-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In the world of PCB manufacturing, efficiency is crucial. The Reflow Oven plays a key role in this process. Its importance cannot be overstated; it helps in soldering components onto printed circuit boards effectively. Different types of Reflow Ovens offer varied features and benefits.

Selecting the right Reflow Oven can significantly impact production outcomes. Manufacturers often face confusion when choosing. Each type has unique specifications, which can lead to challenges in decision-making. For example, some ovens provide better thermal control, while others support high-volume production. Yet, the best choice depends on specific production needs.

Understanding the features of each Reflow Oven type is essential for optimizing performance. One must consider factors like energy efficiency and footprint. The wrong choice can lead to inefficiencies and increased costs. In a market driven by rapid technology changes, this decision requires careful thought and analysis.

When it comes to PCB manufacturing, choosing the right reflow oven is crucial. Different types suit varying production needs. One common type is the convection reflow oven, which uses hot air to evenly heat the PCB. This ensures consistent soldering across all components, but it can be slow.

Another option is the IR (infrared) reflow oven. This type uses infrared radiation, providing faster heating. It’s effective for smaller production runs. However, the heating may not be uniform, potentially leading to solder defects.

The vapor phase reflow oven stands out for its reliability. It uses a heated vapor to achieve precise temperature control. This method minimizes thermal stress on components. Still, it can be costly and may not be suitable for all setups.

Considering these factors, it’s essential to evaluate your specific manufacturing processes and the potential trade-offs of each type.

Reflow ovens play a crucial role in PCB assembly processes. They ensure solder paste melts properly, creating reliable connections. The technology involves precise temperature control. Typically, there are different types of reflow ovens, such as convection, infrared, and vapor phase. Each type serves unique needs in manufacturing.

When using reflow ovens, maintain consistent temperature profiles. Inconsistent heating may lead to cold solder joints. These faults can compromise the entire PCB. Therefore, it’s essential to monitor temperatures closely. Regular calibration can help ensure accuracy.

Tips: Always run test boards before production. This makes identifying issues early easier. Consider using a thermal imaging camera. It helps visualize heat distribution across the PCB. Additionally, be mindful of component placement. Incorrect positioning may lead to poor reflow quality. Reflect on your reflow processes for continuous improvement.

When selecting a reflow oven for PCB manufacturing, understanding the differences between convection and infrared technologies is crucial. Convection ovens circulate hot air around the PCB, creating even heating. This method is efficient for various components, especially sensitive ones. They generally offer better temperature control across the board, which is essential for preventing issues.

Infrared ovens use radiant heat for soldering. They heat components directly, which can lead to faster soldering times. However, they may not provide the uniformity seen in convection ovens. This can be an issue if multiple component sizes are involved. Operators might need to monitor the process closely to prevent uneven heating.

Choosing between the two involves considering your specific production needs. Each type has its advantages and disadvantages. A convection oven may suit larger batches, while infrared could be a good fit for small runs. Understanding these features and their implications is key to optimizing the PCB reflow process. Remember, the best choice often requires trial and error to find what works for you.

| Reflow Oven Type | Heating Method | Key Features | Typical Applications | Cost Range (USD) |

|---|---|---|---|---|

| Convection Reflow Oven | Air Circulation | Uniform heating, Temperature profiling, Programmable | SMT Assemblies, Multi-layer PCBs | 10,000 - 75,000 |

| Infrared Reflow Oven | Infrared Radiation | Fast heating, Selective soldering, Compact design | Small batches, Quick prototyping | 5,000 - 50,000 |

| Vapor Phase Reflow Oven | Condensed vapor | Excellent thermal transfer, Suitable for complex boards | High-reliability products, Medical devices | 20,000 - 100,000 |

| Hybrid Reflow Oven | Convection + Infrared | Versatile heating, Enhanced control over profiles | Diverse PCB types, High mix production | 15,000 - 85,000 |

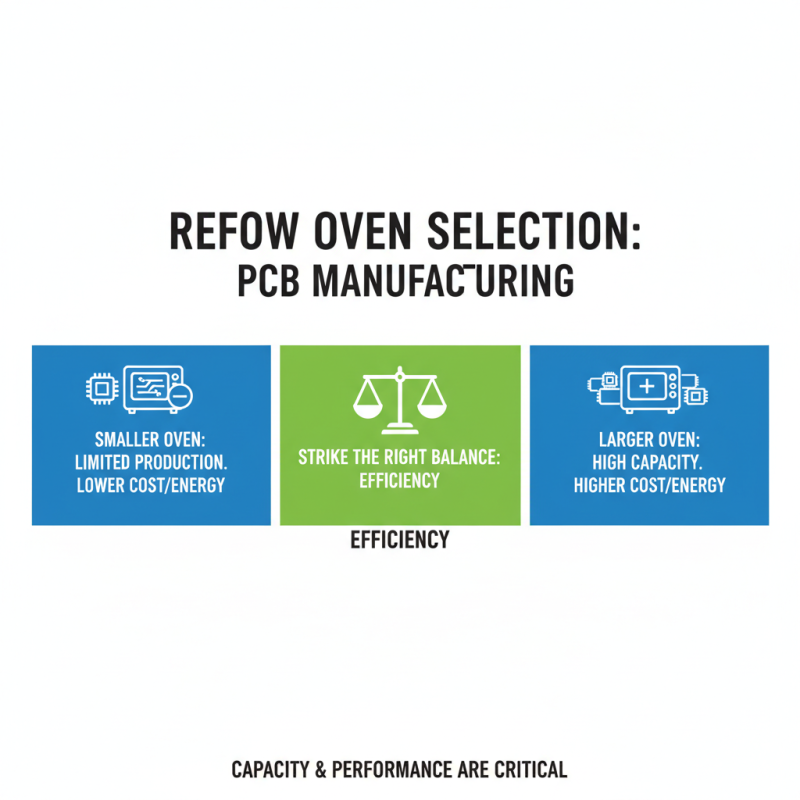

When selecting a reflow oven for PCB manufacturing, capacity and performance are critical factors. The capacity determines how many boards can be processed at once. Choosing a smaller oven may limit production. However, larger models come with higher costs and energy consumption. Striking the right balance is crucial for efficiency.

Performance metrics include temperature uniformity and heating rates. A consistent temperature across the board ensures proper soldering. If some areas heat unevenly, defects arise. Manufacturers often rely on thermocouples to monitor real-time conditions. This helps in adjusting settings promptly for optimal results.

Some challenges can emerge during evaluation. Each type of oven has its limitations, affecting productivity. For instance, a fast cycling time might not suit all components. Hence, manufacturers must reflect on their specific needs. Analyzing past production runs offers insights for future improvements. Proper evaluation can lead to better decisions and fewer mistakes.

The reflow oven plays a crucial role in PCB manufacturing. Automation and integration trends have transformed how these ovens function. Modern systems often feature advanced sensors and controls. These allow for precise temperature management and improved efficiency. Real-time monitoring ensures the process runs smoothly. However, the integration of such technology can be complex.

Many manufacturers face challenges in adopting new automation solutions. Training staff to use new equipment is essential. Misunderstandings during setup can lead to defects in PCB assembly. It's vital to assess current processes thoroughly. An integration that seems perfect might reveal issues later. Small details can make or break production quality.

As reflow ovens become smarter, manufacturers must adapt. Flexibility and constant evaluation are necessary. Technology should not overshadow the human element in operations. Balancing automation and human oversight is crucial. Some companies rush into automation without a clear strategy. This can lead to costly mistakes and wasted resources. Observing trends is important, but implementation requires careful thought.