-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

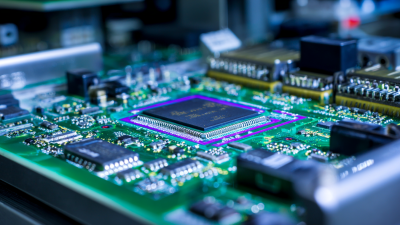

In the ever-evolving landscape of modern electronics, Surface Mount SMT (Surface Mount Technology) has emerged as a critical lifeline, enabling manufacturers to cope with the increasing demands for smaller, more efficient devices. According to a recent report by the IPC — Association Connecting Electronics Industries, the adoption of SMT technology has skyrocketed, with over 80% of new electronic assemblies utilizing this method. By allowing components to be mounted directly onto the surface of printed circuit boards, Surface Mount SMT not only conserves space but also enhances performance and reliability.

Dr. Alex Thompson, a leading expert in SMT manufacturing, emphasizes the transformative power of this technology, stating, "Surface Mount SMT has revolutionized the way we design and build electronic devices, pushing the boundaries of innovation in every sector." The flexibility and efficiency offered by SMT are pivotal for addressing the complexities of modern electronics, ranging from consumer products to advanced medical devices. As we delve into the top 10 benefits of Surface Mount SMT technology, it becomes evident that its integration into electronics manufacturing is not just a trend, but a necessity for achieving competitive advantage in today's fast-paced market.

Surface Mount Technology (SMT) has revolutionized the way compact electronic devices are designed, enabling manufacturers to create smaller, more efficient products. One of the key benefits of SMT is its ability to maximize space on printed circuit boards (PCBs). According to a recent report by the IPC (Association Connecting Electronics Industries), SMT components can reduce the board area required by up to 50% compared to through-hole technology. This significant space-saving allows for the integration of advanced functionalities without increasing the size of the device.

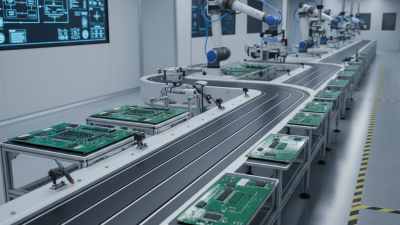

Moreover, SMT contributes to process efficiency, which is crucial in modern electronics manufacturing. The design of SMT components facilitates automated assembly, resulting in faster production times and lower labor costs. Research from the Electronic Industry Association indicates that companies employing SMT can experience a reduction in production costs by as much as 30%. This not only enhances the overall productivity of manufacturing processes but also improves product reliability due to fewer handling steps.

Tips: When designing compact electronics, consider utilizing double-sided PCBs to further optimize space. Additionally, make sure to evaluate the thermal management aspects of SMT, as densely packed components may require advanced heat dissipation techniques to ensure reliable operation. Lastly, keep in mind that standardizing component sizes can simplify the assembly process, making it easier to scale production while maintaining quality.

