-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

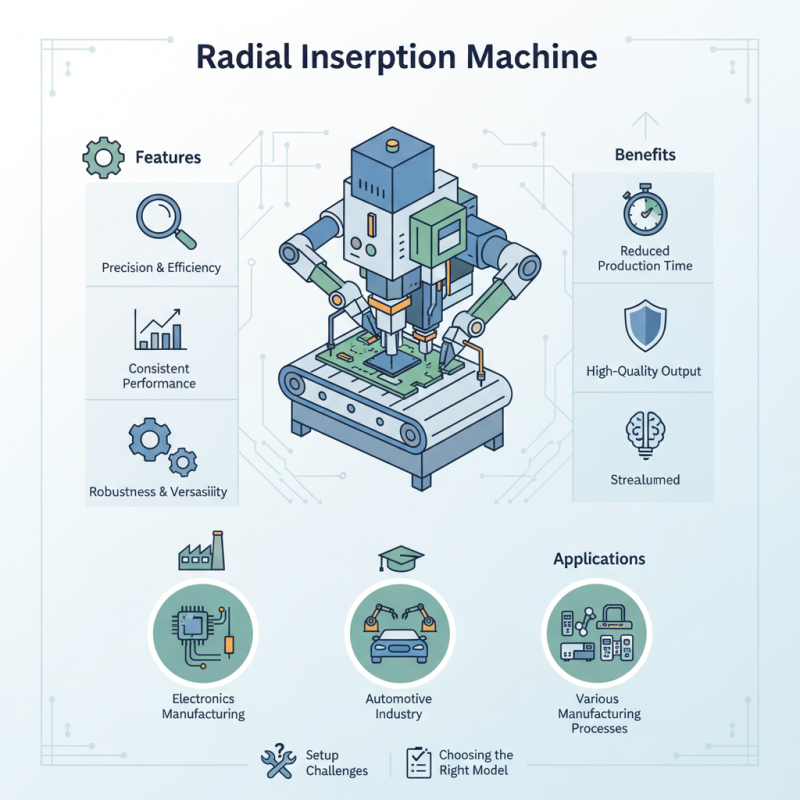

The Radial Insertion Machine plays a crucial role in modern manufacturing. Its design facilitates precision and efficiency, critical in today’s competitive market. According to a 2022 report by Smith & Associates, the global demand for automation in production has surged by 25%. This growth highlights the importance of machines like the Radial Insertion Machine, which streamline assembly processes.

In sectors such as electronics and automotive, reliability is paramount. The Radial Insertion Machine offers consistent performance, ensuring high-quality outputs. Industry studies indicate that companies using advanced insertion technology see a 30% reduction in production time. Yet, challenges remain. Some operators may struggle with setup, leading to potential downtime. Workers need proper training to maximize productivity.

Emphasizing robustness and versatility, this machine adapts to various applications. It caters to the intricate needs of different manufacturing processes. However, choosing the right model can be daunting, and not all machines deliver the promised benefits. A thoughtful approach to selecting and implementing a Radial Insertion Machine can yield significant dividends for manufacturers.

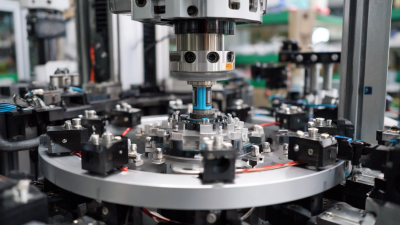

Radial insertion machines serve numerous industries. These machines are crucial for inserting components like pins or connectors. Key features include precision placement and high speed. They can automate tasks that are often manual and time-consuming. By doing so, productivity increases significantly.

These machines are designed for flexibility. Operators can adjust settings easily. This adaptability allows for various components to be handled. Less downtime for changeovers is a major benefit. However, this requires some initial training. Operators must understand the settings clearly to avoid errors.

Another advantage is the compact design. These machines can fit into smaller workspaces. This is beneficial for companies with limited floor space. But, one needs to consider maintenance. Regular checks ensure reliability and performance. Overlooking this can lead to unexpected downtime. Fluent operation depends on addressing these needs proactively.

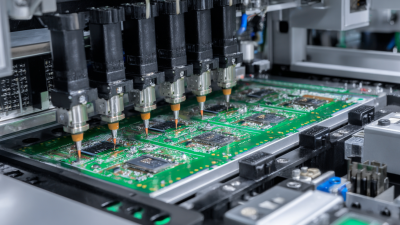

Radial insertion machines are transforming production lines across various industries. One major benefit is increased efficiency. These machines can insert components rapidly, often exceeding 1,200 parts per hour. This speed allows manufacturers to meet high demands without sacrificing quality. A report from the Manufacturing Institute states that companies utilizing such machines see productivity improvements of up to 30%.

Another advantage lies in precision. Radial insertion machines minimize human error, ensuring that components are placed accurately every time. Statistics reveal that automation reduces defects by nearly 50%. This leads to lower scrap rates and higher profit margins. It's clear that investing in these machines pays off in the long run.

**Tip:** Regular maintenance is essential. Without it, even the best machines can falter. Inspecting parts weekly can prevent costly downtimes. Reflections on training staff are crucial as well. Even top-tier machines require skilled operators for optimal performance. Ultimately, human oversight and machine efficiency must work hand in hand.

