-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In the rapidly evolving landscape of manufacturing technology, staying ahead of the trends in SMT Placement Equipment is crucial for companies looking to enhance production efficiency and accuracy. According to Dr. Emily Chen, a leading expert in the field of surface mount technology, "The future of SMT placement equipment lies in the integration of advanced automation and artificial intelligence, which will redefine how we approach assembly processes." As we move towards 2025, understanding the emerging trends within this sector will not only empower businesses to make informed decisions but also to leverage innovative solutions that streamline operations.

The advancements in SMT Placement Equipment are not merely about enhancing speed and throughput; they encompass a wide range of technological innovations aimed at improving precision, reducing waste, and optimizing the overall manufacturing process. With the industry gradually shifting towards more sustainable practices, the trends highlighted in this overview will undoubtedly shape the future of electronics assembly. As we explore these key trends, it becomes evident that adaptability and foresight are essential for companies aspiring to maintain a competitive edge in the robust market of SMT technology.

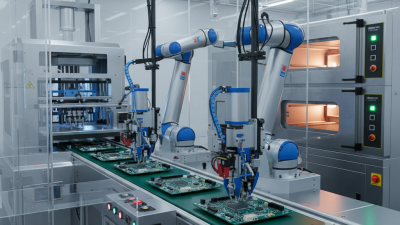

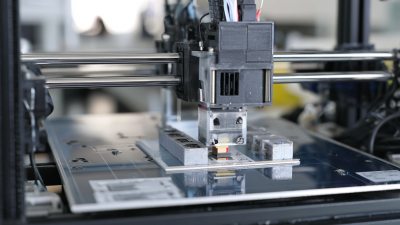

The landscape of Surface Mount Technology (SMT) placement equipment is poised for significant transformation by 2025, driven by emerging technologies that promise to enhance efficiency and precision in manufacturing. One of the key trends to watch is the increasing integration of artificial intelligence and machine learning algorithms in placement machines. These technologies enable systems to adapt to varying production conditions in real-time, optimizing the placement accuracy and speed, which is crucial for reducing cycle times and meeting the demands of high-volume manufacturing.

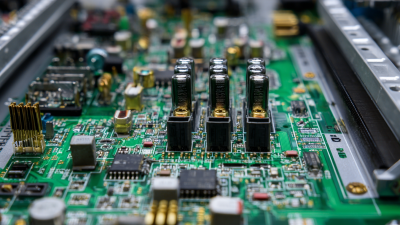

Another noteworthy development is the rise of automated quality control systems within SMT equipment. Advanced imaging and sensing technologies are being deployed to perform real-time inspections of components being placed on printed circuit boards (PCBs). This not only minimizes human error but also ensures that any defects are identified and rectified instantaneously, significantly enhancing overall manufacturing quality. Additionally, the incorporation of modular equipment designs is becoming more prevalent, allowing manufacturers to easily upgrade or reconfigure their systems to keep pace with evolving production needs and technologies. These innovations collectively signify a forward leap in SMT placement equipment, aligning with the industry's growing demand for flexibility and efficiency.

This bar chart illustrates the emerging technologies in SMT placement equipment for 2025, showcasing the expected growth in various trends such as automation, precision placement, and hybrid assembly systems.

As the electronics manufacturing landscape evolves, sustainability has emerged as a pivotal factor shaping the choices surrounding Surface Mount Technology (SMT) placement equipment. According to a recent report by the IPC (Institute for Printed Circuits), over 76% of electronics manufacturers are actively seeking more sustainable production solutions in response to growing environmental concerns. This shift is not only driven by regulatory pressures but also by the increasing demand from consumers for eco-friendly products and processes.

The industry is witnessing a marked transition towards the adoption of energy-efficient machinery and eco-conscious materials. For instance, newer SMT equipment is designed to lower power consumption, with some models boasting energy savings of up to 30% compared to their predecessors. Additionally, manufacturers are turning to recyclable and biodegradable materials to minimize waste, reflecting a commitment to circular economy principles. The increased focus on sustainability is likely to influence not just equipment choices, but also the entire supply chain, as companies prioritize suppliers that align with their environmental goals.

Moreover, innovative technologies such as IoT (Internet of Things) are being integrated into SMT equipment, enhancing not only production efficiency but also the monitoring of energy use and waste generation. A survey conducted by SEMI indicated that approximately 61% of manufacturers are exploring IoT solutions to track sustainability metrics in their operations. These advancements are critical in fostering a culture of responsibility, as they allow companies to better understand their environmental impact and make informed decisions about their production processes moving forward.

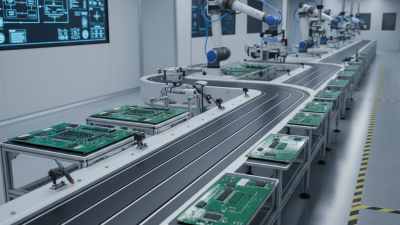

The landscape of surface-mount technology (SMT) is undergoing significant transformation due to advancements in automation. As manufacturers increasingly seek efficiency and precision, automation plays a pivotal role in enhancing the SMT placement process. With the integration of intelligent systems and robotics, the capability to manage high volumes of complex assembly tasks has improved tremendously.