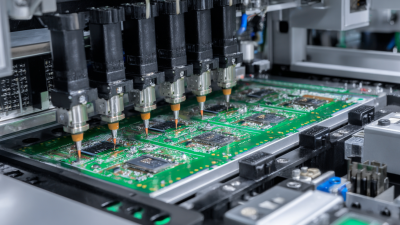

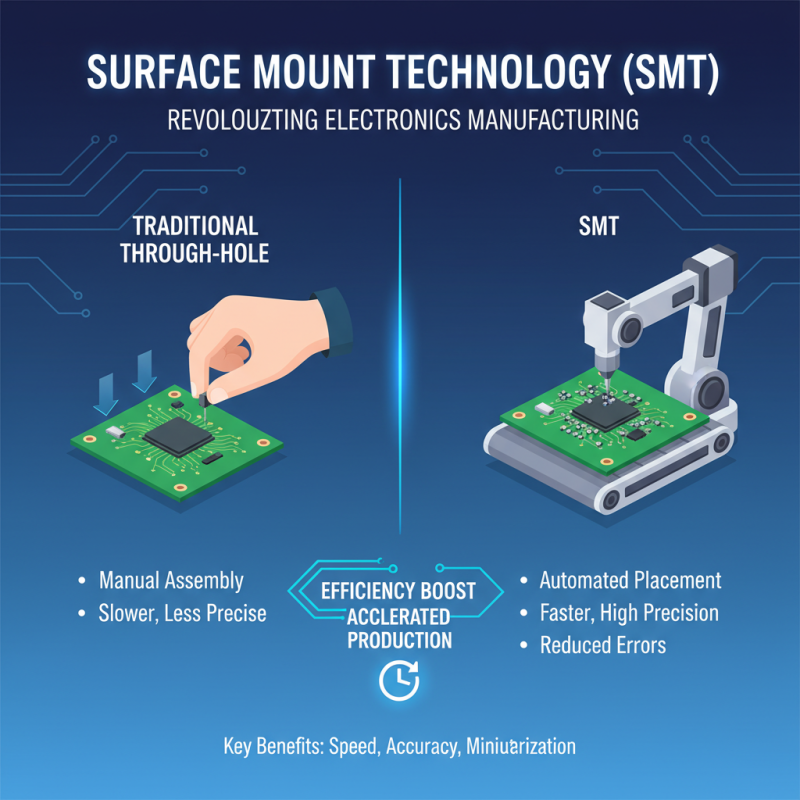

Surface Mount Technology (SMT) has revolutionized the manufacturing process in the electronics industry, significantly enhancing efficiency. Unlike traditional through-hole technology, SMT allows components to be mounted directly onto the surface of printed circuit boards (PCBs). This method reduces the time and labor involved in assembly, as components can be placed more quickly and with greater precision. Automated placement machines can handle thousands of components per hour, streamlining production lines and minimizing the risk of human error, thus further accelerating the manufacturing process.

Moreover, SMT facilitates higher component density on PCBs due to its compact design. Manufacturers can optimize the layout of their circuits, leading to smaller and lighter products that meet the demands of modern consumer electronics. The reduced footprint not only saves materials and costs but also allows for more intricate designs, enabling the integration of advanced features in smaller devices. With improved efficiency and enhanced design capabilities, SMT stands at the forefront of innovation in electronics manufacturing, driving the industry towards greater productivity and technological advancement.

Surface Mount Technology (SMT) has revolutionized the electronics industry, particularly in enhancing electrical performance. One of the pivotal advantages of SMT components lies in their reduced size and weight, which directly contributes to improved electrical characteristics. According to a report by IPC, PCBs that utilize SMT can achieve a significant reduction in inductance and capacitance values compared to traditional through-hole components. This is critical in high-frequency applications, where minimizing signal loss and interference is paramount. As components get smaller and placed closer together, the electromagnetic interference (EMI) can be drastically reduced, leading to cleaner signals and enhanced overall device performance.

Moreover, the thermal management capability of SMT components is superior, allowing for efficient heat dissipation. Research published in the IEEE Transactions on Components, Packaging and Manufacturing Technology highlights that SMT assemblies can operate at higher temperatures without compromising performance. This resilience is vital for modern electronics, particularly in environments with fluctuating temperatures or in high-powered applications. The innovative designs of SMT components also enable denser circuit layouts, which can accommodate advanced functionalities without increasing the form factor of devices. Collectively, these improvements underpin the transition towards more efficient, compact, and high-performing electronic systems, meeting the increasing demands of today's technology landscape.

| Benefit | Description | Impact on Performance |

|---|---|---|

| Space Efficiency | SMT components are smaller than through-hole counterparts, allowing for more compact designs. | Enables smaller devices with the same or improved functionality. |

| Higher Component Density | Allows placing components on both sides of the PCB. | Increases design complexity but boosts performance with less material. |

| Improved Reliability | Reduced mechanical stress on joints due to lower profiles and less solder. | Higher lifecycle reliability and reduced failure rates. |

| Lower Production Costs | Faster assembly processes reduce labor costs. | Affects bottom line positively through economies of scale. |

| Enhanced Performance | Better electrical performance with shorter signal paths. | Improves signal integrity and reduces impedance. |

| Automated Assembly | Integration with automated pick and place machines streamlines production. | Accelerates time-to-market and reduces human error. |

| Increased Frequency | SMT components can operate at higher frequencies due to their low inductance. | Enables advanced applications such as RF and high-speed digital circuits. |

| Thermal Performance | Better heat dissipation through lower thermal resistance. | Extends the life of components by maintaining optimal operating temperatures. |

| Flexibility in Design | Facilitates complex layouts and innovative designs. | Improved aesthetics and functionality in electronic products. |

| Global Standards Compliance | Standardization in SMT design leads to better compliance. | Minimizes regulatory roadblocks and enhances market access. |

Surface Mount Technology (SMT) has emerged as a transformative force in the production of modern electronics, primarily due to its cost-effective solutions. By allowing components to be mounted directly onto the surface of printed circuit boards (PCBs), manufacturers can significantly reduce assembly time and material costs. The elimination of through-holes in traditional methods not only saves space but also minimizes the number of raw materials required, leading to a more streamlined production process.