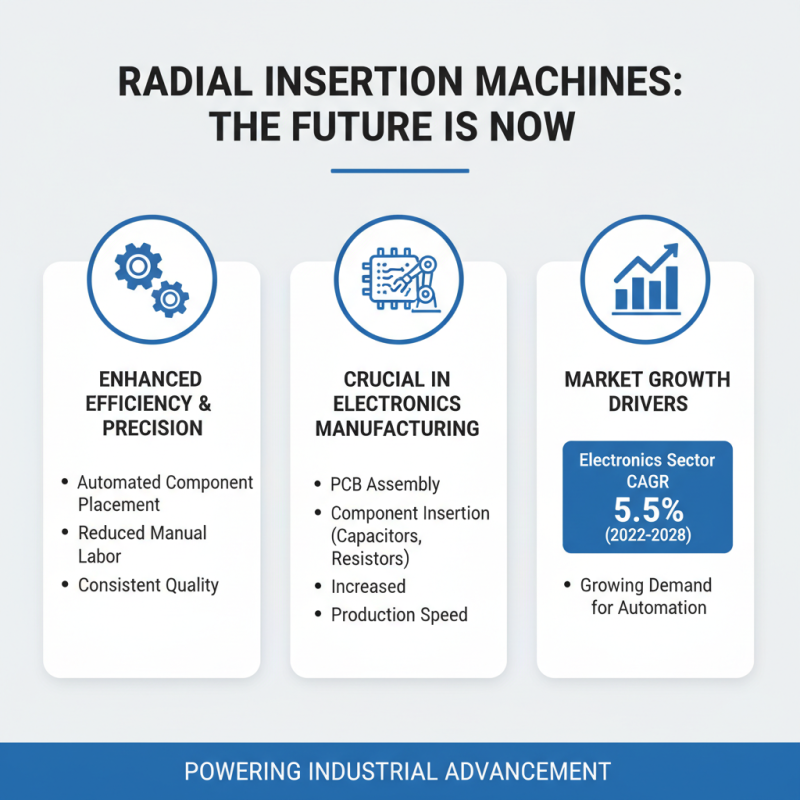

Radial insertion machines are becoming crucial in various industries. They offer enhanced efficiency and precision. In electronics, these machines handle tasks like inserting components into PCBs. Reports indicate that the electronics sector is projected to grow at a CAGR of 5.5% from 2022 to 2028, driving demand for efficient insertion technologies.

In the automotive industry, radial insertion machines play a key role. Specifically, they assist in the assembly of wiring harnesses. The global automotive manufacturing market reached over $2 trillion in 2021. As the industry shifts towards electric vehicles, the need for reliable insertion machines escalates. This trend highlights the importance of adapting to evolving market demands.

**Tips:** Regular maintenance of machinery ensures consistent performance. Inspecting insertion accuracy can prevent costly errors. Consider training operators thoroughly to maximize machine capability. The margins for error are slim. Overlooking small details can lead to significant setbacks in production. It’s a reminder to always prioritize accuracy.

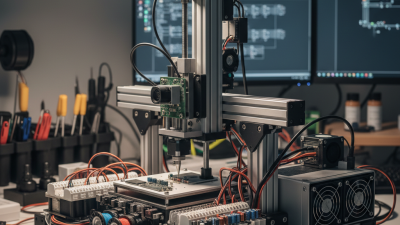

When evaluating different models of radial insertion machines, several unique features stand out. Some machines focus on speed, reducing cycle time significantly. Others prioritize precision, using advanced sensors for exact component placement. These features impact efficiency, but users must consider their specific needs. Speed is great for high-volume production. However, it might sacrifice precision, affecting overall quality.

Different models also vary in ease of use. Some machines come with user-friendly interfaces. Operators require less training, increasing productivity. Conversely, more advanced machines can be complicated. These may require technical knowledge that not all staff possess. Balancing user-friendliness with advanced options is essential for manufacturers.

Another consideration is adaptability. Some machines can handle various component sizes and types. This flexibility can lead to cost savings. In contrast, others are dedicated to specific tasks, limiting their applications. Such machines often underperform when faced with unexpected tasks. Manufacturers should evaluate their long-term vision when choosing a model. The right machine can streamline operations. However, the wrong choice could lead to inefficiencies and increased costs down the line.

| Model | Insertion Speed (items/min) | Max Insert Depth (mm) | Precision (% deviation) | Applications | Unique Features |

|---|---|---|---|---|---|

| Model A | 120 | 30 | 0.01 | Electronics Assembly | Automatic Feed System |

| Model B | 100 | 25 | 0.02 | Automotive Parts | User-Friendly Interface |

| Model C | 150 | 35 | 0.005 | Medical Devices | High Throughput |

The future of radial insertion machine technology promises exciting advancements. As industries demand more efficient solutions, these machines are evolving. Innovations focus on automation and smart features. Integrating AI can streamline processes significantly. For instance, machines may start using machine learning to optimize performance based on real-time data.

Sustainability is another key trend shaping the future. Energy-efficient designs will likely become standard. Machines that minimize waste during operations will gain traction. However, not all designs are perfect. Some may struggle to balance complexity and efficiency. User feedback mechanisms will be crucial to improving performance.

Moreover, connectivity is essential. Machines that communicate with each other can improve workflow. This interconnectedness can lead to enhanced productivity. Yet, challenges in cybersecurity may arise. Protecting sensitive data becomes vital as machines become more integrated. Companies must prioritize safety as they embrace these new technologies.