-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

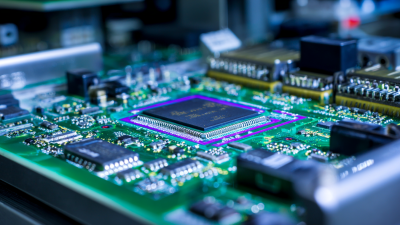

In the rapidly evolving landscape of electronics manufacturing, the demand for precision and efficiency has never been more critical. A recent report from the IPC (Institute of Printed Circuits) highlights that the global SMT (Surface Mount Technology) market is projected to reach $2.8 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.1%. This growth underscores the importance of effective SMT Placement Equipment in streamlining production processes, enhancing quality control, and reducing operational costs.

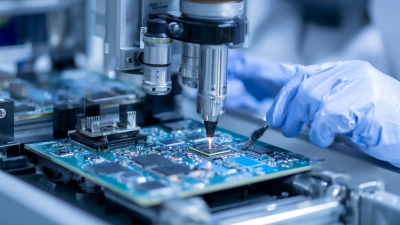

SMT Placement Equipment plays a pivotal role in ensuring that components are accurately placed on PCBs (Printed Circuit Boards), which is fundamental to the reliability and performance of electronic devices. According to a study by Gartner, companies that invest in advanced placement technology can increase their production output by up to 20%, while simultaneously minimizing material waste and defect rates. In this context, identifying the top SMT Placement Equipment becomes vital for manufacturers aiming to maintain a competitive edge in an increasingly sophisticated industry.

As we explore the top 10 SMT Placement Equipment options available today, we will discuss how these advanced tools not only meet the stringent demands of modern electronics production but also utilize cutting-edge technology to enhance operational efficiency. By leveraging these innovations, manufacturers can secure their positions in a marketplace characterized by rapid technological advancements and ever-increasing customer expectations.

When selecting the right SMT placement equipment for electronics production, the focus should be on enhancing production efficiency and ensuring precision. The complexity of modern electronics demands equipment that can handle various component types and sizes while maintaining high placement accuracy. Manufacturers should consider features like optimized vision systems, advanced algorithms, and adjustable placement speeds, which directly contribute to reducing downtime and increasing throughput.

Equally important is the equipment's compatibility with existing production lines. Evaluating the integration capabilities of new machines with existing technologies can prevent workflow disruptions. Additionally, scalability is an essential factor; as production needs evolve, having equipment that can adapt to increased demands and accommodate more sophisticated components ensures sustained efficiency. Investing in the right SMT placement equipment is not just about current production capabilities, but also future-proofing operations against rapidly changing technology demands.

| Model | Placement Speed (CPH) | Accuracy (%) | Max PCB Size (mm) | Features |

|---|---|---|---|---|

| Model A | 15000 | 99.5 | 610 x 460 | Vision System, Dual Lane |

| Model B | 12000 | 99.2 | 580 x 480 | Flexible Nozzle, Quick Changeover |

| Model C | 18000 | 99.8 | 650 x 500 | Smart Alignment, High-Density Support |

| Model D | 16000 | 99.6 | 600 x 400 | Enhanced Vision, Customizable Station |

| Model E | 14000 | 99.4 | 640 x 450 | Automated Calibration, Remote Monitoring |

| Model F | 17500 | 99.7 | 670 x 520 | AI-Powered Functions, Multi-Size Handling |

| Model G | 15500 | 99.3 | 620 x 480 | Redundant Systems, High Throughput |

| Model H | 16500 | 99.5 | 590 x 460 | Easy Maintenance, Multi-Product Configuration |

| Model I | 13000 | 99.1 | 570 x 420 | Compact Design, Quick Setup |

| Model J | 14500 | 99.4 | 600 x 450 | User-Friendly Interface, Real-Time Feedback |

When selecting Solder Mask Technology (SMT) placement equipment for electronics production, precision and efficiency are paramount. Key features to consider include the machine's placement accuracy, speed, and flexibility. According to a report by the IPC (Institute of Printed Circuits), modern SMT placement machines now achieve placement accuracy within +/- 25 microns, a critical standard for high-density applications. Such precision ensures that components are placed accurately on the PCB, minimizing rework and enhancing product reliability.

