately. Insufficient paste may result in weak connections. Quality checks after printing are essential for a successful assembly process. Detecting and fixing errors early can save time and materials.

Solder paste printers are essential in PCB assembly. They apply solder paste precisely onto printed circuit boards. This paste helps components adhere properly during soldering. One key benefit is improved accuracy. It minimizes the risk of misalignment in components.

Tips: Always calibrate the printer before each run. This ensures consistent results. Also, regularly clean the stencil to avoid contamination. Any residue can lead to defects.

Using a solder paste printer enhances efficiency. It speeds up the assembly process, saving time and labor costs. This is crucial in high-production environments. While it greatly reduces human error, mistakes can still happen. Operators must monitor the process carefully.

Tips: Training for operators is vital. Understand the machine's capabilities and limitations. Always perform routine maintenance to keep everything running smoothly.