Automated placement machines, equipped with advanced vision systems, can now accurately position components with remarkable speed and reliability, reducing the margin for human error and ensuring higher quality in production.

Moreover, machine learning and artificial intelligence are becoming crucial in optimizing the SMT placement processes. These technologies enable systems to analyze production data and adapt in real-time, allowing for more agile responses to changes in production requirements or unexpected issues. As a result, manufacturers can achieve better resource utilization and lower operational costs. The trend towards automation not only streamlines the assembly line but also allows for more flexible manufacturing, where changes in designs or batch sizes can be accommodated with minimal disruption.

As the industry moves toward 2025, these advancements will continue to redefine the capabilities of SMT placement equipment, paving the way for smarter and more efficient factories.

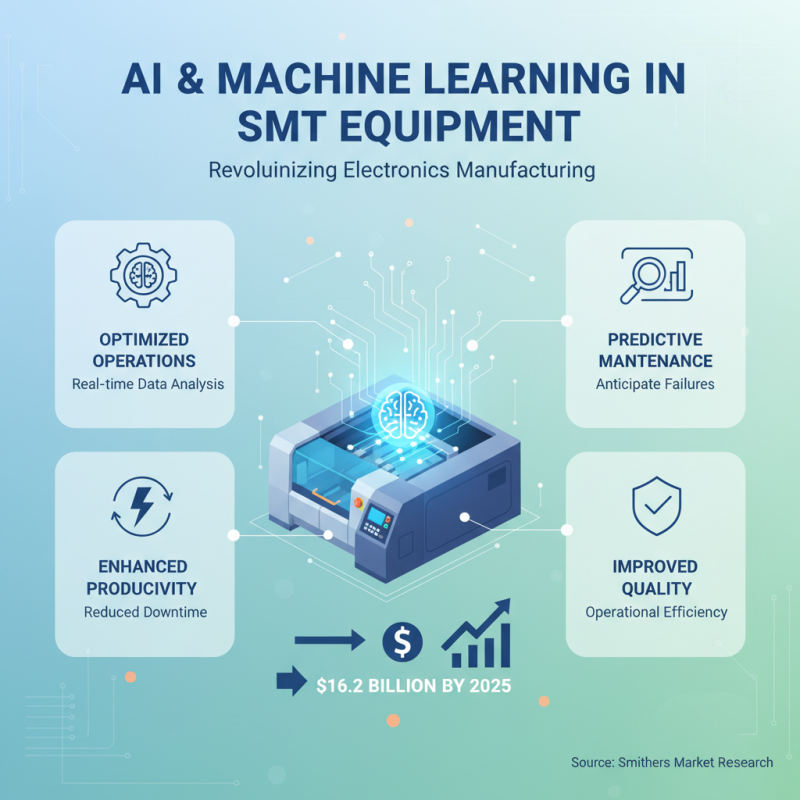

The integration of artificial intelligence (AI) and machine learning into Surface Mount Technology (SMT) equipment is revolutionizing the assembly process in electronics manufacturing. According to a recent market research report by Smithers, the global SMT equipment market is projected to reach $16.2 billion by 2025, with AI and machine learning playing a crucial role in driving this growth. These technologies enable machines to optimize their operations by analyzing real-time data, predicting potential failures, and suggesting adjustments to reduce downtime. This capability allows manufacturers to enhance productivity, quality, and operational efficiency.

Furthermore, AI-driven systems facilitate advanced analytics that enhance process control and inspection techniques. A report from ResearchAndMarkets indicates that the adoption of AI in the SMT sector has the potential to reduce production costs by up to 15% through improved yield rates and minimized scrap. Automated optical inspection (AOI) combined with machine learning algorithms can detect defects with greater precision than traditional methods, allowing companies to address issues proactively. This shift toward data-driven decision-making not only improves the overall quality of electronic assemblies but also shortens the time-to-market for new products, thereby enhancing competitive advantage in a rapidly evolving industry.

The SMT placement industry is undergoing remarkable transformations driven by advancements in technology and market demands. As we approach 2025, key trends are emerging that highlight the importance of automation, precision, and efficiency in the manufacturing process. According to a recent report by MarketsandMarkets, the global SMT market is expected to grow significantly, with an anticipated compound annual growth rate (CAGR) of around 8.5% from 2021 to 2026. This growth is largely attributed to innovations that enhance the speed and accuracy of component placement.

One notable trend is the increasing adoption of AI-driven solutions in SMT placement equipment. These innovations offer not only improved placement accuracy but also real-time monitoring of operational efficiency. According to industry experts, implementing AI technology can reduce defect rates by up to 30%, leading to significant cost savings for manufacturers. Additionally, the integration of machine learning algorithms is allowing companies to optimize their production processes, ensuring quicker turnaround times without sacrificing quality.

**Tips:** When considering new SMT placement equipment, prioritize systems that offer scalability and adaptability to accommodate future technologies. Regularly updating your equipment and incorporating training for operators on the latest advancements can also ensure optimal performance and productivity. Embracing these innovations can position manufacturers to stay competitive in the rapidly evolving electronics market.