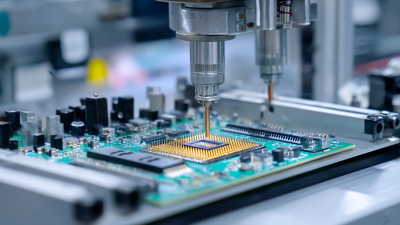

Additionally, the speed of the placement process is crucial; high-performance machines can place components at rates exceeding 100,000 components per hour. This capability allows manufacturers to meet demanding production schedules without compromising quality. Flexibility is another important aspect, as versatile machines can handle a wide range of component types and sizes, making them ideal for various production runs. A recent analysis by MarketsandMarkets highlights that 72% of manufacturers prioritize machine adaptability in their purchasing decisions, underscoring the need for equipment that can efficiently manage different project requirements.

In the competitive landscape of electronics manufacturing, achieving high precision and efficiency in Surface Mount Technology (SMT) placement equipment is crucial. Recent industry benchmarks indicate that state-of-the-art SMT equipment can achieve placement accuracy rates up to 99.7%, a significant improvement over older models, which typically range around 97%. According to a report from IPC, manufacturers utilizing advanced placement systems have reported reductions in defect rates by as much as 30%, correlating directly with enhanced operational efficiencies.

Moreover, productivity metrics have also shown promising advancements. The average throughput for modern SMT placement machines has reached approximately 20,000 components per hour, allowing manufacturers to meet the increasing demands of rapid production cycles. A 2022 survey conducted by Research and Markets highlights that 72% of electronics manufacturers attribute their production efficiency gains to the adoption of high-performance SMT equipment. This alignment with the latest technology not only boosts output but also ensures that quality standards are upheld, reinforcing market competitiveness.

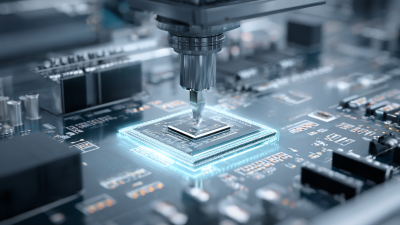

Investing in advanced SMT (Surface Mount Technology) placement equipment can significantly enhance precision and efficiency in electronics production. A recent industry report from Research and Markets highlights that the global SMT equipment market is expected to grow from $2.47 billion in 2022 to $4.76 billion by 2028, reflecting a compound annual growth rate (CAGR) of 12.25%. This growth underscores the increasing importance of high-quality SMT placement technologies for manufacturers aiming to reduce defects while optimizing production processes.

The cost-benefit analysis reveals that while the initial investment in advanced SMT machines may appear steep, the long-term savings and productivity gains justify the expenditure. For instance, a leading manufacturer, according to a study published by IPC, reported a 30% reduction in assembly time and a 25% decrease in material waste after upgrading to automated SMT placement systems. Such improvements not only contribute to higher yield rates but also enhance overall operational efficiency, ultimately leading to a stronger competitive edge in the market. With precision-driven placement capabilities, companies can respond more agilely to market demands, positioning themselves for sustained growth in the fast-evolving electronics landscape.

As we approach 2024, the landscape of Surface Mount Technology (SMT) placement equipment is set to undergo significant transformations influenced by advancements in technology and market demands. One prominent trend is the integration of artificial intelligence and machine learning into placement systems. These innovations will enhance the efficiency and precision of component placement, enabling manufacturers to reduce production downtime and improve throughput. The ability of machines to learn from past errors and optimize their processes will allow for a more adaptive response to varying assembly requirements.

Another key development on the horizon is the move towards greater automation and flexibility. Future SMT placement equipment will likely feature modular designs, making it easier for companies to scale their production capabilities and accommodate new components. As the electronics industry continues to evolve with smaller, more complex components, the demand for agile systems that can quickly reconfigure for different product lines will increase. This shift towards flexible automation will not only streamline operations but also contribute to sustainability efforts by reducing waste and energy consumption in the manufacturing process.