Moreover, SMT enhances manufacturing efficiency by enabling the integration of more components in a smaller footprint, which is crucial for today’s compact electronic devices. As a result, manufacturers can optimize their production lines and respond faster to market demands. The shorter production cycles also translate into reduced labor costs, making SMT an economically viable option for companies looking to innovate without breaking the bank.

Tips: When considering SMT for your projects, ensure you invest in high-quality equipment to maintain precision during assembly. Additionally, regularly train your staff on the latest SMT techniques to keep up with industry standards and leverage their expertise for better results. Adopting good design practices from the start can also mitigate issues down the line and enhance overall efficiency.

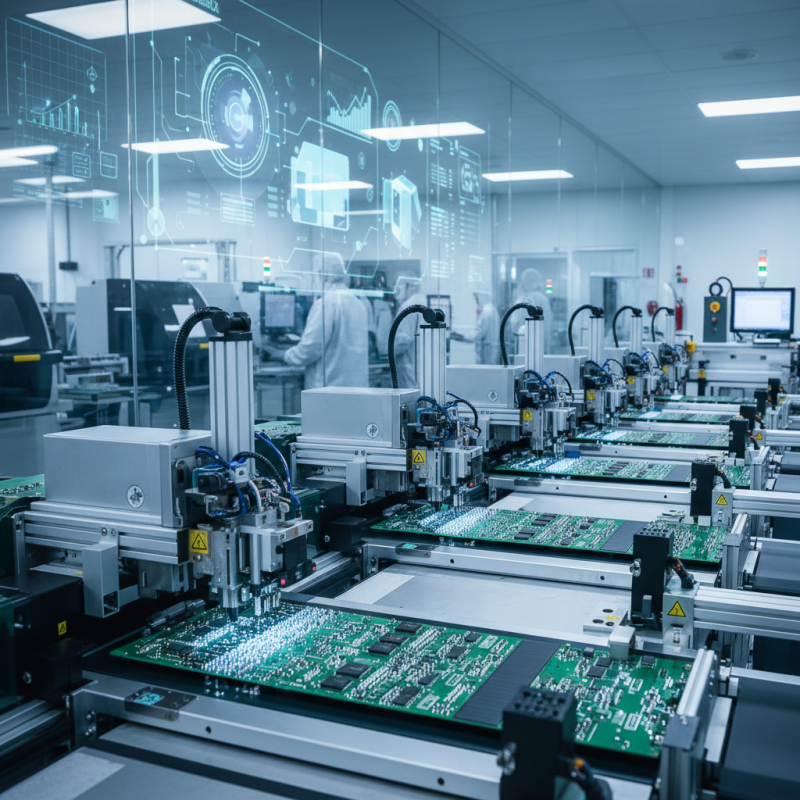

Surface Mount Technology (SMT) has revolutionized the design flexibility of modern electronics, allowing engineers to push the boundaries of innovation. One of the primary advantages of SMT is its ability to accommodate a wide variety of circuit layouts and component shapes. This flexibility enables designers to create more compact and complex electronic devices, which are essential in today’s market that demands both miniaturization and functionality. With SMT, components can be placed on both sides of a printed circuit board (PCB), maximizing space utilization and enabling intricate designs that were previously challenging with traditional through-hole methods.

Additionally, SMT supports a diverse range of components, from tiny chip resistors to large power modules, giving designers the freedom to select the most appropriate parts for their specific application. This adaptability not only enhances the operational efficiency of devices but also makes it easier to modify designs rapidly in response to changing requirements or new technologies. The integration of SMT has led to faster prototyping and reduced time-to-market for electronic products, empowering manufacturers to respond more agilely to consumer demands and industry trends. Ultimately, the greater design flexibility offered by Surface Mount Technology is a driving force behind the evolution of modern electronics, fostering creativity and innovation across a wide array of applications.