-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In the rapidly evolving electronics industry, the demand for high-reliability soldering processes has surged. A Vacuum Reflow Oven stands out among various soldering technologies, offering precise temperature control and enhanced solder joint quality. According to a recent report by TechNavio, the global vacuum reflow oven market is expected to grow at a compound annual growth rate (CAGR) of 8.16% from 2022 to 2026.

Experts in the field, like Dr. Ethan Schwartz, emphasize the advantages of this technology: "Using a Vacuum Reflow Oven can significantly reduce solder defects and improve product longevity." This statement reflects the growing acknowledgment of vacuum reflow systems, especially in industries that prioritize quality and reliability. However, implementing this technology is not without challenges. Proper training and integration into existing processes can be complex. There is also the cost factor, which may be a barrier for some manufacturers.

Adopting a Vacuum Reflow Oven requires careful consideration. While the benefits are clear, organizations must weigh the initial investment and ongoing operational costs against long-term gains. This reflection is essential for companies looking to innovate while maintaining efficiency and quality in their production lines.

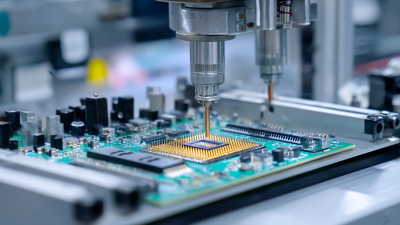

A vacuum reflow oven is a specialized equipment used in the electronics manufacturing industry. It plays a crucial role in soldering components onto printed circuit boards (PCBs). This oven operates by removing air from the chamber, creating a vacuum environment during the heating process. As a result, it helps achieve uniform heating and allows better wetting of solder.

In this process, solder paste is applied to areas where components will be placed. The vacuum reflow oven heats the PCB, enabling the solder to melt. The vacuum helps to eliminate voids and promotes better adhesion. However, the need for a consistent vacuum level can be challenging. If not maintained, defects may occur in solder joints.

**Tips:** Regularly check the vacuum pressure. Inconsistent pressure can lead to poor results. Monitor temperature profiles closely. An incorrect temperature might ruin components or the PCB. Lastly, ensure proper maintenance of the oven. Neglecting it could lead to increased downtime.

Achieving optimal results with a vacuum reflow oven requires careful attention to detail. Operators often face challenges, like aligning components accurately. A slight misalignment can result in wasted materials. Testing several profiles can also be frustrating, as it may take multiple attempts to find the right settings. Embracing these learning moments can improve the overall process.

A vacuum reflow oven is essential in electronics manufacturing. Its principle focuses on melting solder in a controlled environment. The oven uses heat and vacuum to ensure quality solder joints. It effectively removes air, reducing oxidation. This process is crucial for sensitive components.

The operation involves several phases. Firstly, the PCB is heated gradually. Once the right temperature is reached, a vacuum is created. The absence of air helps prevent bubbling in the solder. This leads to a more reliable connection between components. The entire process requires precise timing and temperature control. If not done correctly, issues arise.

Users often find that achieving optimal results can be challenging. Temperature fluctuations may lead to improper soldering. Sometimes, vacuum levels aren't sufficient, causing defects. It’s vital to monitor each cycle closely. Continuous adjustments are necessary for improvement. Each mistake teaches valuable lessons on soldering quality.

A vacuum reflow oven is essential in the electronics industry. Its main components include a vacuum chamber, heating elements, and a control system. The vacuum chamber reduces oxidation during soldering. This is crucial for ensuring strong, reliable connections in circuit boards.

Heating elements are typically infrared or convection-based. They must provide precise temperature control for varying substrates. According to industry data, effective temperature management can improve solder joint quality by up to 30%.

The control system monitors the entire process. It ensures uniform heating and maintains vacuum pressure. However, one challenge is the potential for uneven heat distribution. This can lead to defective solder joints. Continuous monitoring is needed to overcome this issue. Balancing efficiency and quality remains a key concern for manufacturers.

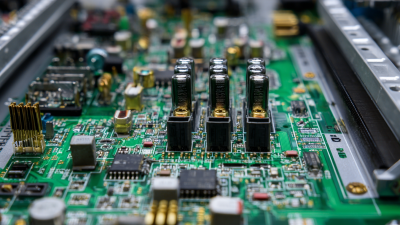

Vacuum reflow ovens have gained popularity in manufacturing due to their significant advantages. These ovens create a vacuum environment during the soldering process. This reduces oxidation and ensures a cleaner solder joint. According to a report by IPC, approximately 30% of defects in electronic assemblies are due to solder quality issues. Using vacuum reflow ovens can markedly improve solder quality.

The benefits extend beyond cleaner soldering. These ovens enhance thermal efficiency, leading to better temperature control. Prior studies show that consistent temperature profiles can increase yield rates by about 20%. The vacuum minimizes voids in solder joints, which can lead to greater reliability in electronic devices. Some manufacturers have reported a notable reduction in product failures when using this technology.

However, it’s important to note that vacuum reflow ovens require precise programming. Improper settings can lead to undercooked joints or thermal damage. Training personnel is crucial for optimal performance. As industries adopt this technology, attention to detail will determine its success. Embracing vacuum reflow technology presents opportunities and challenges alike. Balancing cost and quality remains an ongoing concern.

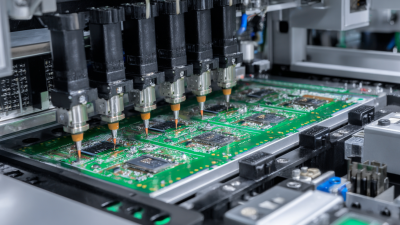

Vacuum reflow ovens are essential in electronics production. They create a controlled environment that enhances soldering processes. These ovens remove air, preventing oxidation. This leads to stronger electronic connections. They work by heating components in a vacuum for optimal results.

In the assembly of printed circuit boards (PCBs), vacuum reflow ovens shine. They are used to bond chips and components securely. The unique process allows for precise temperature control. This can reduce defects, but not always. Some experiments showed inconsistent results.

Manufacturers often face challenges with varying material types. Not all components react the same way in a vacuum. Adjusting parameters can be tricky. Engineers may require extensive testing to achieve consistent quality. Balancing efficiency and reliability remains an ongoing task.

| Feature | Description |

|---|---|

| Temperature Control | Accurate temperature management for optimal soldering. |

| Vacuum Functionality | Reduces oxidation and improves solder flow. |

| Applications | Used in high-density PCBs, small component soldering. |

| Common Industries | Electronics manufacturing, aerospace, automotive. |

| Advantages | Improved solder joint reliability and reduced defects. |

| Disadvantages | Higher initial investment and operational cost. |